A rubber sealing ring cutting machine

A technology of rubber sealing ring and cutting machine, applied in metal processing and other directions, can solve the problem of rubber ring easily sticking to the cutting device, etc., and achieve the effect of easy collection, uniform and efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

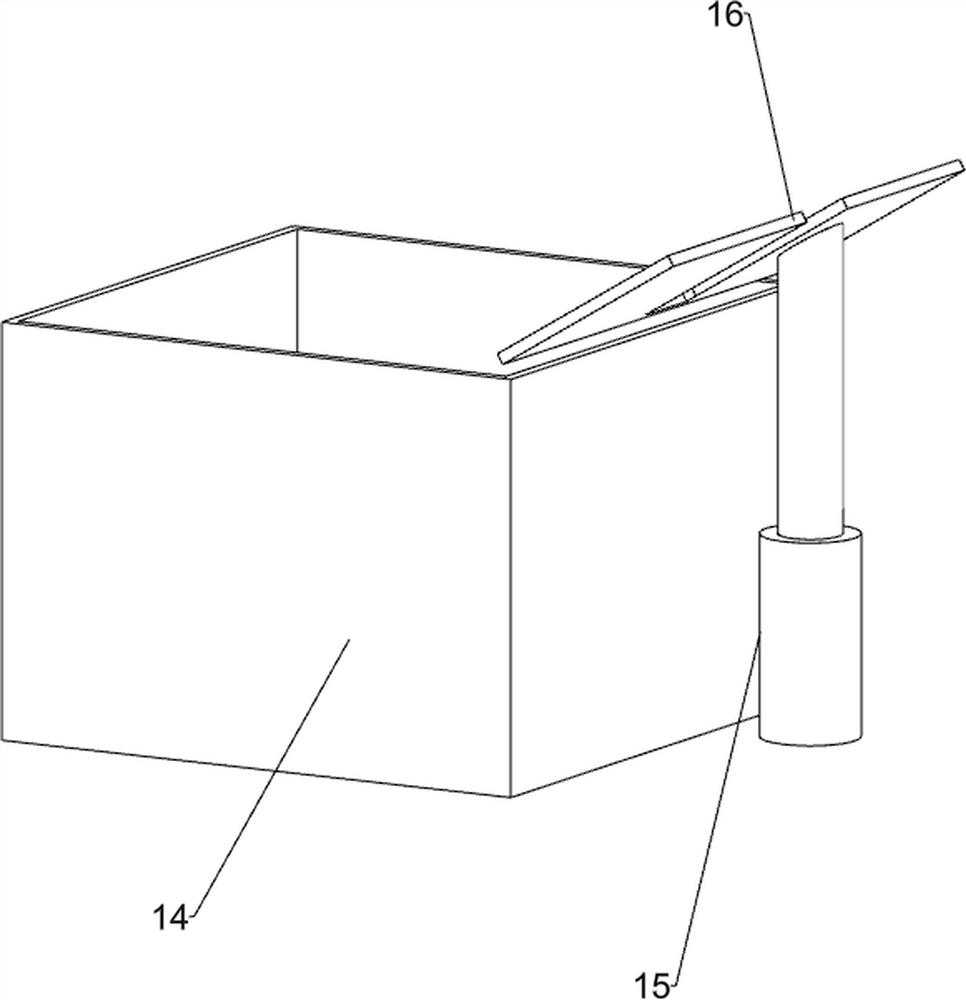

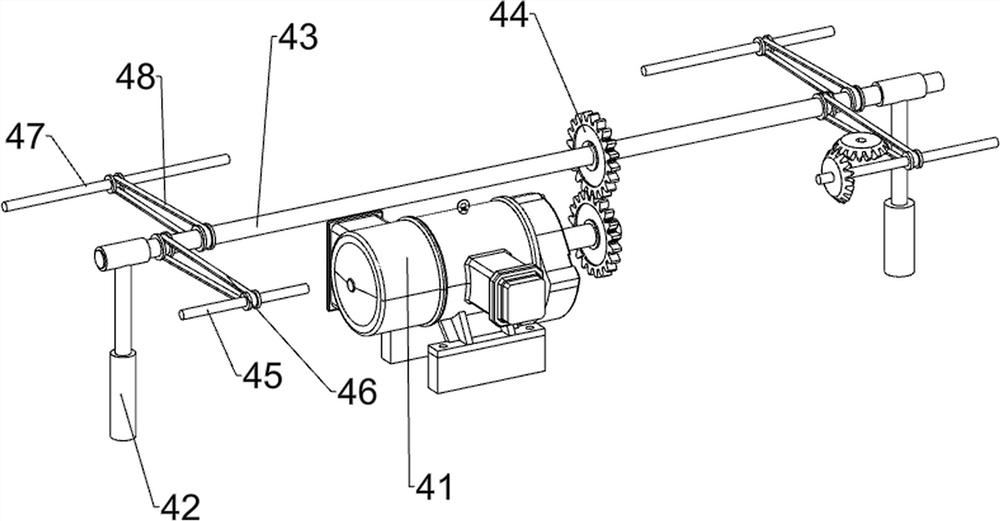

[0026] A rubber sealing ring cutting machine, such as Figure 1-5 As shown, it includes a bottom plate 1, a frame 2, a slideway 3, a transmission device 4, a clamping and feeding device 5 and a cutting device 6. The top of the bottom plate 1 is symmetrically provided with a frame 2, and the middle of the top of the bottom plate 1 is provided with a slideway 3. , The slideway 3 is located between the frame 2, the top of the bottom plate 1 is provided with a transmission device 4, the frame 2 is provided with a clamping and feeding device 5, and the frame 2 is provided with a cutting device 6.

[0027] When people need to use this machine, first people put the rubber ring on the slideway 3, then place the collection tool on the bottom plate 1 on the left side of the slideway 3, and then start the transmission device 4, so that the transmission device 4 drives the clip The tight feeding device 5 and the cutting device 6 operate, and the operation of the clamping feeding device 5 ...

