Magnetic high-speed sorting device

A sorting device and high-speed technology, applied in sorting and other directions, can solve the problems of complex installation, round belt elongation, high cost, etc., and achieve the effect of improving the sorting speed of goods, improving production efficiency, and reducing manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

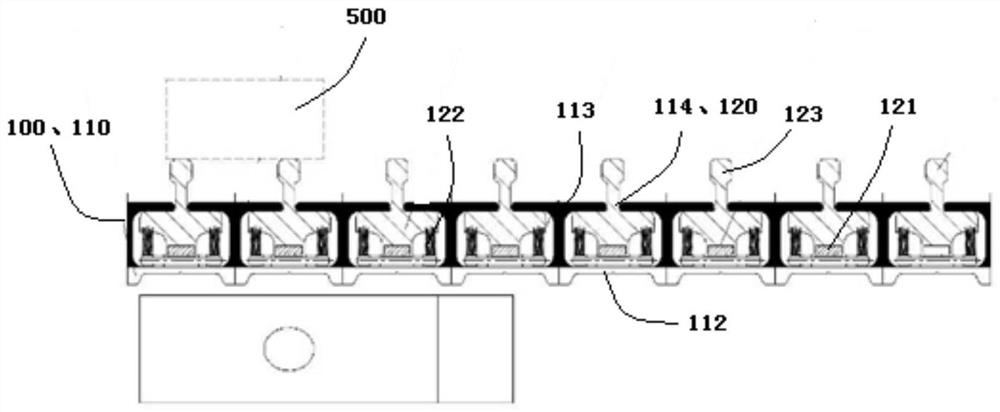

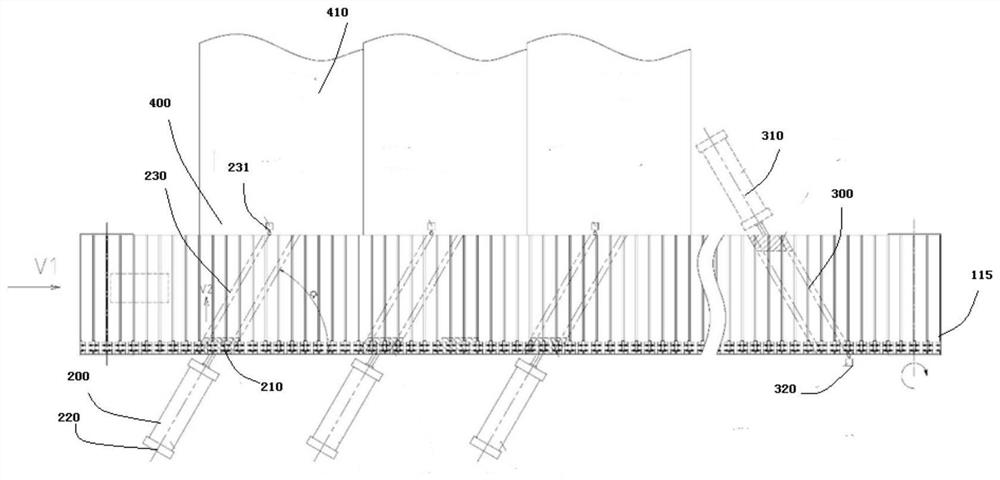

[0018] Such as figure 1 The shown magnetic high-speed sorting device 100 includes a toothed conveyor belt 110 with several racks 111 at the bottom, and a T-shaped baffle 113 is installed on the rack belt surface 112 corresponding to the racks 111 .

[0019] An empty slot 114 is left between every two T-shaped baffle plates 113 , and a slider trolley 120 is installed in the empty slot 114 . The slider dolly 120 can move back and forth in the empty slot, and the push rod 123 on the top of the slider dolly 120 can push the goods forward along the empty slot 114, and also plays a guiding role.

[0020] A spring 122 controlled by an armature 121 is arranged inside the slider trolley 120 , and a push rod 123 is arranged on the top of the slider trolley 120 , and the cargo 500 is pushed forward and guided by the push rod 123 .

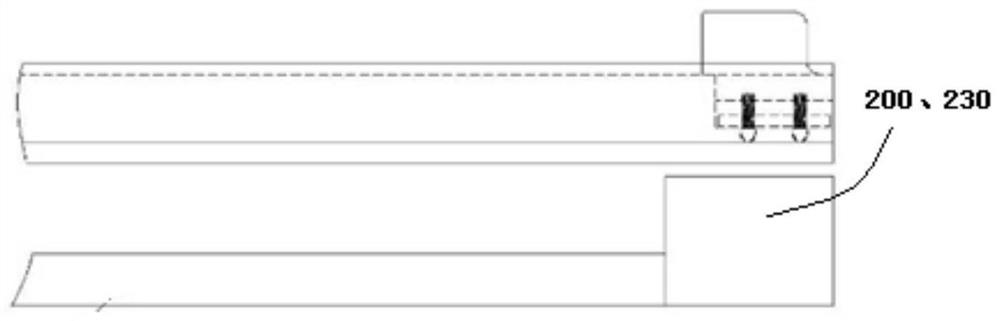

[0021] Below the toothed conveyor belt 110, several working magnetic mechanisms 200 are obliquely installed, and the electromagnet 210 of the working magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com