Washing machine drainage control method and washing machine

A control method and washing machine technology, applied to the control device of the washing machine, washing device, textile and paper making, etc., can solve the problems of cost increase, large depth difference between the inner bucket and the water tray, drainage overflow, etc., and reduce the total drainage time , Improve the drainage efficiency and speed up the drainage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

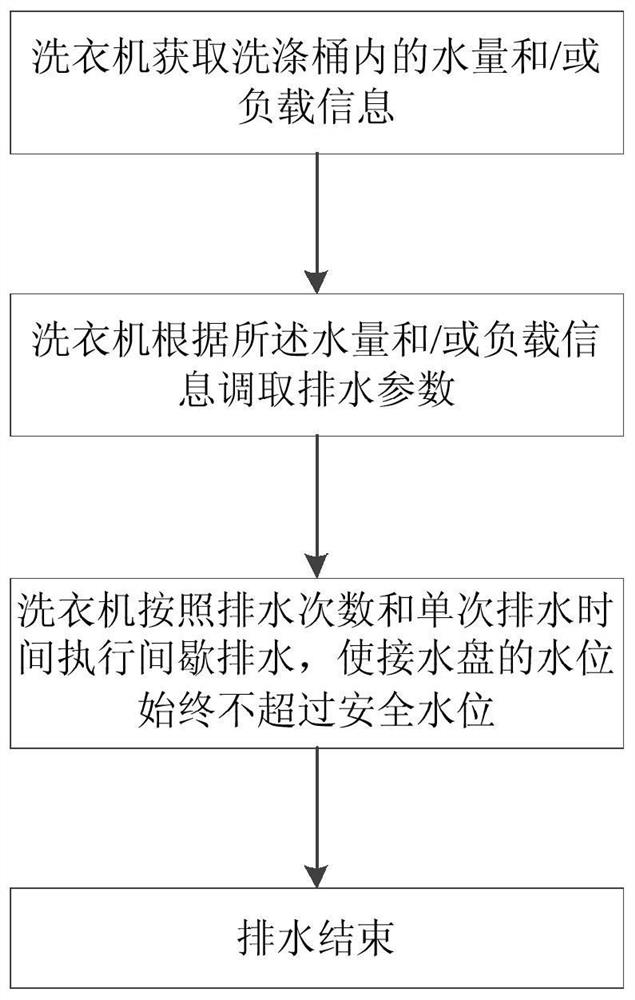

[0044] In this embodiment, a method for controlling drainage of a washing machine is provided. The washing machine includes a washing tub and a water tray connected to the drain outlet of the washing tub. The washing machine controls the drainage process according to the water volume and / or load information in the washing tub, so that the washing tub The water is always lower than the safe water level of the drip tray.

[0045] In this embodiment, the depth of the water receiving tray of the washing machine is shallower than that of the washing tub, so if the drain port is kept open during the drainage process, the drain may overflow the water receiving tray. In the drainage control method provided by the present invention, the washing machine detects and records the load information of the clothes put into the washing tub, the load information of the clothes includes weight and material, and records the water inflow during washing and rinsing, and integrates the load informati...

Embodiment 2

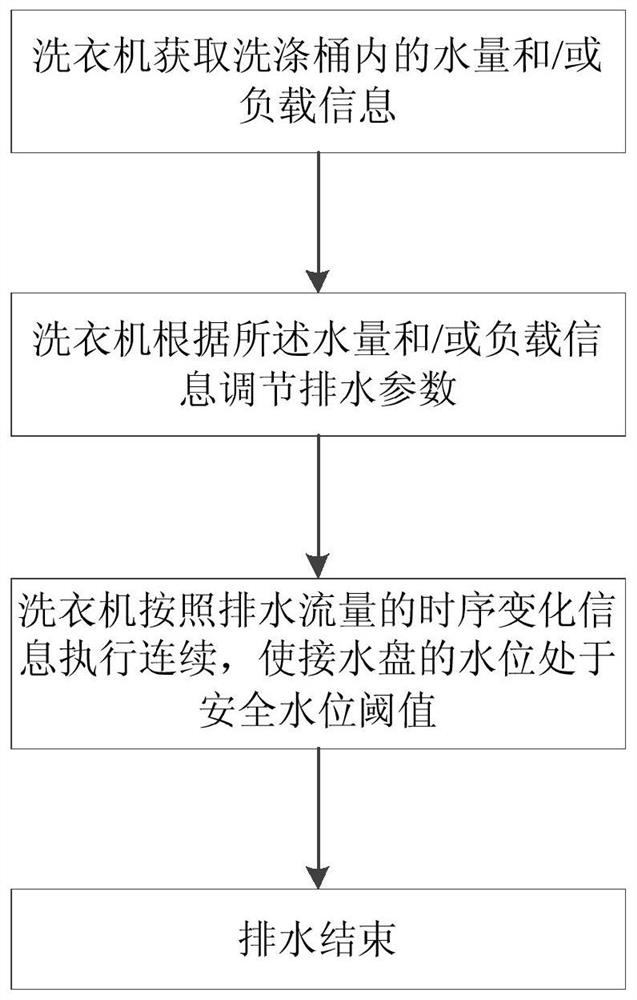

[0059] The difference between this embodiment and embodiment 1 is:

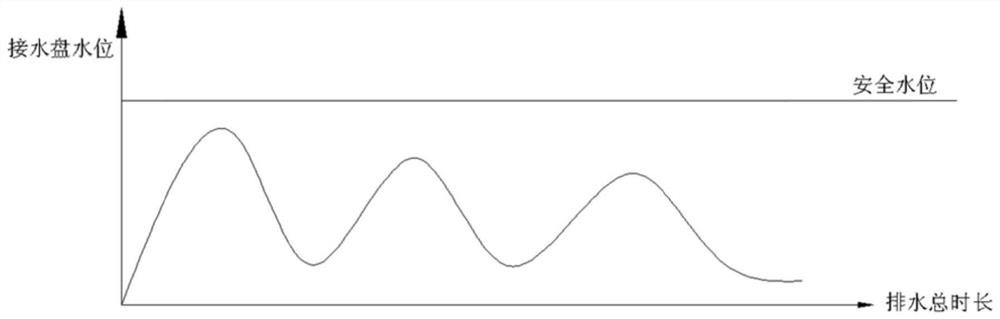

[0060] In this embodiment, the washing machine continuously discharges the water in the washing tub into the water receiving tray.

[0061] In this embodiment, due to the shallow depth of the water receiving tray, in order to prevent the water receiving tray from overflowing, the washing machine controls and adjusts the drainage process, which will cause the total drainage time to become longer. On the premise of water overflow, a continuous drainage solution is provided, and the continuous drainage is realized by adjusting the drainage flow within the total drainage time.

[0062] In this embodiment, the washing machine controls the opening of the drain port during the continuous draining process.

[0063] In this embodiment, the water receiving tray is connected with a normally open drain pipe 21 that drains the water out, and the washing bucket communicates with the water receiving tray through the drain ...

Embodiment 3

[0073] In this embodiment, a washing machine is provided, comprising a washing tub 1 and a water receiving tray 2 communicating with the washing tub drain 11. The depth of the water receiving tray 2 is shallower than that of the washing tub 1, and the washing machine adopts the drainage method of Embodiment 1 or 2. The control method is to adjust the drainage parameters according to the water volume and / or load information in the washing tub 1 so that the water discharged from the washing tub 1 is always lower than the overflow water level of the water receiving tray 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com