High-temperature electric tracing band

A technology of electric heating cable and high temperature, which is applied in the direction of ohmic resistance heating parts, heating elements, heating element shape, etc., which can solve problems such as damage, waste of time, and affect the normal use of electric heating cable, so as to ensure normal use and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

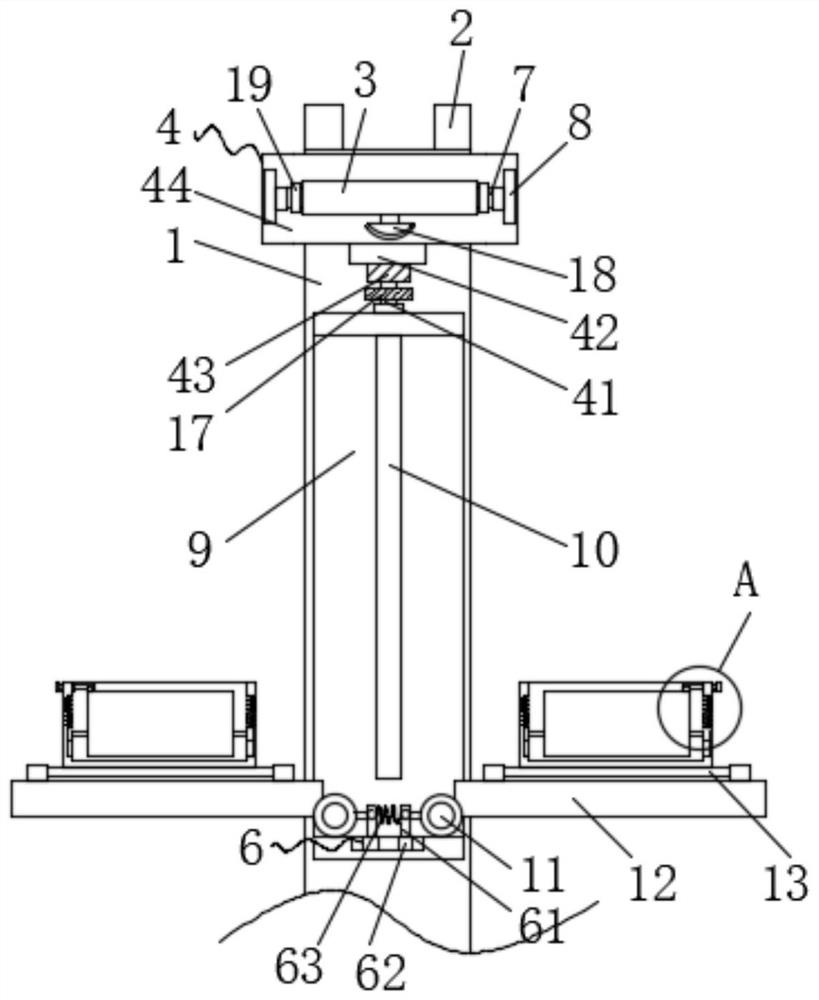

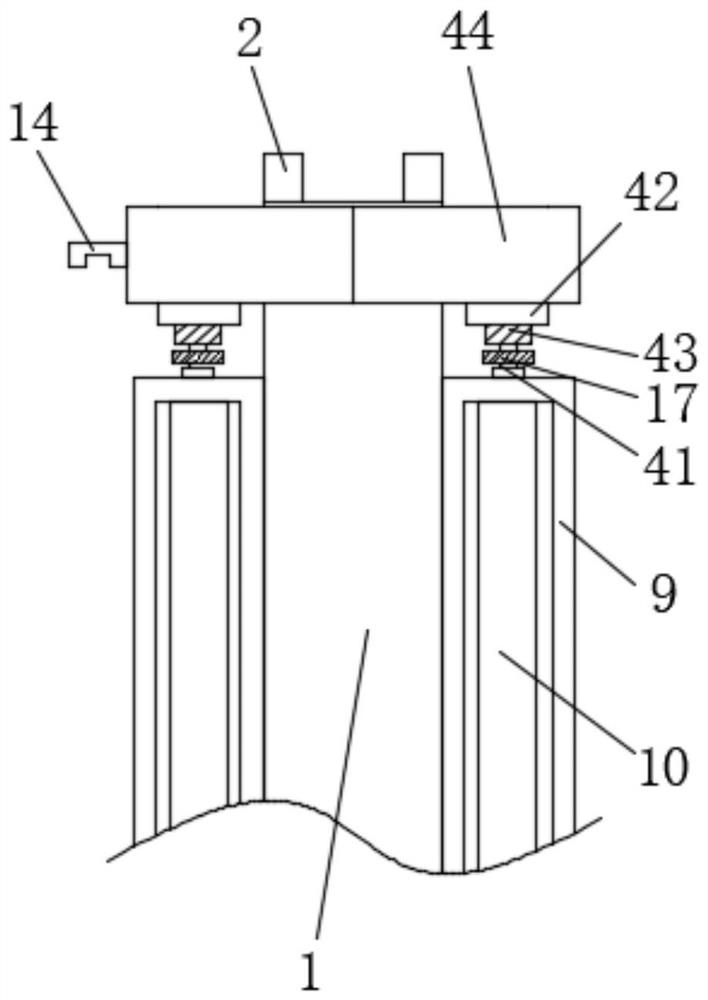

[0026] Such as Figure 1-3 As shown, the present invention provides a high-temperature electric heating cable, including an electric heating cable body 1, one end of the electric heating cable body 1 is provided with a metal contact 2, and the front and back of the electric heating cable body 1 are fixedly connected with installation Shell 9, the left and right sides of the installation shell 9 are provided with first through holes, the upper surface of the installation shell 9 is clamped with the protection mechanism 4, and the lower surface of the inner wall of the installation shell 9 is clamped with two fourth bearings, the fourth bearing The inner sleeve is provided with a fourth rotating shaft 11, the outer surface of the fourth rotating shaft 11 is fixedly connected to the limiting plate 12, the upper surface of the limiting plate 12 is clamped with two fifth bearings, and the inner sleeve of the fifth bearing is provided with a fifth rotating shaft 13 , the upper surfa...

