An underground pipe corridor robot and wireless ad hoc network system

A wireless ad hoc network and robot system technology, applied in the field of underground pipe gallery robots and wireless ad hoc network systems, can solve problems such as low efficiency, processing time delay, channel conflict frequency bands, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

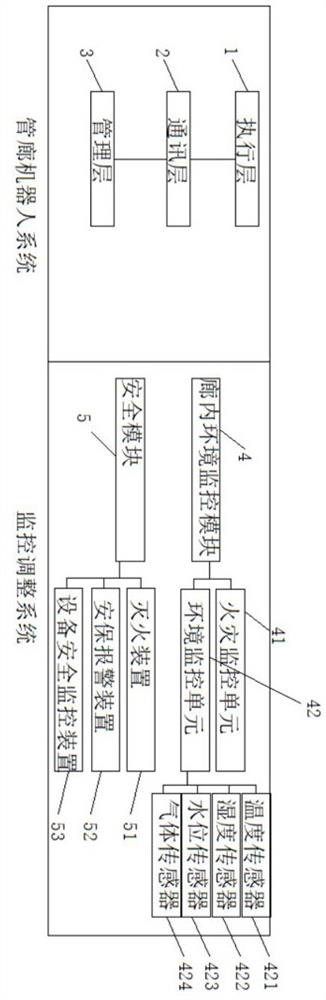

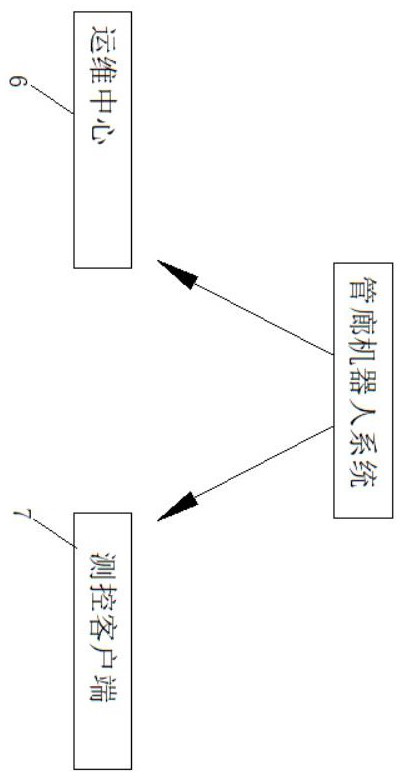

[0022] like Figure 1 to Figure 2 As shown, an underground pipe gallery robot and wireless ad hoc network system, including a pipe gallery robot system and a monitoring and adjustment system, the pipe gallery robot system is used to inspect and report underground pipe gallery inspection data, and the monitoring and adjustment system is used for Analyze the detection data, generate preset messages of the detection data and monitor the environmental status in the underground pipe gallery, characterized in that: the pipe gallery robot system includes execution layer 1, communication layer 2 and management layer 3, and execution layer 1 is patrol inspection For robots, the communication layer 2 is the communication node system distributed in the underground corridor, and the management layer 3 is the control terminal;

[0023] The communication node is a wireless communication system, and the monitoring and adjustment system is connected to the management layer 3 through the commu...

Embodiment 2

[0036] The management layer 3 includes a three-dimensional drawing module, a decomposition module, a summary module, a general control module and a communication module.

[0037] The three-dimensional drawing module is used for the site layout of the design drawing of the underground pipe gallery, and is used to draw the site layout model of the underground pipe gallery. The three-dimensional drawing module is connected with the decomposition module.

[0038] The decomposition module is used to decompose the detection tasks of the underground pipe gallery. The decomposition module creates detection nodes in the underground pipe gallery. In the secondary detection stage and the tertiary detection stage, the decomposition module is connected with the summary module.

[0039]The summary module is used for the inspection and safety control of the underground pipe gallery. The summary module summarizes the major hazards at each stage in combination with the construction conditions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com