Winding equipment for transformer production

A technology of winding equipment and transformers, applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., to achieve the effect of winding position and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

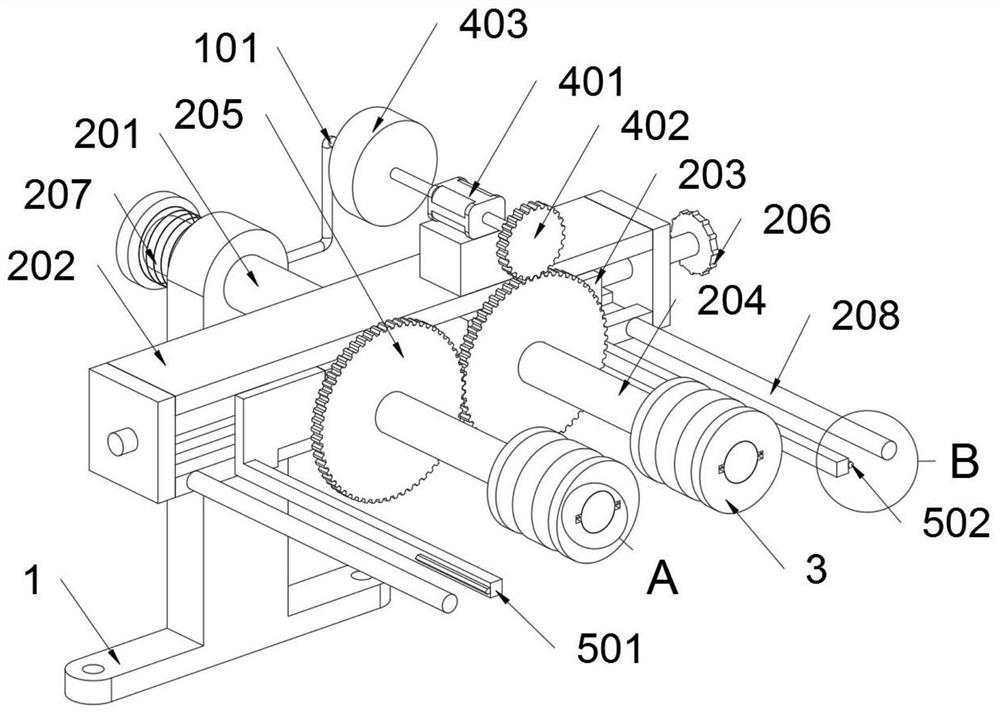

[0034] as attached figure 1 to attach Figure 8 Shown:

