A kind of precision testing equipment and using method of computer pcb main board

A technology for PCB motherboard and testing equipment, applied in the field of precision testing equipment for computer PCB motherboards, can solve the problems of high labor intensity and inconvenience in automatic placement of PCB boards, and achieve the effects of reducing labor, good sorting effect, and fast collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

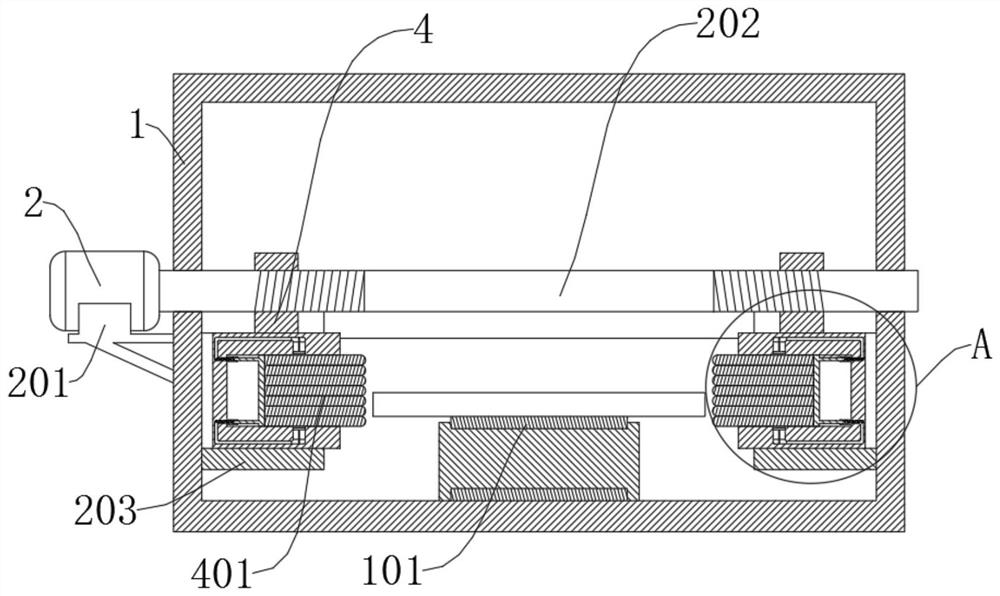

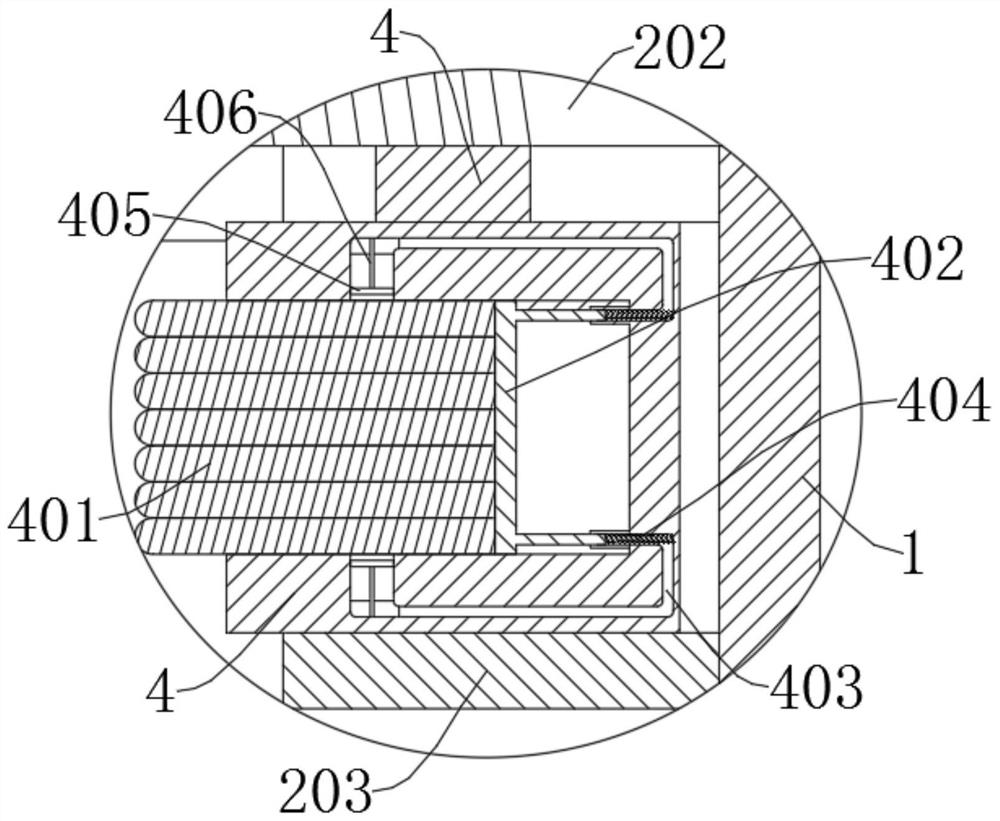

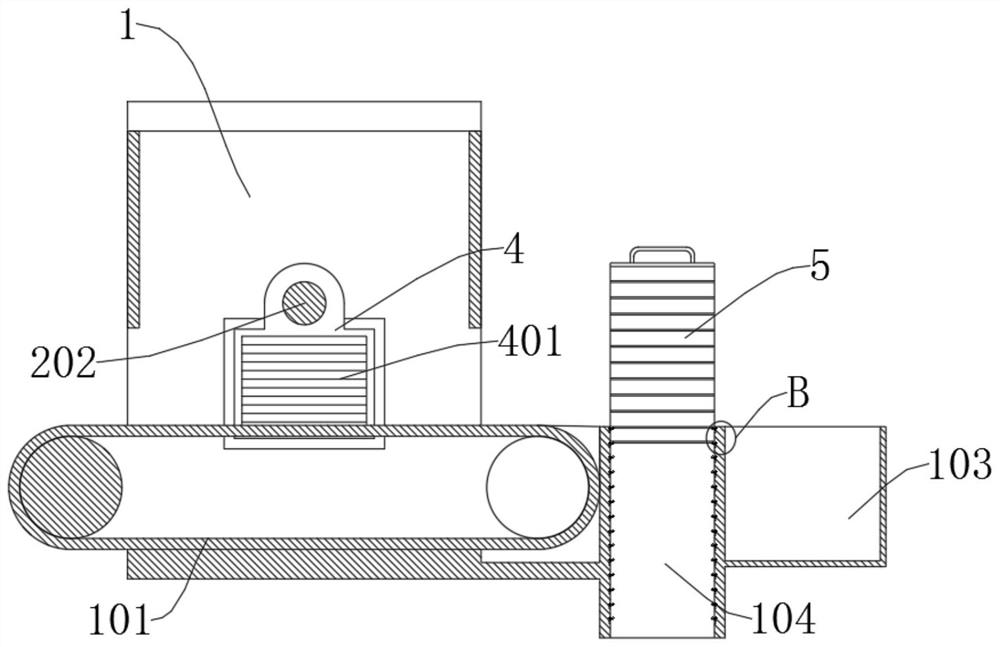

[0031] refer to Figure 1-8 , a kind of precision testing equipment and method of use of computer PCB mainboard, comprising: testing frame 1, the conveyor belt 101 that transports PCB main board is arranged on testing frame 1; Frame 4 is provided with two groups, which are respectively threaded on both sides of the forward and reverse screw rod 202, and the thread directions on the two clamping frames 4 are opposite, and the clamping frame 4 is used to clamp the PCB main board; the guide rail 203 is fixed Connected on the detection frame 1; wherein, the clamping frame 4 is slidably connected to the guide rail 203; the blanking chute 104 is arranged on the detection frame 1 and is located at one end of the conveyor belt 101; the collection frame 5 is slidably connected to the blanking chute 104 Inside; wherein, the collection rack 5 is provided with a collection plate 502 for placing the PCB main board, and the blanking chute 104 is rotatably connected with a rotating plate 504...

Embodiment 2

