Square battery charge-discharge test motion mechanism and application method

A technology for charge and discharge testing and prismatic batteries, which is applied to battery pack components, electrical measuring instrument components, circuits, etc., can solve problems such as waste of battery testing equipment resources, and reduce human and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

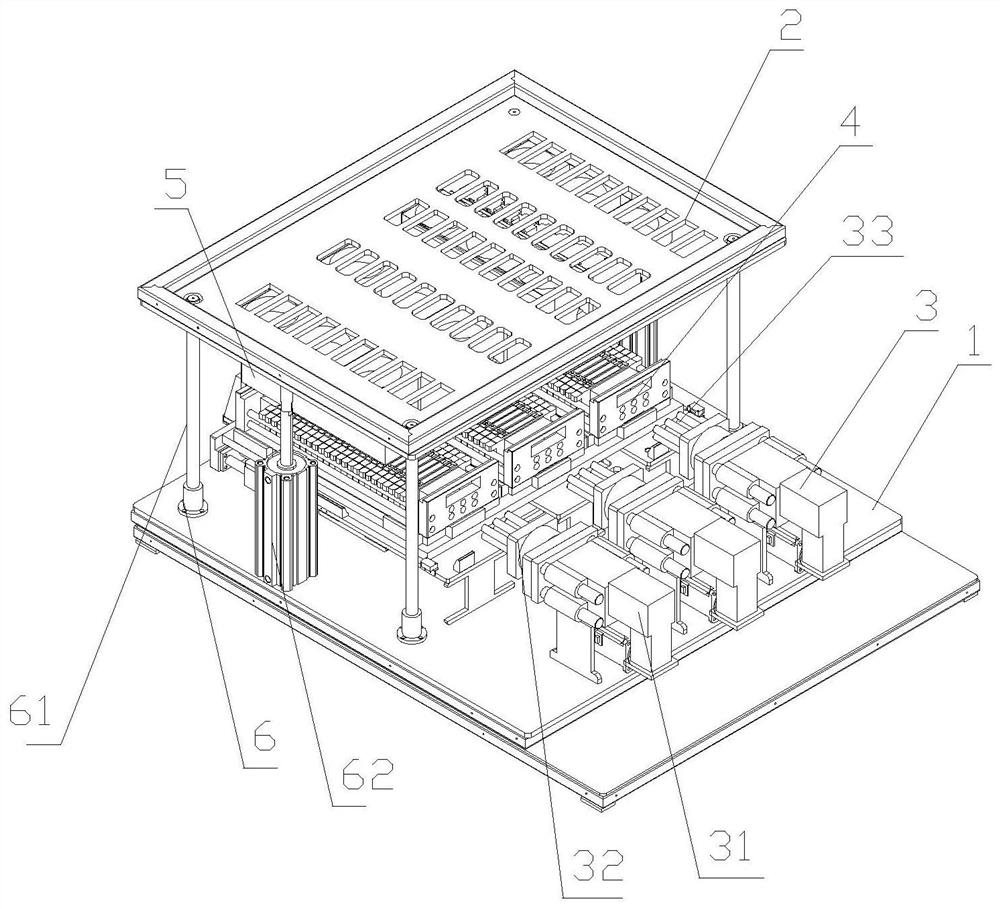

[0038] Embodiment 1 A prismatic battery charge and discharge test movement mechanism according to the present invention includes:

[0039] The bottom plate 1 is installed, and an installation plane is arranged on the surface, which is used to support the voltage regulation drive mechanism and the battery tray mechanism of the square battery charge and discharge test movement mechanism;

[0040] The pressure regulating drive mechanism 3 is arranged on the installation plane, including a drive part and a push part, wherein the drive part is fixed on the installation plane, and the driving end of the drive part is aligned with the battery tray mechanism, and stretches in a direction parallel to the installation plane , used to drive the pushing part to move; the pushing part is installed on the driving end of the driving part, and is used to pressurize or release the battery tray mechanism;

[0041] The battery tray mechanism 4 is arranged on the installation plane, and includes ...

