Winding device for plastic pad packaging

A technology of winding device and plastic mat, which is applied in the direction of transportation and packaging, winding strips, and thin material processing, etc., and can solve the problems of unable to transport plastic mats, cutting plastic mats, and low efficiency of plastic mat winding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

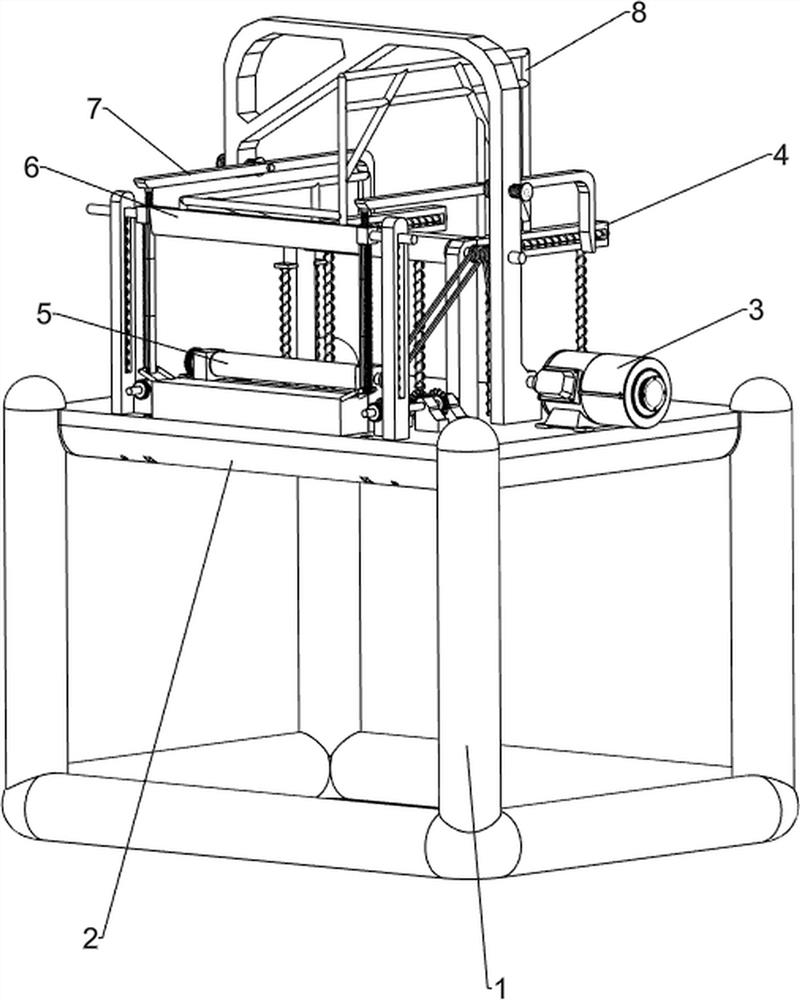

[0068] A winding device for plastic cushion packaging, such as figure 1 As shown, it includes a bottom frame 1, a molding plate 2, a winding mechanism 3 and a pressing mechanism 4. The top of the bottom frame 1 is provided with a molding plate 2, and the top of the molding plate 2 is equipped with a winding mechanism 3, and the molding plate A pressing mechanism 4 is slidably provided between the rear side of the 2 and the rear side of the winding mechanism 3 .

[0069] When a worker needs to rewind the plastic pad, the worker needs to wind one end of the plastic pad around the winding mechanism 3, and then the worker needs to start the winding mechanism 3 to rotate, and the rotation of the winding mechanism 3 can rewind the plastic pad Work, when the rewinding mechanism 3 rolls up the plastic pad to a certain thickness, the hold-down mechanism 4 is compressed, and when the hold-down mechanism 4 resets, the hold-down mechanism 4 will compress the plastic pad on the rewind mech...

Embodiment 2

[0071] In a preferred embodiment of the present invention, as figure 2 As shown, the winding mechanism 3 includes a motor 31, a first transmission shaft 32, a fixed column 33, a reel 34 and a first pulley assembly 35, the right side of the top of the profile plate 2 is fixed with a motor 31 by bolts, and the output of the motor 31 The shaft is provided with a first transmission shaft 32, and a fixed post 33 is installed on the right side of the top of the profile plate 2, and a spool 34 is rotatably connected between the top of the fixed post 33 and the top left side of the profile plate 2, and the right end of the spool 34 is connected to the first A first pulley assembly 35 is connected between the transmission shafts 32 .

[0072] The worker first needs to wrap the end of the plastic pad around the fixed column 33, and then the worker starts the motor 31 to rotate, and the rotation of the motor 31 through the output shaft will drive the first transmission shaft 32 to rotat...