[0048] refer to Figure 1-8 , a precision testing device and method of use of a computer PCB main board, which are basically the same as in Embodiment 1. When the detected PCB main board needs to be collected, at this time, under the action of the conveyor belt 101, the detected PCB main board can be Transported to the collection plate 502, if the PCB main board is detected to be qualified, then the weight will not change, so that under the action of the collection plate 502, the PCB main board, and the collection frame 5's own gravity, the rotating plate 504 can be driven to rotate so that the collection frame 5 moves down. In order to collect the next qualified PCB main board;

[0049] If the PCB main board is unqualified, the weight will decrease, and the rotating plate 504 cannot be driven to rotate, even if the collecting rack 5 cannot move down, the unqualified PCB main board is positioned at the upper end of the collecting board 502, and the next PCB main board will pus...

Embodiment 3

[0052] refer to Figure 1-8 , a kind of precision testing equipment and method of use of computer PCB mainboard, comprising: testing frame 1, the conveyor belt 101 that transports PCB main board is arranged on testing frame 1; Frame 4 is provided with two groups, which are respectively threaded on both sides of the forward and reverse screw rod 202, and the thread directions on the two clamping frames 4 are opposite, and the clamping frame 4 is used to clamp the PCB main board; the guide rail 203 is fixed Connected on the detection frame 1; wherein, the clamping frame 4 is slidably connected to the guide rail 203; the blanking chute 104 is arranged on the detection frame 1 and is located at one end of the conveyor belt 101; the collection frame 5 is slidably connected to the blanking chute 104 Inside; wherein, the collection rack 5 is provided with a collection plate 502 for placing the PCB main board, and the blanking chute 104 is rotatably connected with a rotating plate 504...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com