Stage constant-speed ascending and descending device and control method thereof

A lifting device and stage technology, which is applied in the field of stage lifting, can solve the problems of large thickness of the supporting surface of the stage, no guardrails, and restrictions on the use of the stage, and achieve the effects of increasing applicability, ensuring safety, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

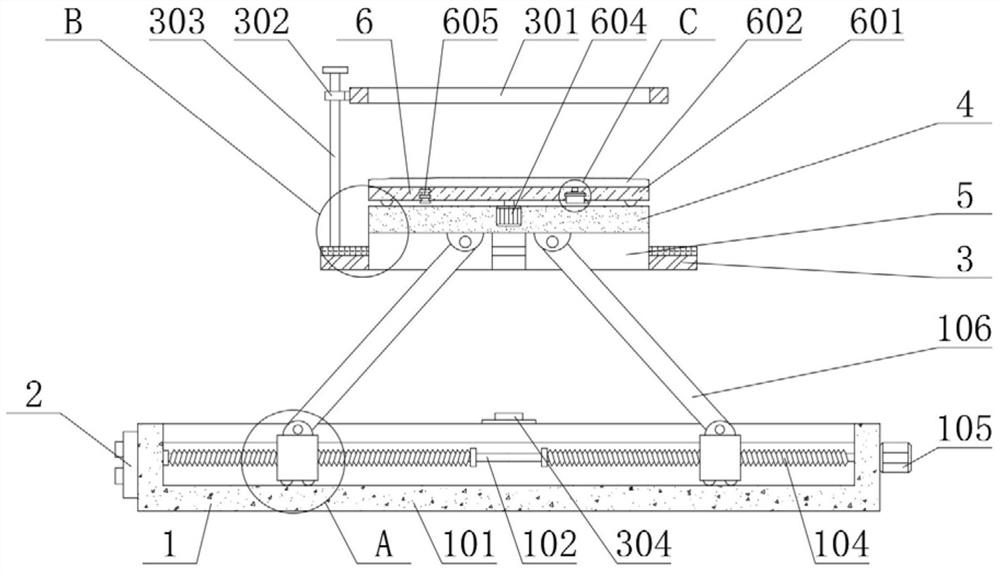

[0029] see Figure 1-6 , the present invention provides a technical solution:

