Pipe jacking construction method and pipe pushing jack applied to method

A construction method and pipe jacking machine technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipeline laying and maintenance, etc., can solve the problems of mud cost and difficulty increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

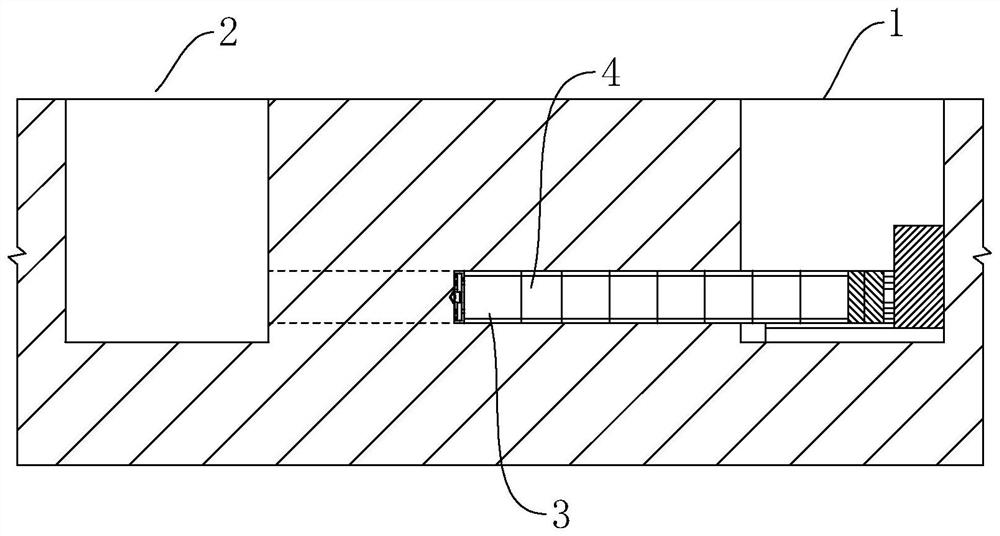

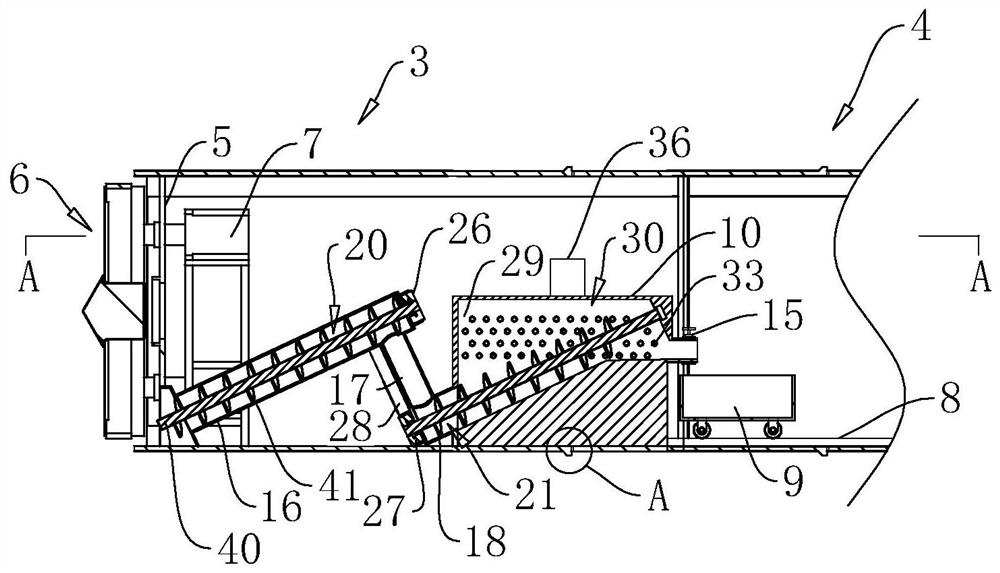

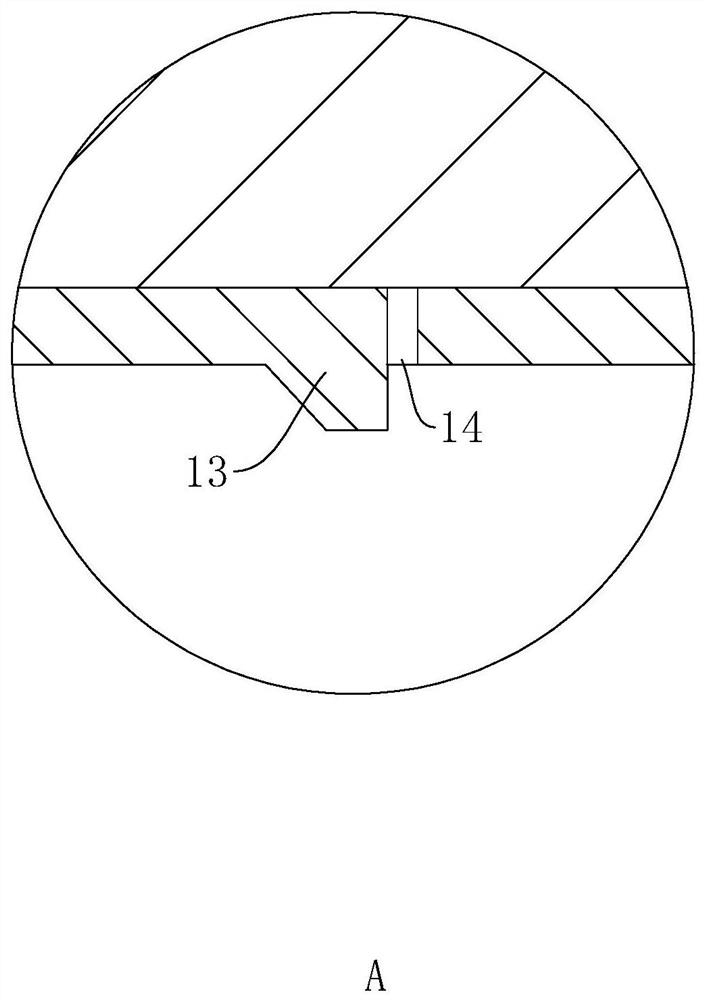

[0042] Attached to the following Figure 1-5 This application will be described in further detail.

[0043] refer to figure 1 , 2 , the pipe jacking machine is connected to the end of the pipe 4 closest to the receiving well 2, including the body 3, the mounting plate 5, and the soil stirring mechanism. The cross-sectional size of the pipe 4 is a large-section pipe with a size of 7.5m*5.4m. The soil-ploughing mechanism includes a soil-plucking blade 6 for crushing the soil body and a soil-plucking motor 7 for driving the soil-plucking blade 6 to rotate. The mounting plate 5 is vertically fixedly connected to the inside of the body 3 and is arranged away from the pipe 4. The thickness of the mounting plate 5 is arranged. Two sides of the body 3 separate the soil pressure bin for accommodating the soil-ploughing blade 6 and the accommodation bin for installing the soil-ploughing motor 7 , and the accommodation bin is in communication with the pipe 4 . The tiller blade 6 is l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap