Drum type washing machine

一种滚筒式洗衣机、洗衣机的技术,应用在其他洗衣机、洗衣机的控制装置、洗涤装置等方向,能够解决振幅不大、浪费、不能检测出异常振动等问题,达到防止异常振动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

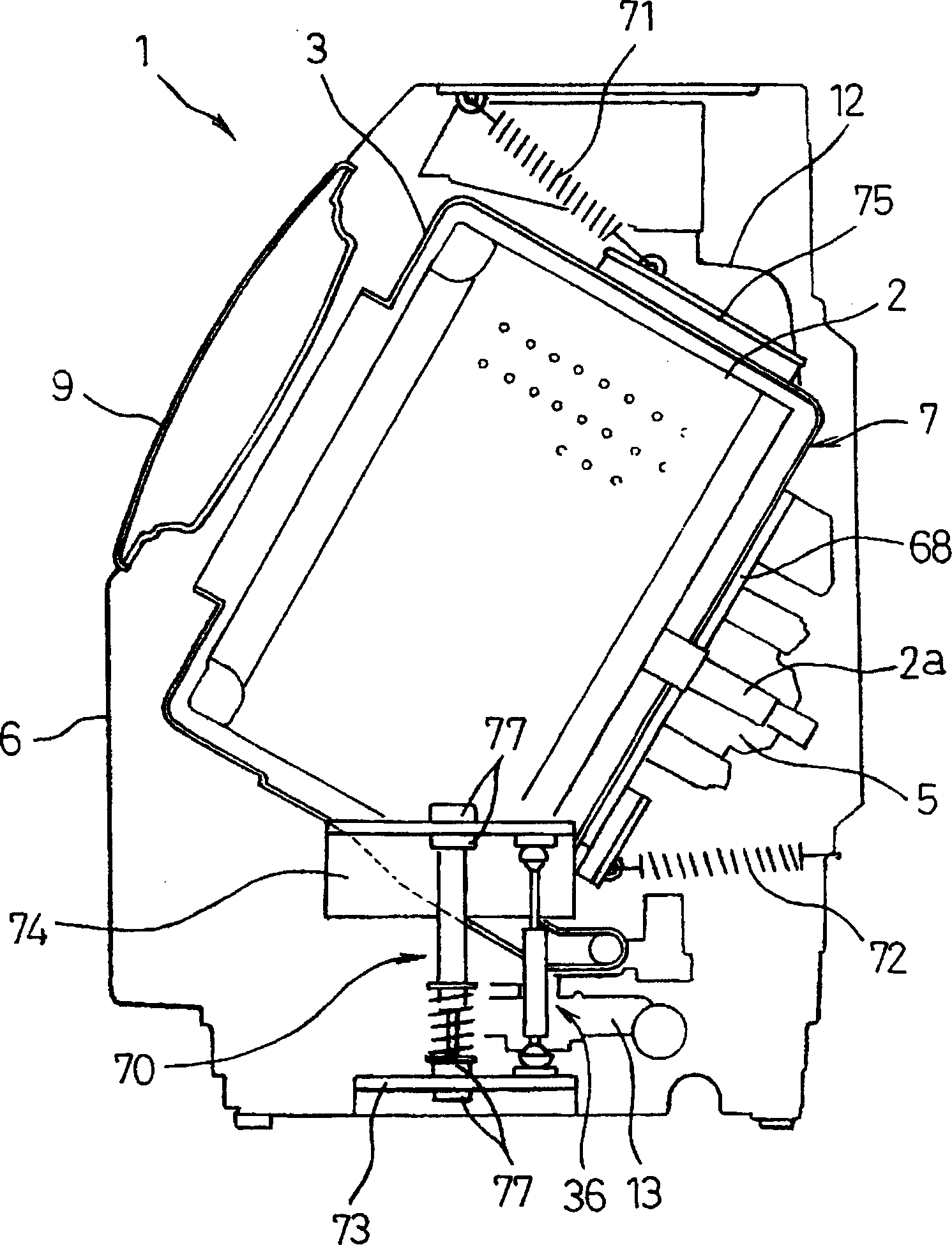

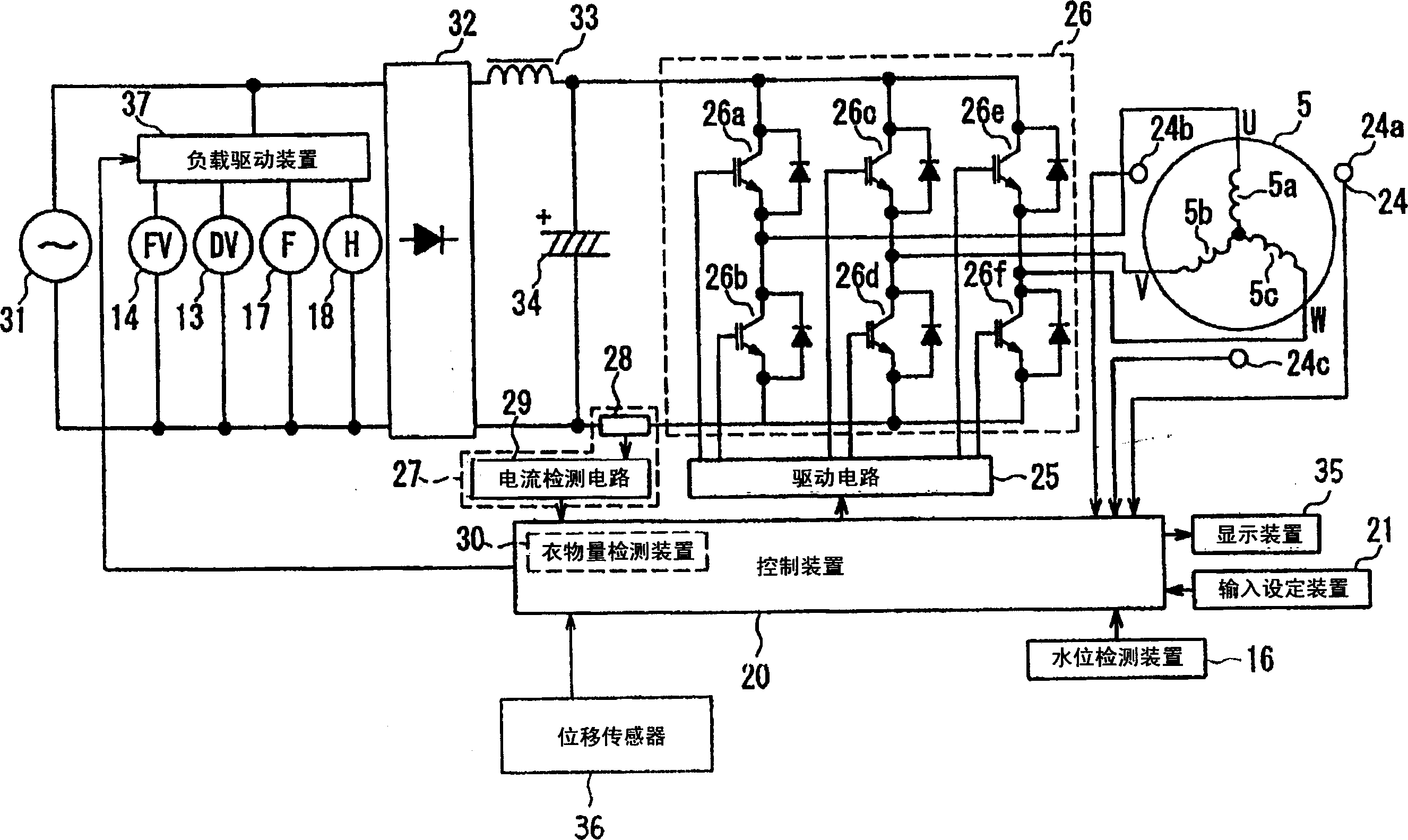

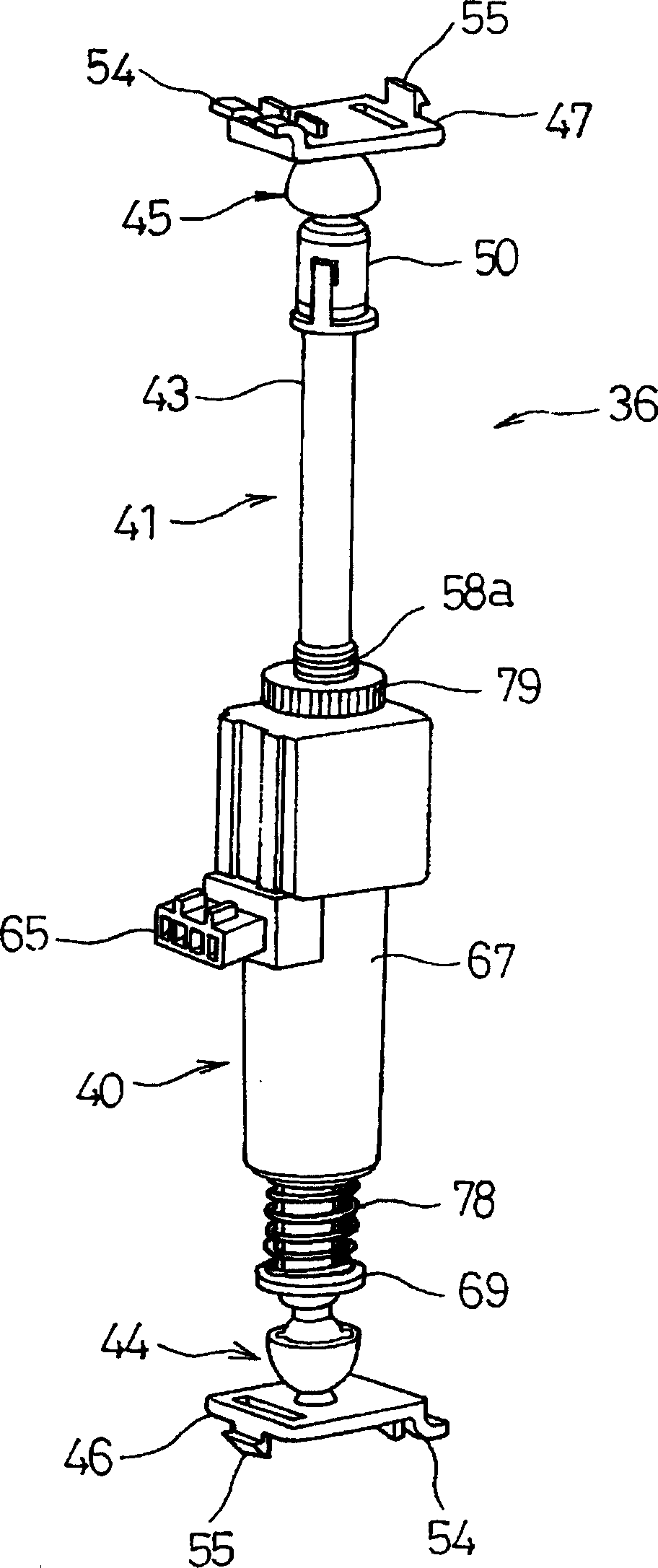

[0024] figure 1 It is a schematic diagram of the main structure of the drum-type washing machine 1 shown in an embodiment of the present invention. The washing machine body 6 is provided with a water tub 3, in which a rotating drum 2 is housed, and the rotating shaft 2a of the rotating drum 2 is supported by a bearing 68 arranged on the back side of the water tub 3, and the rotating shaft 2a is connected with the drum driving motor 5 , The bucket assembly 7 is set to a tilted state in which the front portion is upturned. Although the center of gravity of the bucket assembly 7 is relatively backward due to the heavy components such as the bearing 68 and the drum drive motor 5 being installed on its back side, it is in an unstable state, but the anti-vibration damping member 70 is in a relatively unstable state. Its center of gravity is close to the lower part of the front side to support the bucket assembly 7, and the first coil spring 71 erected between the upper metal suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com