Medicinal tube assembling machine

A tube group and straw technology, applied in the field of plastic processing, can solve the problems of different structures and functions at both ends, low processing efficiency, and inability to use directly, so as to improve the fault tolerance rate of equipment production, occupy less space and expand production scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

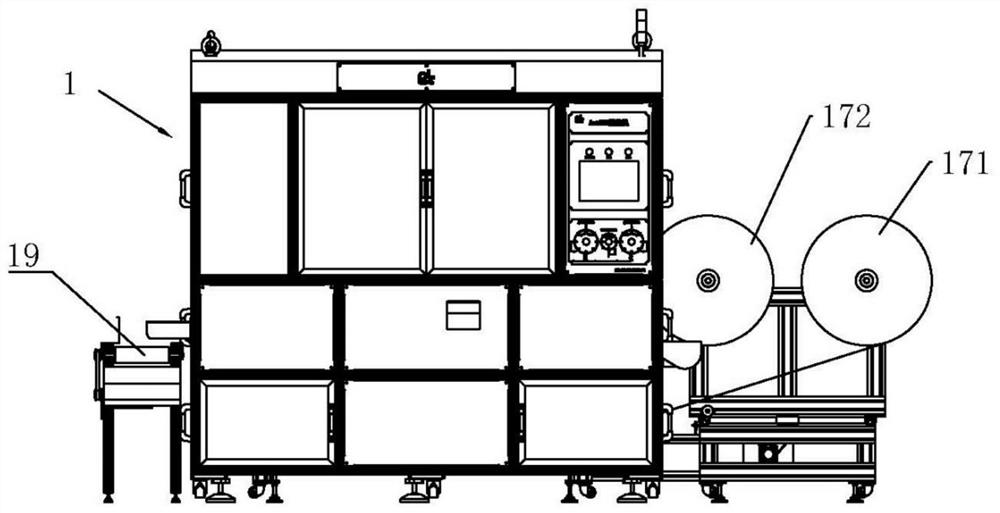

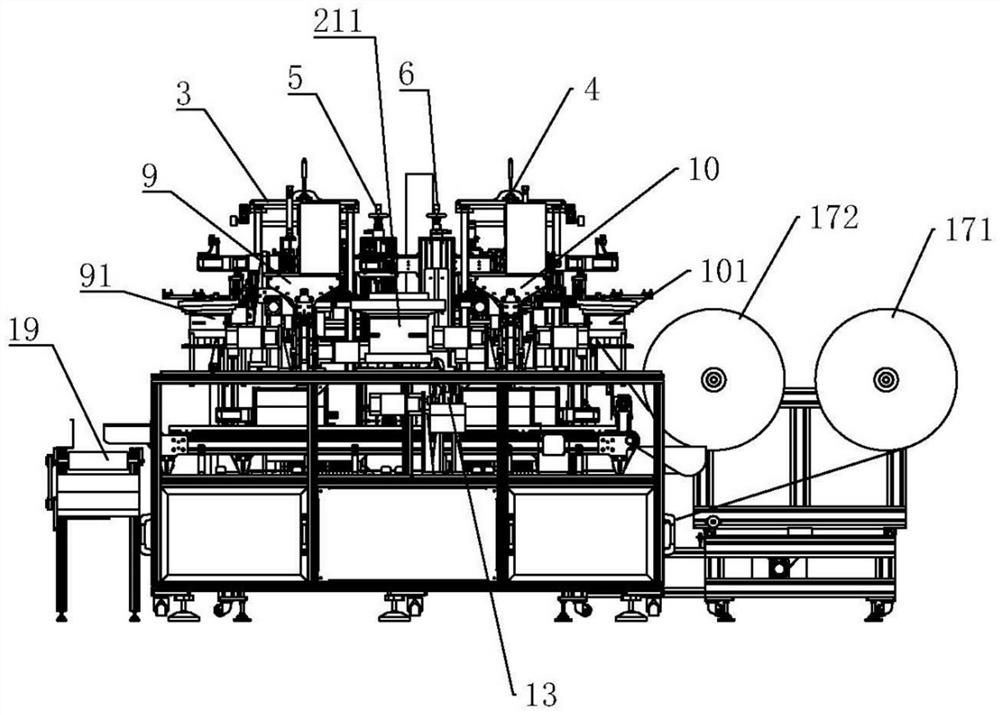

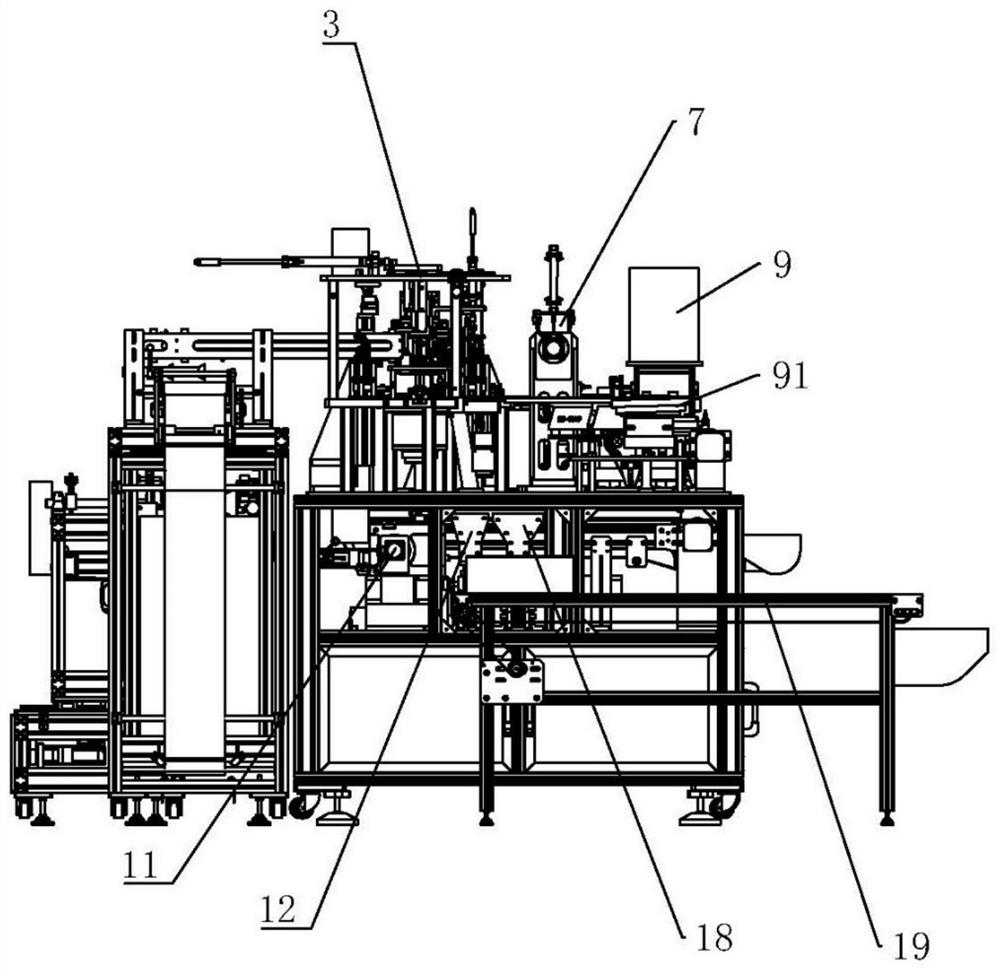

[0020] Such as figure 1 and figure 2 As shown, a medicinal tube assembly machine according to the preferred embodiment of the present invention includes a frame assembly 1, and the frame assembly 1 contains a material assembly layer, a material conveying layer and an electrical control layer sequentially from top to bottom. The material assembly layer includes an assembly platform 2, and the material delivery layer includes a delivery platform arranged under the assembly platform 2. The assembly platform 2 is provided with an assembly body for assembling various components, and the material delivery layer is used to deliver materials to the assembly body and output finished products. The electrical control layer includes an electrical cabinet arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com