Oilless reciprocating air compressor

An air compressor, reciprocating technology, applied in the direction of liquid variable displacement machinery, mechanical equipment, engine components, etc., can solve the problems of reducing sliding performance and anti-seizing performance, and not improving the life of piston rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

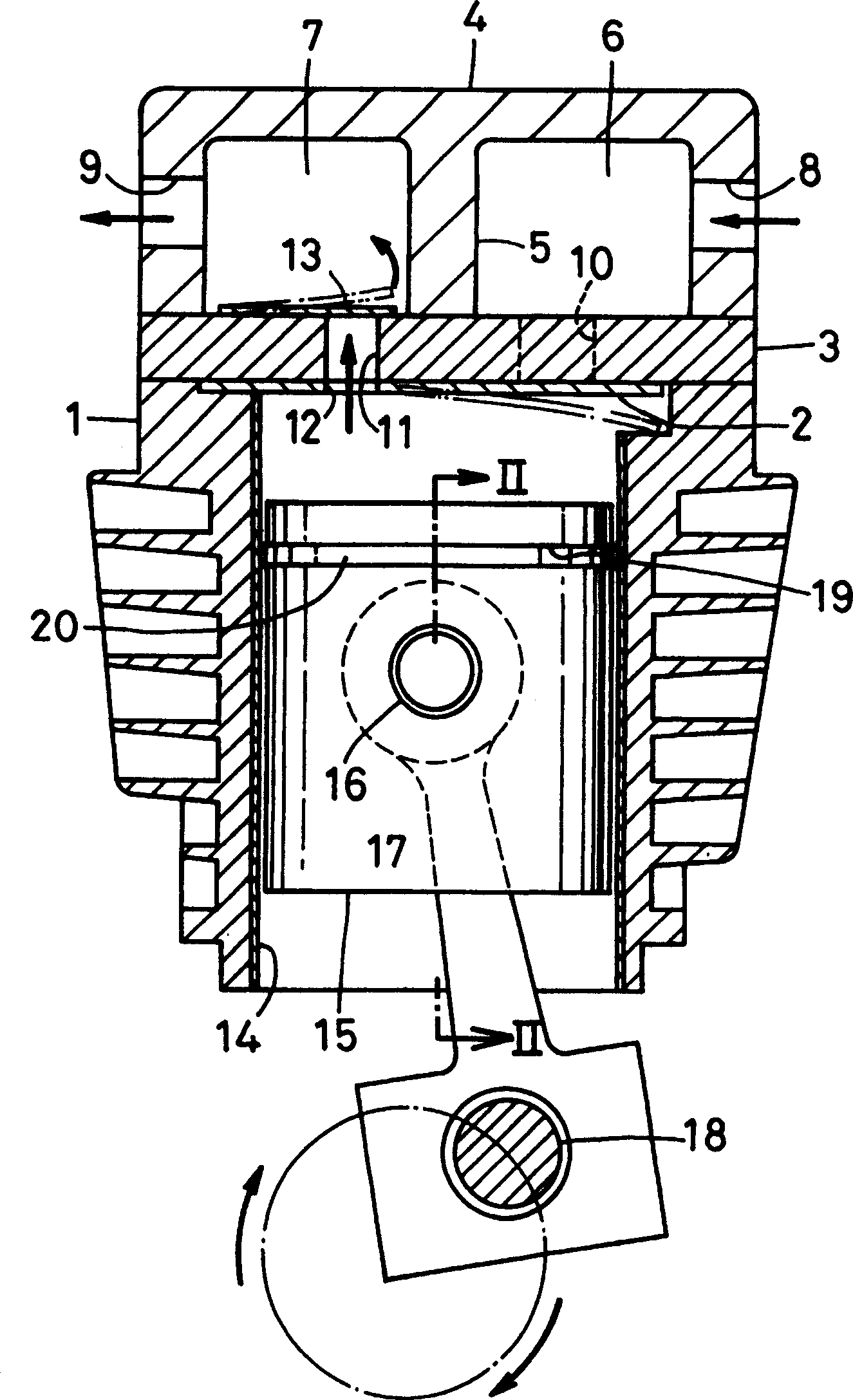

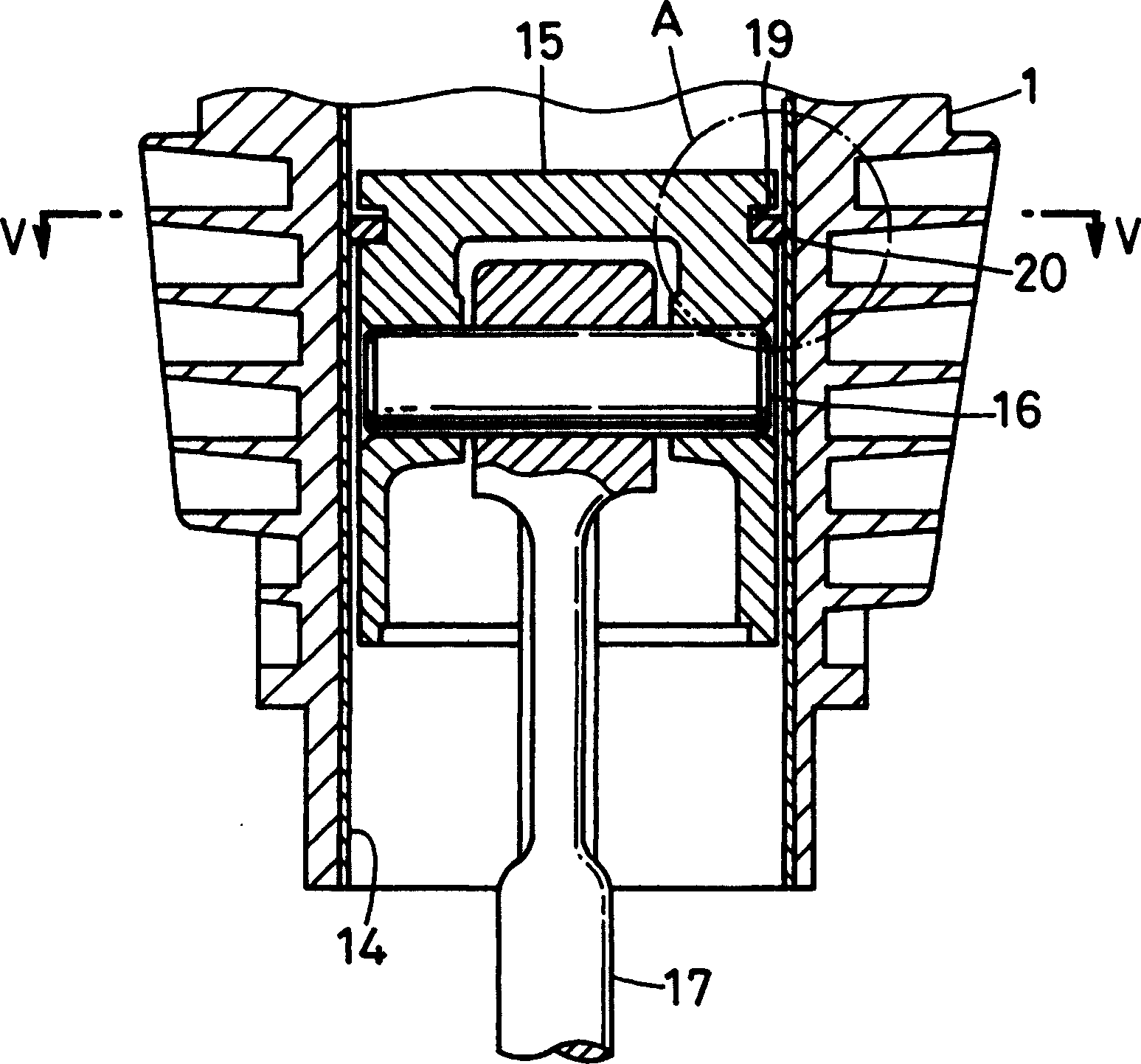

[0028] The oil-free reciprocating air compressor according to the present invention has the following structural features:

[0029] cylinder

[0030] Size: hole 50mm, 75mm

[0031] Material: Al or Al alloy

[0032] Inner surface: SiC coating formed by coating

[0033] The hardness of the coating: Vickers hardness (Hv) 1600-2400

