Method and system for monitoring machining tool condition

A machining and cutting tool technology, applied in the field of machining tool status monitoring, can solve problems such as increasing the burden on the system, reducing the flexibility of the tool status monitoring system, and monitoring models that cannot meet the requirements, so as to reduce training time and efficiency and improve adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0058] Embodiments of the present invention provide a method and system for monitoring machining tool status, applying the transfer learning method to the machining tool status monitoring system, and making full use of the accumulated source domain data and monitoring model that have been accumulated before the application scenario changes, By extracting the available information and combining as little new sample data (target domain data) as possible, a model suitable for the changed scene can be obtained quickly and efficiently.

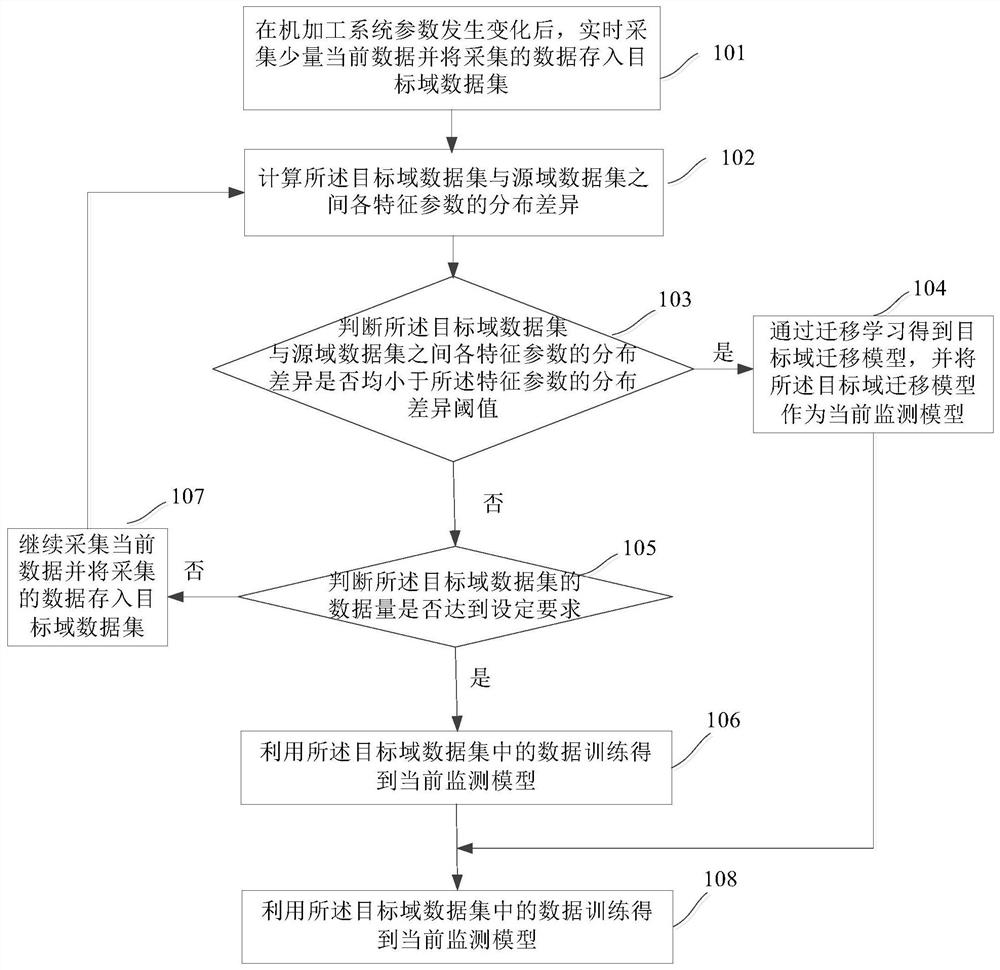

[0059] like figure 1 As shown, it is a flow chart of the method for monitoring the state of machining tools according to the embodiment of the present invention, which include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com