Embodiment 2

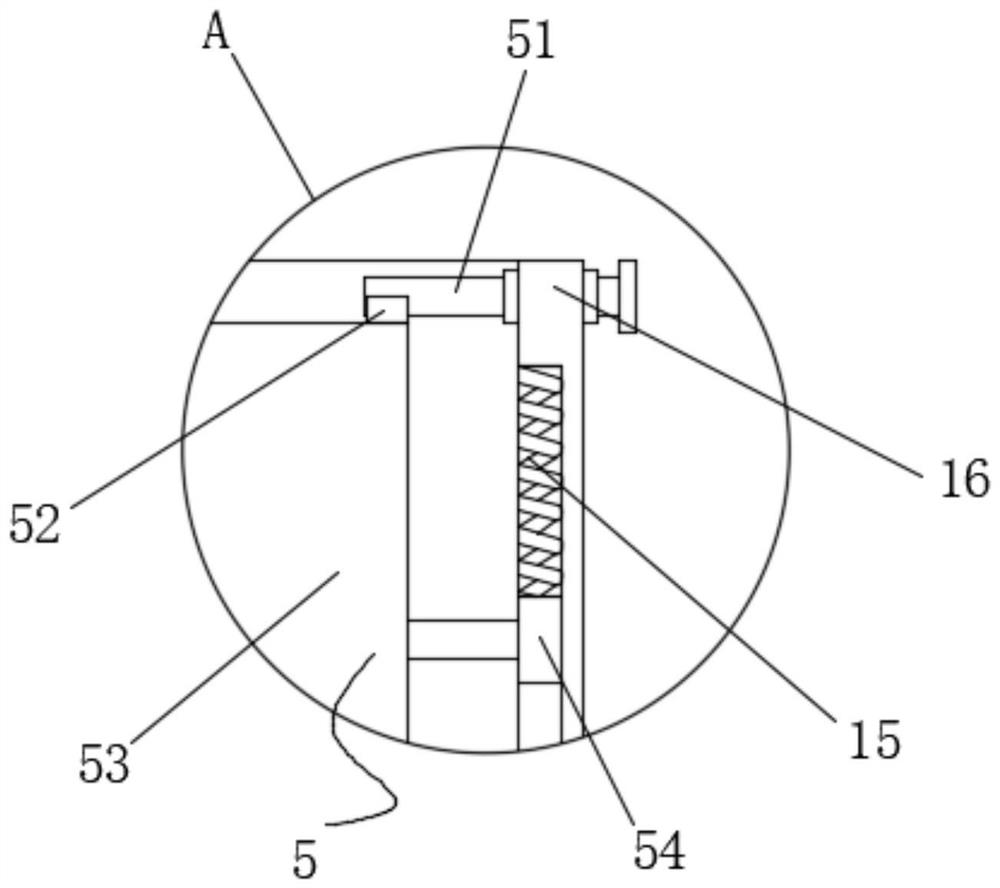

[0029] This embodiment provides a high-temperature electric heating cable, which differs from Embodiment 1 in that, as image 3 As shown, the extension mechanism 5 includes a second rotating shaft 51, a stopper 52 and an extension plate 53. The left and right sides of the inner wall of the heat conduction cover 16 are provided with a first chute, and the first chute is slidably connected with a first chute. Block 54, one side of the first sliding block 54 is fixedly connected with an extension plate 53 through an extension rod, the upper surface of the extension plate 53 fits with the block 52, and the block 52 is fixedly connected with the outer surface of the second rotating shaft 51, the second The rotating shaft 51 is sheathed in the second bearing that is clamped on one side of the heat conduction cover 16 , and one end of the second rotating shaft 51 is fixedly connected with a handle.

[0030] In practical applications, when it is necessary to further increase the snowm...

Embodiment 3

[0032] This embodiment provides a high-temperature electric heating cable, which differs from Embodiment 2 in that, as Figure 1-3 As shown, the limit mechanism 6 includes an insertion rod 61 and a first spring 63, two insertion rods 61 are arranged on the lower surface of the inner wall of the installation shell 9, and the other end of the insertion rod 61 is inserted on a side of the fourth rotating shaft 11 and opened. In the limit groove of the slit, the front of the insertion rod 61 is fixedly connected with a pressure rod, and the pressure rod passes through the second through hole opened on the front of the installation shell 9 and extends to the outside of the installation shell 9, and the two insertion rods 61 are fixed by the first spring 63 connect.

[0033] In practical applications, when it is necessary to initially increase the snow melting area, move the two pressure blocks closer to the middle and squeeze the first spring 63, so that the insertion rod 61 moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com