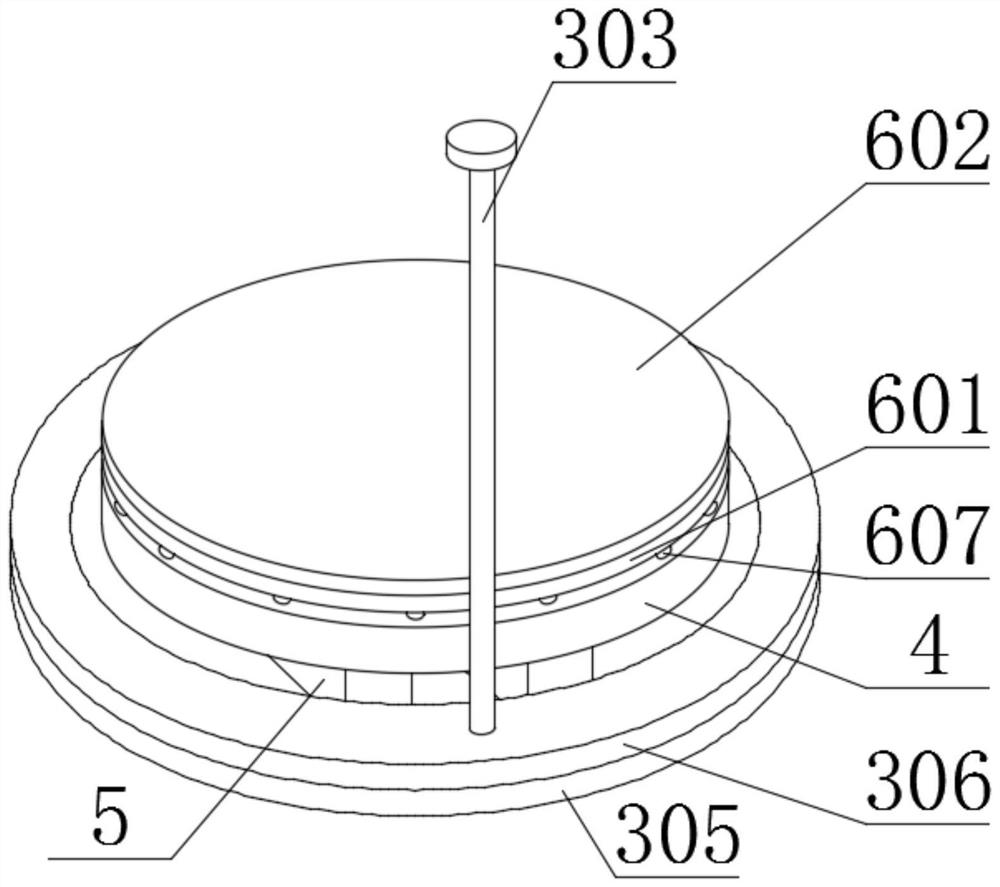

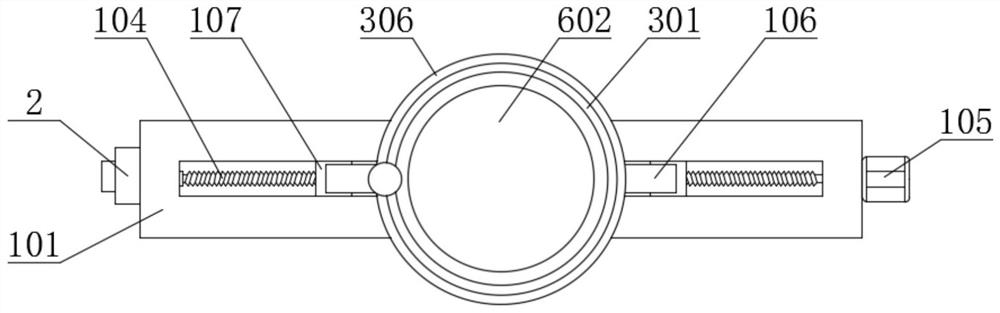

[0030] The stage uniform lifting device includes a support plate 4 and a controller 2. The bottom end of the support plate 4 is provided with a lifting mechanism 1, and the bottom end of the support plate 4 is fixedly connected with a limit plate 5, which acts as a limit. , the lifting mechanism 1 includes a support surface 101, the right end of the support surface 101 is fixedly connected with a first motor 105, the end of the main shaft of the first motor 105 is fixedly connected with a rotating rod 102, and the left and right sides of the rotating rod 102 are fixedly connected with threads 104, The directions of the threads 104 on the left and right sides are opposite, and the outer sides of the threads 104 are spirally connected with a slide block 107, and the top of the slide block 107 is connected with a connecting rod 106 through a hinge, and the top of the connecting rod 106 and the bottom ...

Embodiment 2

[0034] Workflow: In Embodiment 2, the same parts as Embodiment 1 will not be repeated. The difference is that when the performers feel that the inflatable air cushion 602 is hard and will affect their performance, they can control the solenoid valve 605 to open through the controller 2. The electromagnetic valve 605 is opened, and the air inside the inflatable air cushion 602 will be discharged, and the top surface of the inflatable air cushion 602 will become soft due to the reduction of internal pressure, so as to meet the needs of performers, and has good practicability. The controller 2 controls the motor 105 to reverse, the motor 105 drives the rotating rod 102 to rotate, and the rotating rod 102 drives the threads 104 on both sides to rotate, because the directions of the threads 104 on both sides of the rotating rod 102 are opposite, and the threads 104 on both sides will respectively drive The slide block 107 on the outside is separated, and during the process of separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com