Embodiment 2

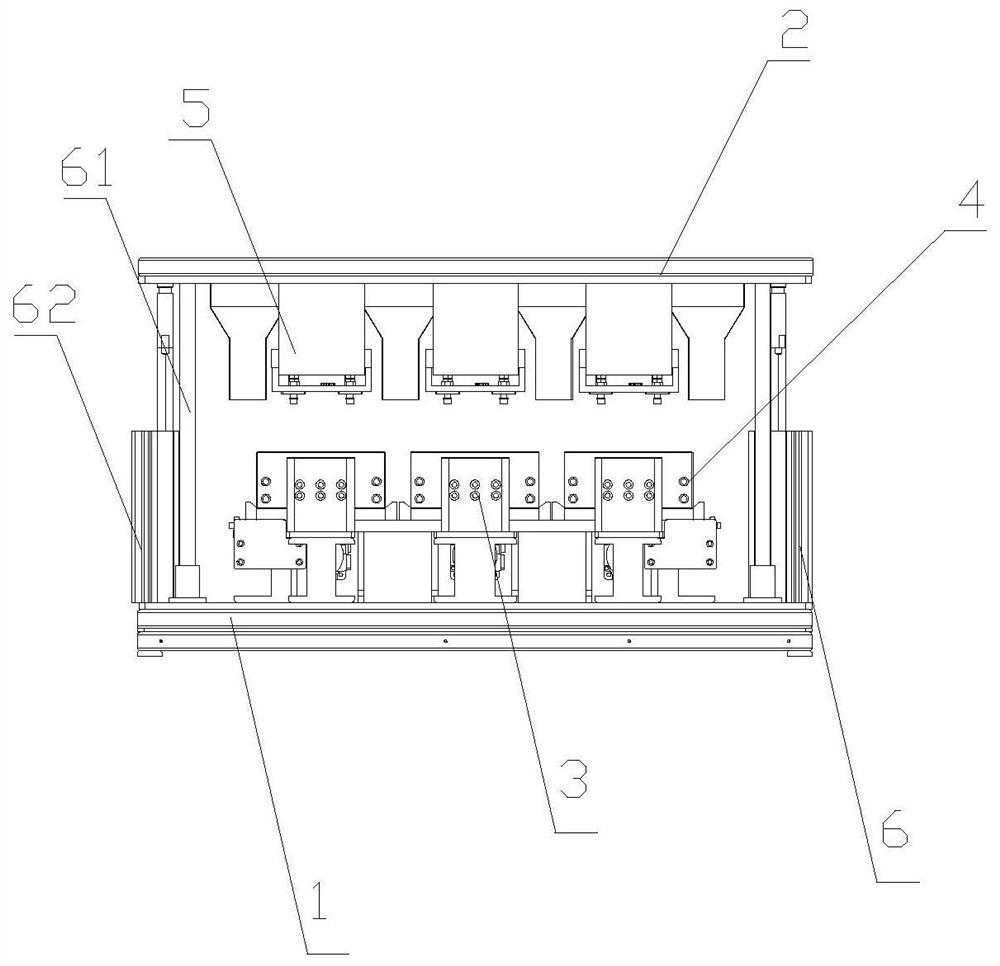

[0050] Embodiment 2 The charging and discharging test movement mechanism of the square battery of the present invention includes a mounting base plate 1 for supporting, a voltage regulating driving mechanism 3 for pressurizing and releasing the battery tray mechanism, and a driving mechanism for carrying the square battery. The battery tray mechanism 4, the positive and negative electrode conduction mechanism for contacting the positive and negative poles of the square battery, wherein the positive and negative electrode conduction mechanism includes a top plate 2 for installing and supporting the probe mechanism, for connecting with the positive and negative poles of the square battery A probe mechanism 5 for contacting the positive and negative poles of the square battery and a jacking mechanism 6 for driving the installation top plate and the probe mechanism to move up and down, wherein:

[0051] The installation bottom plate and the installation top plate can be aluminum pl...

Embodiment 3

[0062] Embodiment 3 An application method of a square battery charging and discharging testing motion mechanism according to the present invention, comprising the following steps:

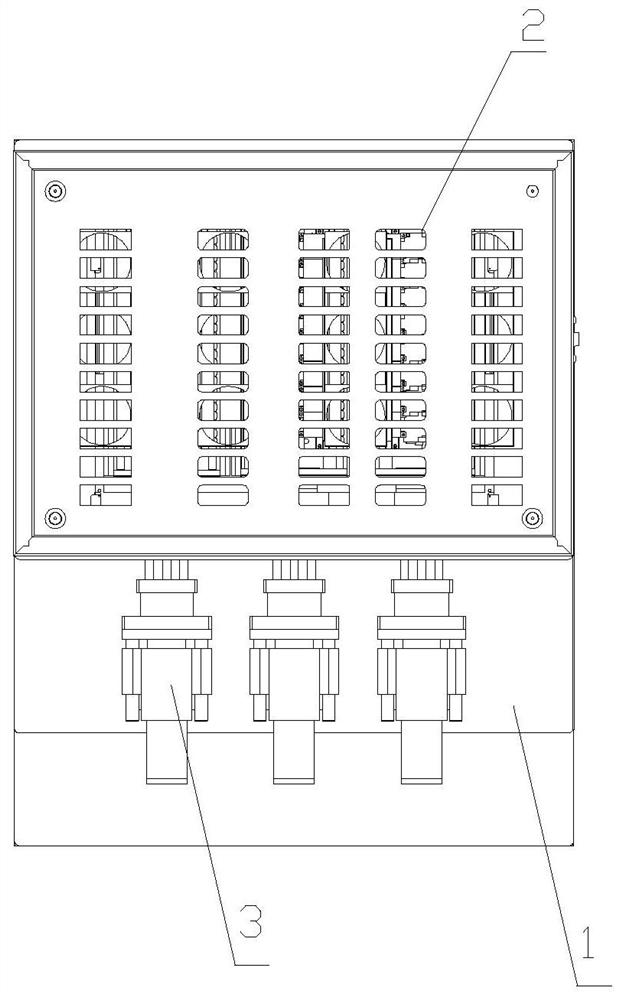

[0063] 1) Place the battery tray 43 containing seventy-two square batteries on the bottom plate of the battery tray mechanism 4, which is supported by the bottom plate 41 of the battery tray mechanism 4, and is limited by the stopper 42. When the battery After the tray 43 is in place, the pressure regulating drive mechanism 3 starts to act;

[0064] 2) The speed reducer 31 of the voltage regulating drive mechanism 3 performs power action to push the clamping shaft 33 to move. When the tight hole 4321 cooperates, push the front and rear pushing block 433 to move, and then pressurize the square battery;

[0065] 3) After the square battery is pressurized, the distance between the batteries changes, and the position data of each battery is obtained by the CCD camera 53;

[0066] 4) The position data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com