[0034] The thickness of the coating: 15μm

[0035] Average surface roughness Ra: 0.05-0.5μm mirror polished

[0036] piston

[0037] Size: outer diameter 50mm, 75mm, height 50mm, 75mm

[0038] Material: Composite material of COPNA resin and graphite

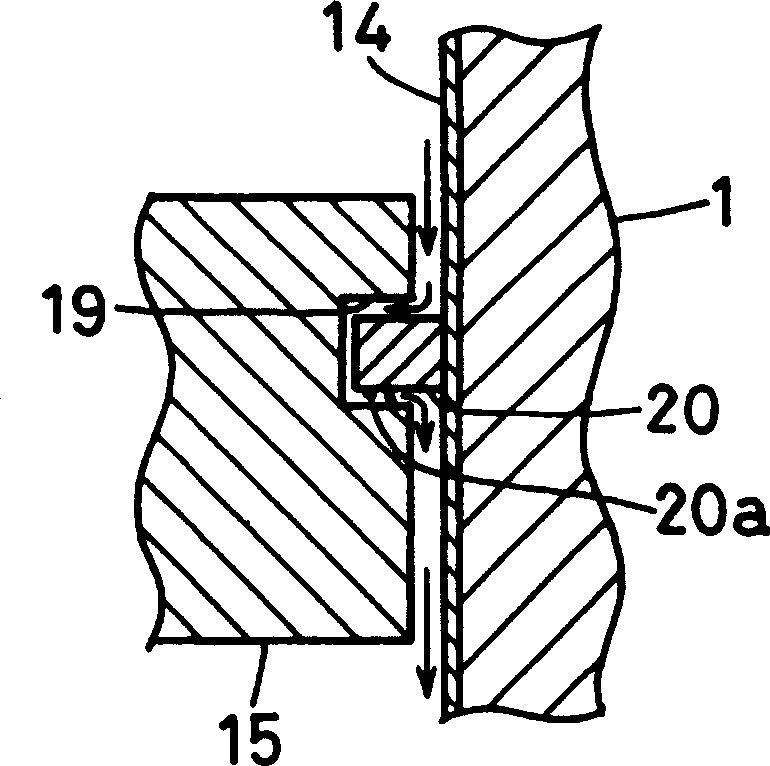

[0039] piston ring

[0040] Size: nominal diameter 50mm, 75mm, width 4.53mm, thickness 4.0mm

[0041] Material: Composite material of polytetrafluoroethylene resin (TeflonTM) and graphite

[0042] Features: Tensile strength 13-35MPa, compressive strength 10-13MPa, Vickers hardness (Hv) 360-400

[0043] The COPNA resin from which the piston is made is a thermosetting resin prepared by crosslink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com