System and method for controlling rotating speed of variable-frequency compressor

A variable frequency compressor and rotational speed control technology, which is applied in pump control, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of poor noise in refrigerators, achieve the effect of eliminating errors, eliminating abnormal noise, and improving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

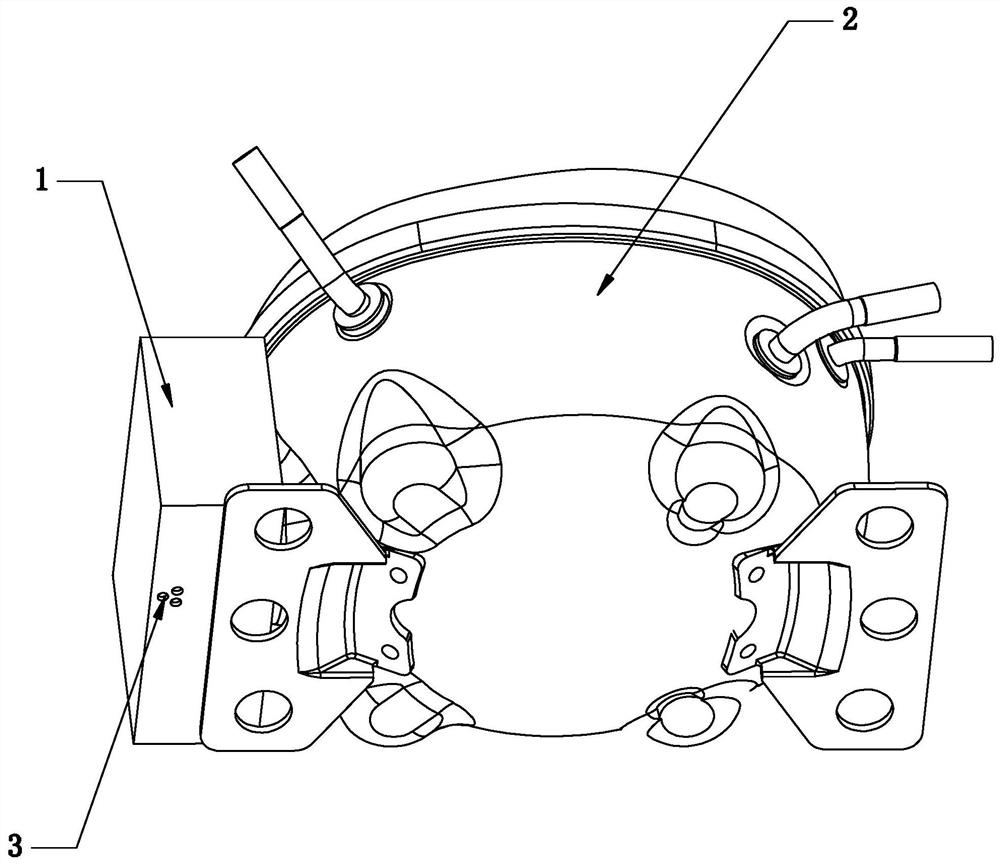

[0029] In this embodiment, a variable frequency compressor speed control system, such as figure 1 As shown, it includes a control box 1 and a controller, the control box is arranged on the compressor 2, the control box is provided with a sound sensor, the controller is respectively connected to the sound sensor and the compressor, the control box is provided with a sound transmission hole 3, and the controller Set in the control box.

[0030] The sound sensor collects the sound of the frequency conversion compressor running in the refrigerator at each speed range, and the controller selects the speed at which the sound is the smallest in each speed range as the optimal operating speed of the compressor in this speed range. During operation, the controller controls the compressor to run at the optimum speed in this speed range, effectively avoiding the abnormal noise of the refrigerator and eliminating the abnormal noise caused by the difference of each compressor.

[0031] Co...

Embodiment 2

[0041] Compared with Embodiment 1, this embodiment is different in that the speed control system of the variable frequency compressor is different. The speed control system of the variable frequency compressor includes a refrigerator main control board and a sound sensor, and the refrigerator main control board is respectively connected with the sound sensor and the compressor.

Embodiment 3

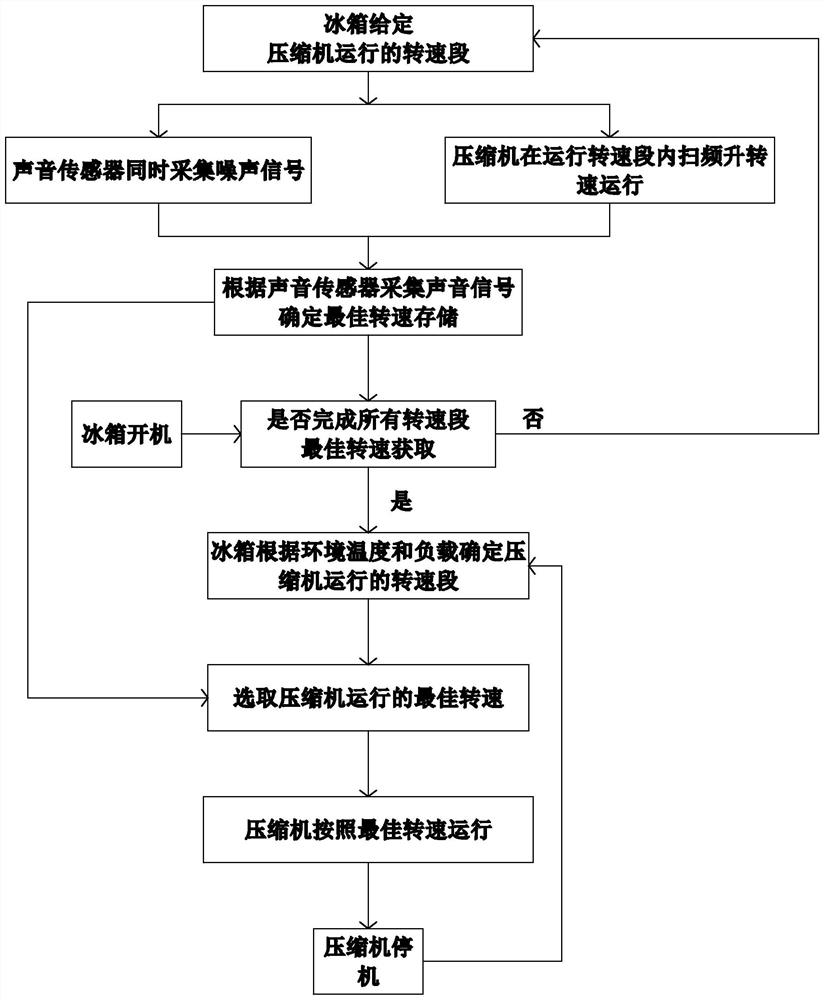

[0043] In this embodiment, a method for controlling the speed of an inverter compressor includes the following steps:

[0044] S1: After the refrigerator is turned on, it is judged whether the acquisition of the best rotational speed of all rotational speed segments is completed, if not, proceed to step S11, and if so, proceed to step S2;

[0045] S11: given compressor speed segment;

[0046] S12: make the compressor run in a given speed range by sweeping up the speed and obtain the noise generated by the operation of the refrigerator in real time, and at the same time establish the corresponding relationship between the speed of the compressor and the noise generated by the equipment including the compressor;

[0047] S13: Select the compressor speed when the noise is the least to be the best speed in the given speed range;

[0048] S2: Determine the rotational speed segment of the compressor according to the ambient temperature and load, and obtain the optimal rotational sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com