Embodiment 3

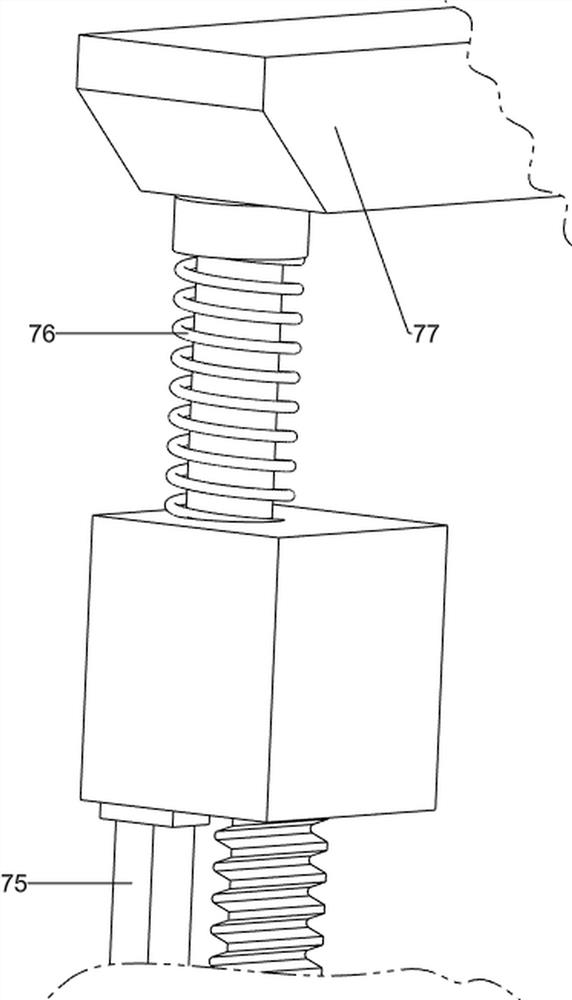

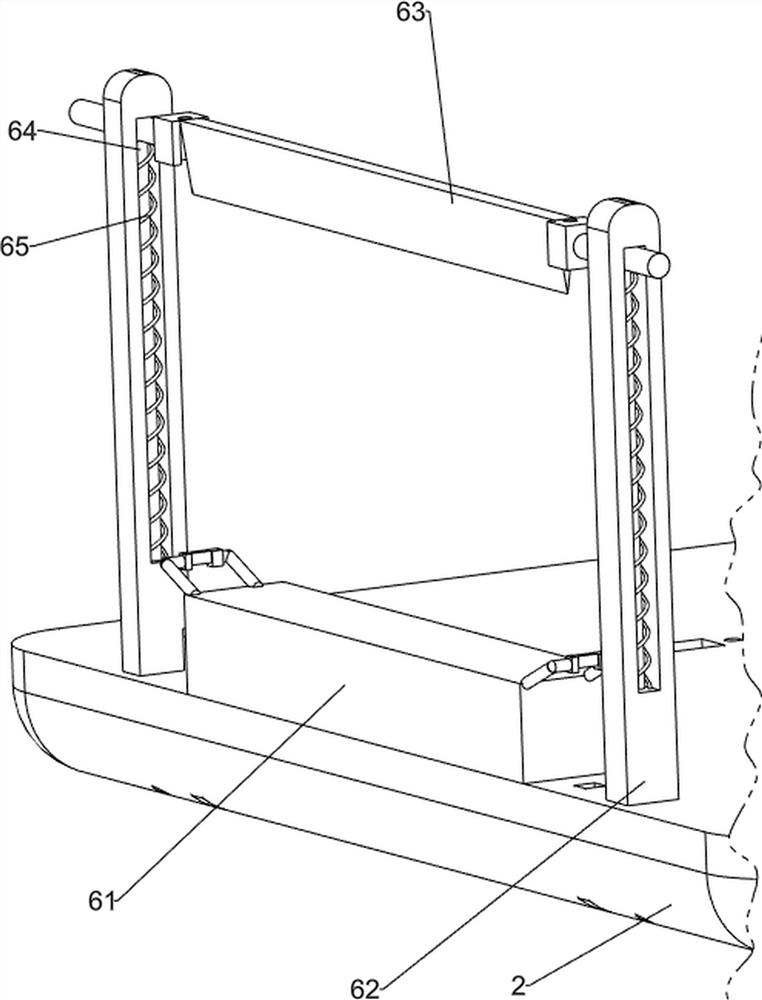

[0074] In a preferred embodiment of the present invention, as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, the pressing mechanism 4 includes a first limit frame 41, a fastening column 42, a first extension rod 43 and a first telescopic spring 44, and the rear side of the fixed column 33 and the rear side of the left part of the positioning plate 2 are all provided with There is a first limit frame 41, the first limit frame 41 slides on the fixed column 33, and a fastening column 42 is slid between the two first limit frames 41, and the first limit frame 41 is sliding A first extension rod 43 is provided, the front end of the first extension rod 43 is connected with the fastening column 42, the first extension rod 43 is covered with a first telescopic spring 44, and the two ends of the first telescopic spring 44 are respectively connected to the first limit On the bit frame 41 and the fastening post 42.

[0075]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com