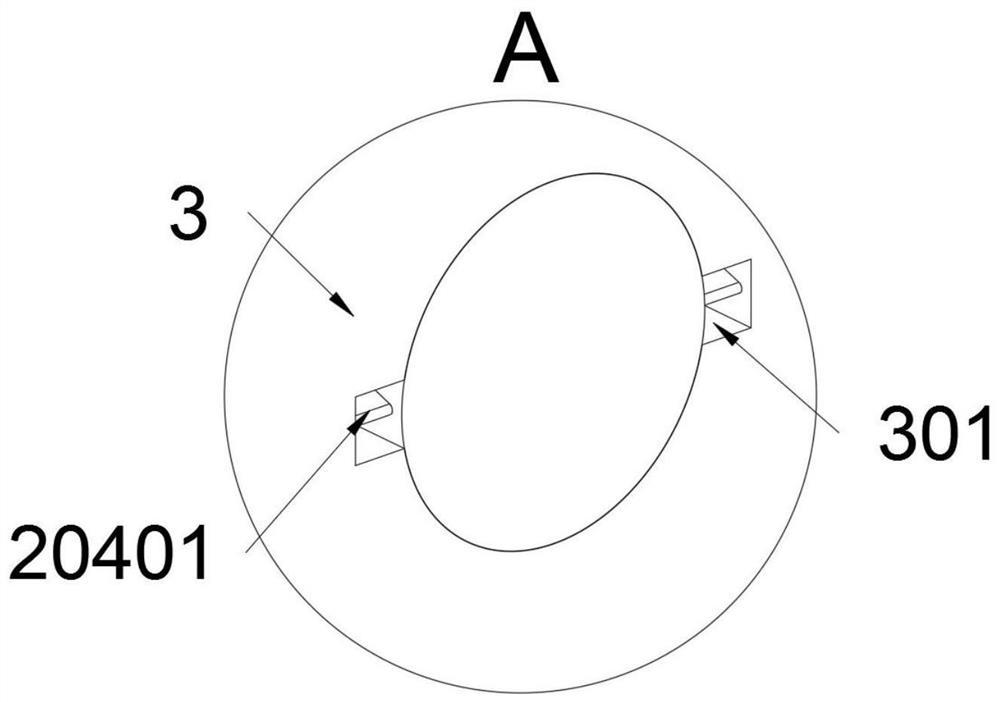

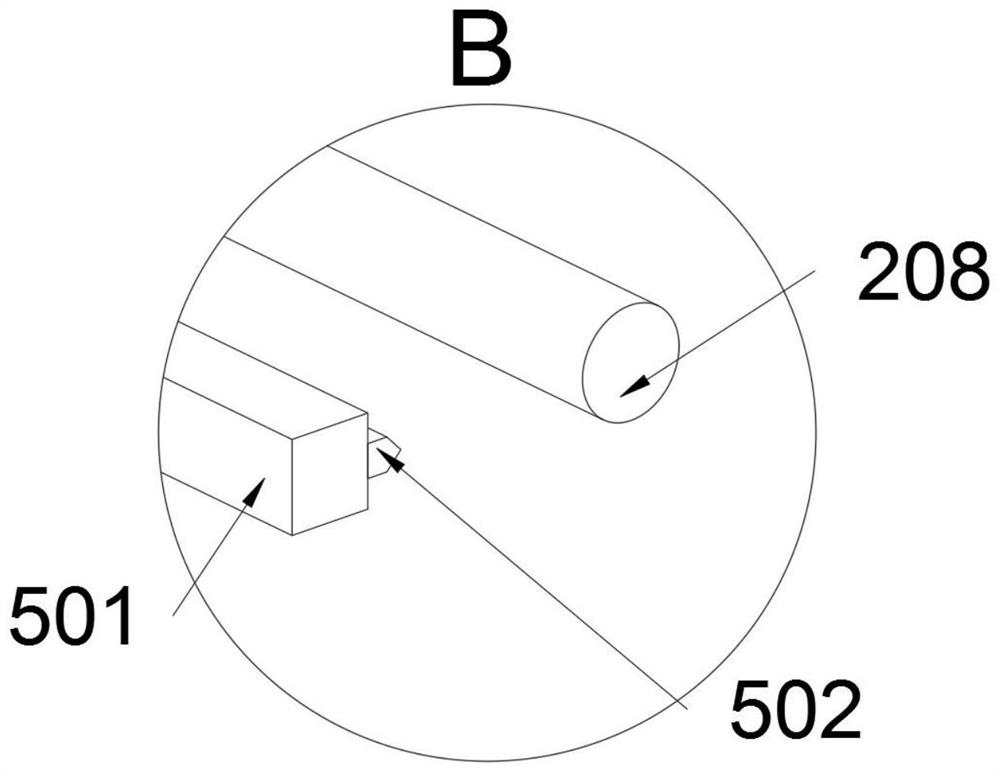

[0035] The invention provides a winding device based on transformer production, which includes a frame body 1; a winding structure 2 is installed on the frame body 1, and a winding seat 3 is installed on the winding structure 2; a drive is installed on the winding structure 2 structure 4, and a cutting structure 5 is also installed on the winding structure 2; refer to as figure 1, the frame body 1 includes a toggle lever 101, and a toggle lever 101 is welded on the frame body 1; the drive structure 4 includes a force seat 403, the force seat 403 is installed on the rotating shaft of the drive motor 401, and the force seat 403 It is in contact with the toggle rod 101, and the rear end surface of the force seat 403 is an inclined structure. When the driving motor 401 rotates, the main body rod 201 is in a reciprocating state under the toggle of the toggle rod 101, thereby realizing the transformation of the winding posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com