Embodiment 2

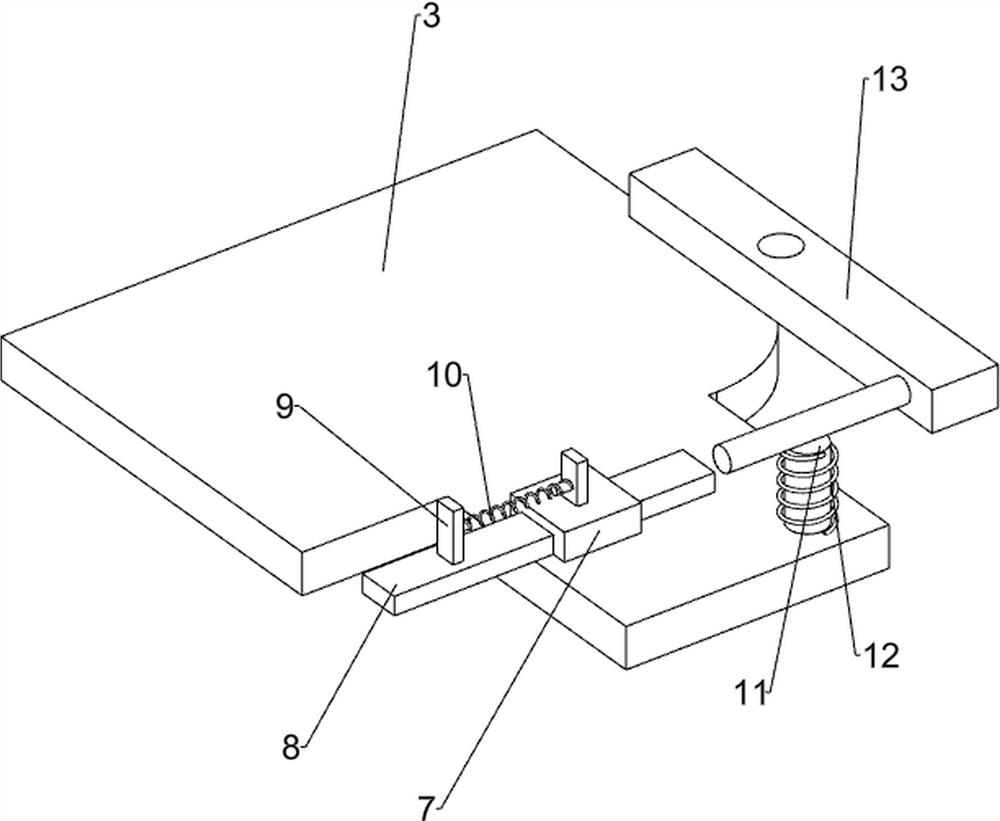

[0035] On the basis of Example 1, such as Figure 6-7 As shown, it also includes a guide block 7, a push plate 8, a fixed block 9, a second elastic member 10, a second connecting rod 11, a third elastic member 12 and a rotating block 13, and a guide block is provided on the left front side of the top of the slideway 3. 7. A push plate 8 is slidingly provided in the guide block 7, and a fixed block 9 is provided on the push plate 8 and the guide block 7, and a second elastic member 10 is arranged between the two fixed blocks 9, and the second elastic member 10 is a tension spring, the left front side of the top of the slideway 3 is provided with a second connecting rod 11, the second connecting rod 11 is covered with a third elastic member 12, and the third elastic member 12 is a torsion spring, and the second connecting rod 11 The upper rotation type is provided with a rotating block 13, the third elastic member 12 is connected with the rotating block 13 and the slideway 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com