CORC cable with transposed close layers

A cable and similar technology, applied in the field of CORC cables, can solve the problems of inductance parameter difference between layers, uneven current distribution, etc., to improve the degree of strip transposition, improve the difference of inductance parameters between layers, and improve the uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

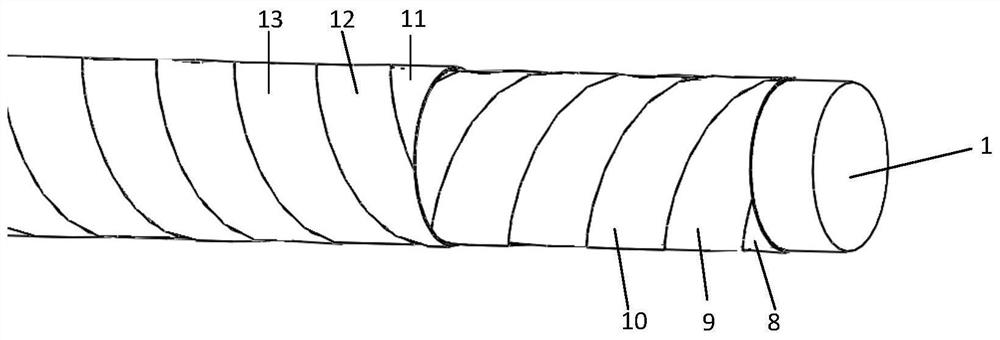

[0015] Such as figure 1 As shown, a conventional CORC cable includes a central skeleton 1, superconducting tapes 8, 9, 10, 11, 12, 13;

[0016] The skeleton 1 includes but is not limited to copper pipes and stainless steel pipes, and appropriate materials can be selected according to the requirements of the cable to be wound.

[0017] The superconducting strips 8, 9, 10 are wound forward on the central skeleton, as the first layer of superconducting strips of the CORC cable;

[0018] The superconducting strips 11, 12, 13 are reversely wound on the central frame, as the second layer of superconducting strips of the CORC cable;

[0019] The winding angles of the superconducting strips 8, 9, 10 and the superconducting strips 11, 12, 13 are symmetrical along the axial direction of the cable, and the angle between the strips and the axial direction of the cable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com