Active extension type automobile front bumper

A front bumper and extension technology, which is applied in the field of active extension car front bumper, can solve the problems of personal injury in the car, weak ability to resist impact, short buffer distance, etc., so as to improve driving safety and reduce body damage , Increase the effect of the buffer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

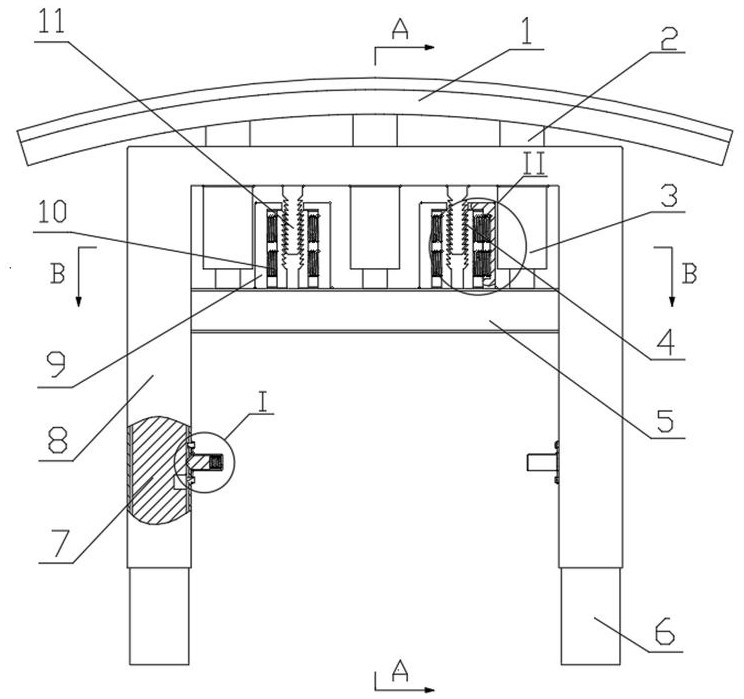

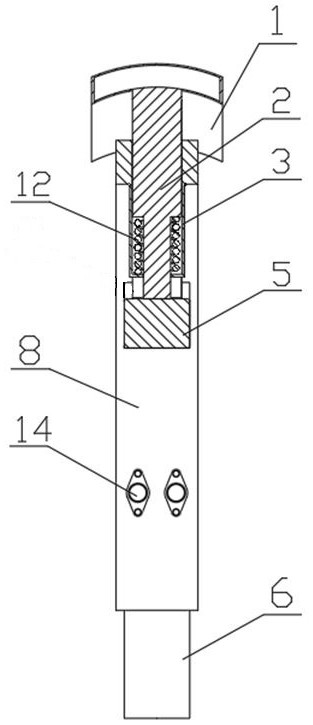

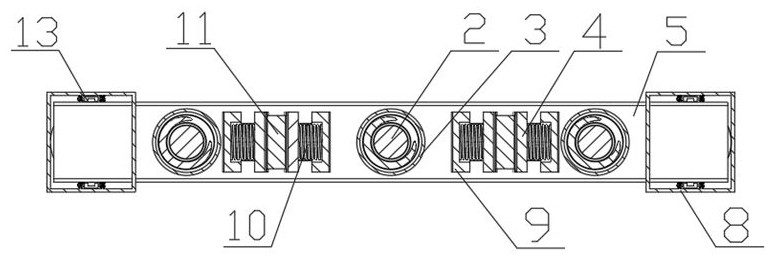

[0015] In order to facilitate the understanding of the layout orientation, the driving direction of the vehicle is now defined as "front", and the opposite direction is "rear"; figure 1 The bumper 1 is in the front, and the movable beam 5 is behind; the bumper 1 is left and right symmetrical, relative to the central axis of the bumper 1, when moving in the left and right direction, the central axis close to the bumper 1 is "inside", otherwise it is "inner". outside".

[0016] Such as figure 1 As shown, a U-shaped fixed vehicle frame 8 is provided directly behind the bumper 1, and the U-shaped fixed vehicle frame 8 is fixed and symmetrically arranged. The U-shaped opening of the U-shaped fixed vehicle frame 8 is towards the rear, and is composed of a crossbeam on the front side and a longitudinal beam on the left and right. The crossbeam and the longitudinal beam are all rectangular plates. The cross beam is a solid beam arranged along the left and right directions, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com