Vacuum filling machine convenient to overhaul

A filling machine and vacuum technology, which is applied in the field of vacuum filling machines, can solve the problems of leaking, troublesome and incapable of filling the hose, and achieve the effect of convenient and quick maintenance and improvement of efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

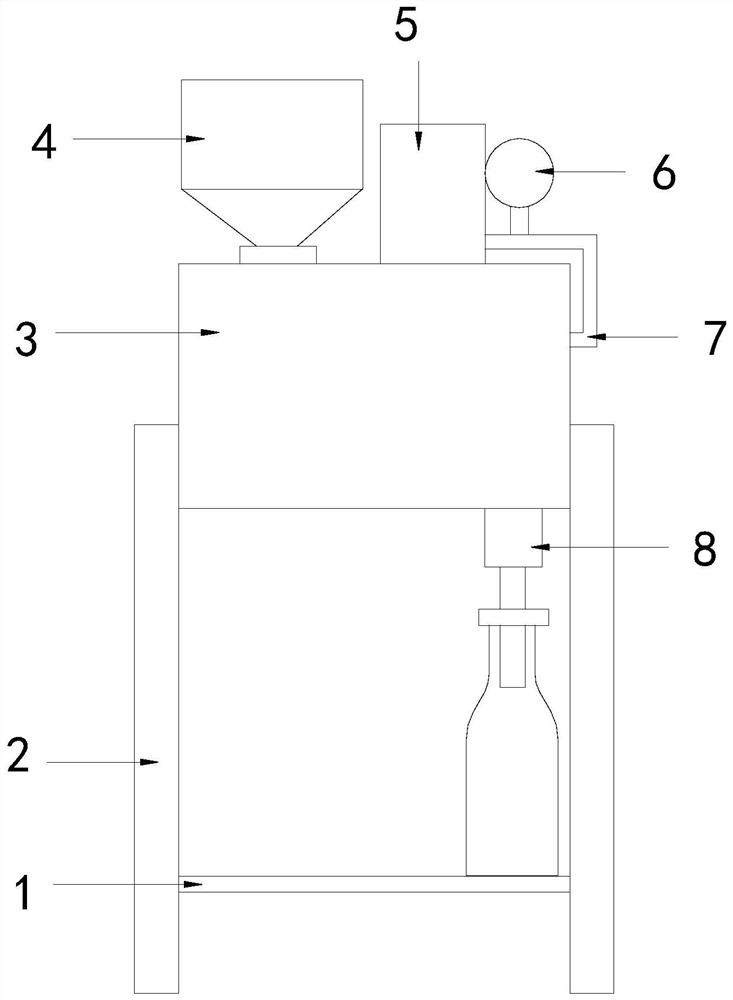

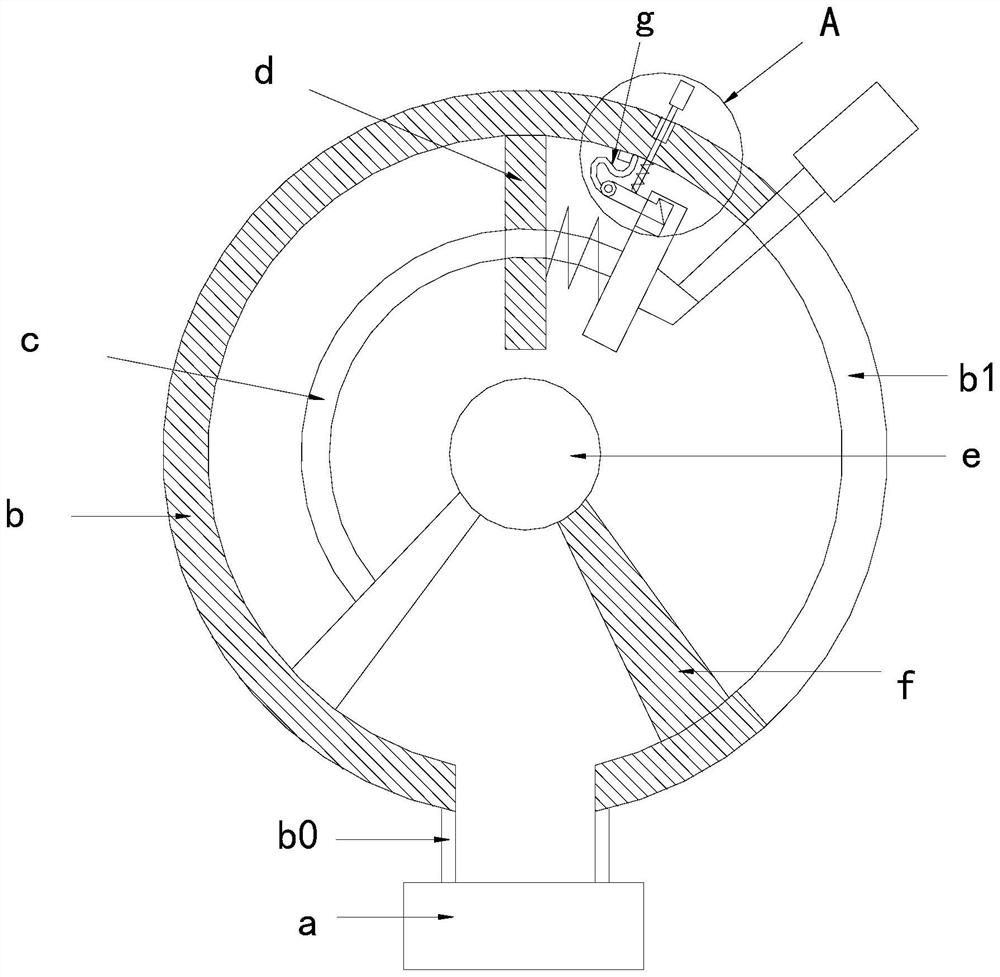

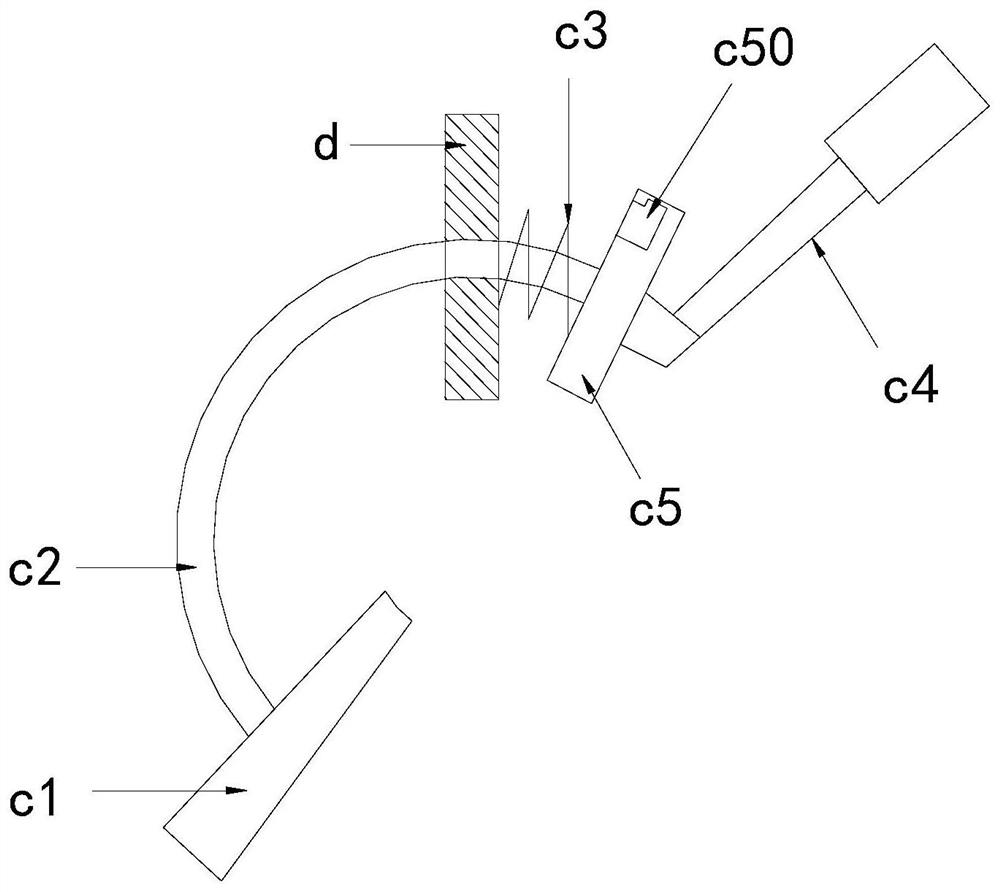

[0026]SeeFigure 1-3 , The present invention provides a technical solution for a vacuum filling machine that is convenient for maintenance: its structure includes a pallet 1, a support 2, a working chamber 3, a barrel 4, a vacuum pump 5, a maintenance structure 6, a rubber tube 7, and a valve 8. The two sides of the cavity 3 are welded with brackets 2 respectively, and the bottom of the working cavity 3 is equipped with a valve 8. The supporting plate 1 is arranged under the valve 8 and connected with the bracket 2, and the top of the working cavity 3 is equipped with a barrel 4 , Vacuum pump 5, said vacuum pump 5 is connected to working chamber 3 through a hose 7, said hose 7 communicates with an overhaul structure 6, said overhaul structure 6 includes an overhaul valve a, a housing b, a movable part c, and a fixed plate d , The fixed shaft e, the sealing plate f, the bottom of the shell b is provided with a through hole b0, the through hole b0 is connected to the hose 7 through the...

Embodiment 2

[0029]SeeFigure 1-4, The present invention provides a technical solution for a vacuum filling machine that is convenient for maintenance: its structure includes a pallet 1, a support 2, a working chamber 3, a barrel 4, a vacuum pump 5, a maintenance structure 6, a rubber tube 7, and a valve 8. The two sides of the cavity 3 are welded with brackets 2 respectively, and the bottom of the working cavity 3 is equipped with a valve 8. The supporting plate 1 is arranged under the valve 8 and connected with the bracket 2, and the top of the working cavity 3 is equipped with a barrel 4 , Vacuum pump 5, said vacuum pump 5 is connected to working chamber 3 through a hose 7, said hose 7 communicates with an overhaul structure 6, said overhaul structure 6 includes an overhaul valve a, a housing b, a movable part c, and a fixed plate d , The fixed shaft e, the sealing plate f, the bottom of the shell b is provided with a through hole b0, the through hole b0 is connected to the hose 7 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com