Curtain self-cutting Roman hole forming device for cloth processing

A technology for curtains and horse holes is applied in the field of self-cutting Roman hole devices for fabric processing curtains, which can solve the problems of cumbersome process and easy error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

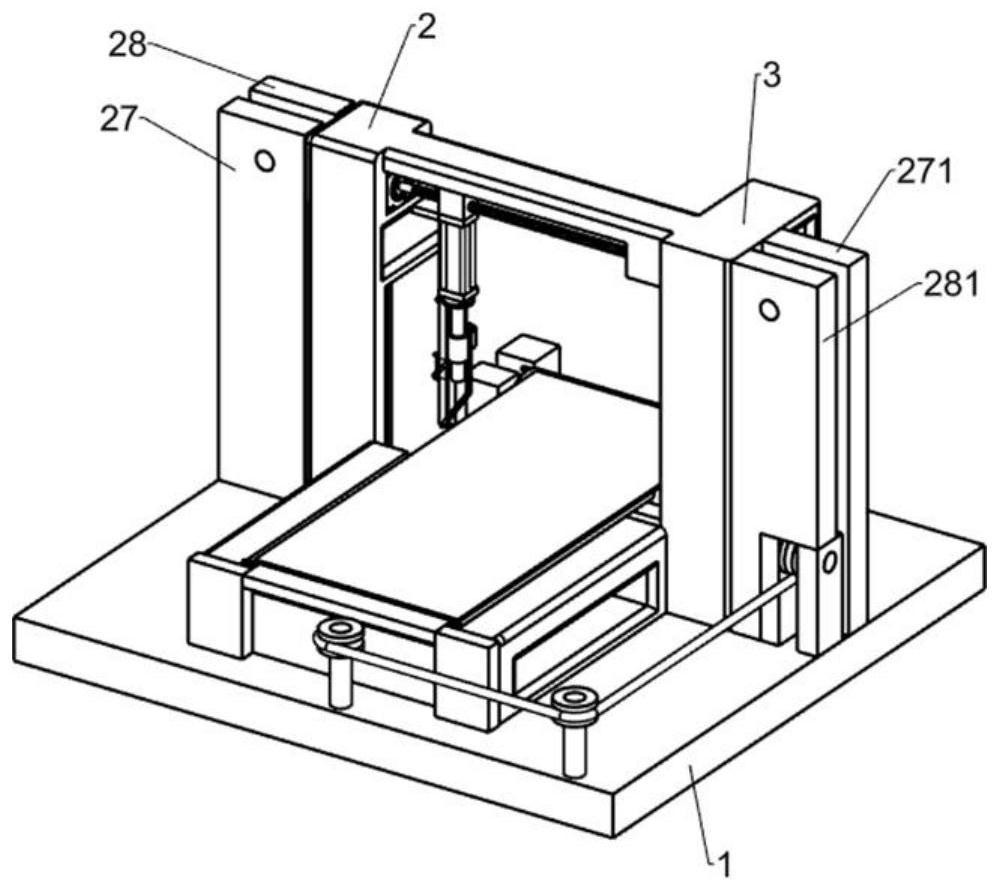

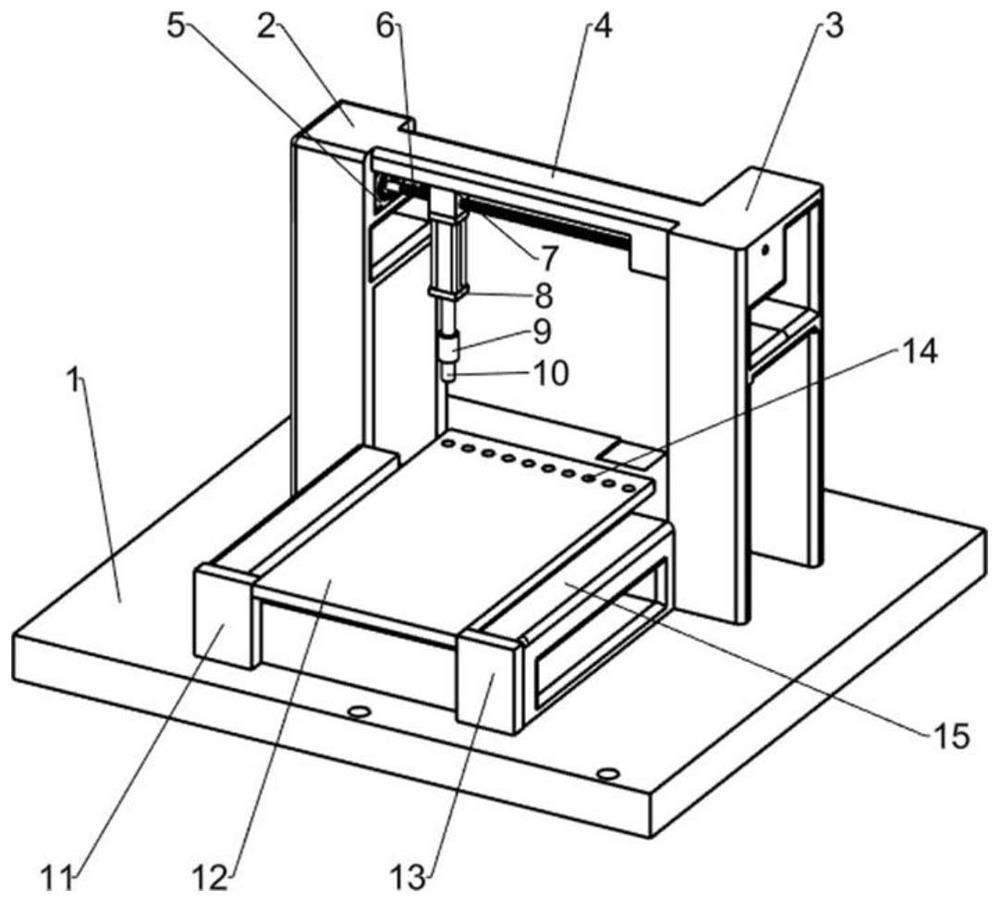

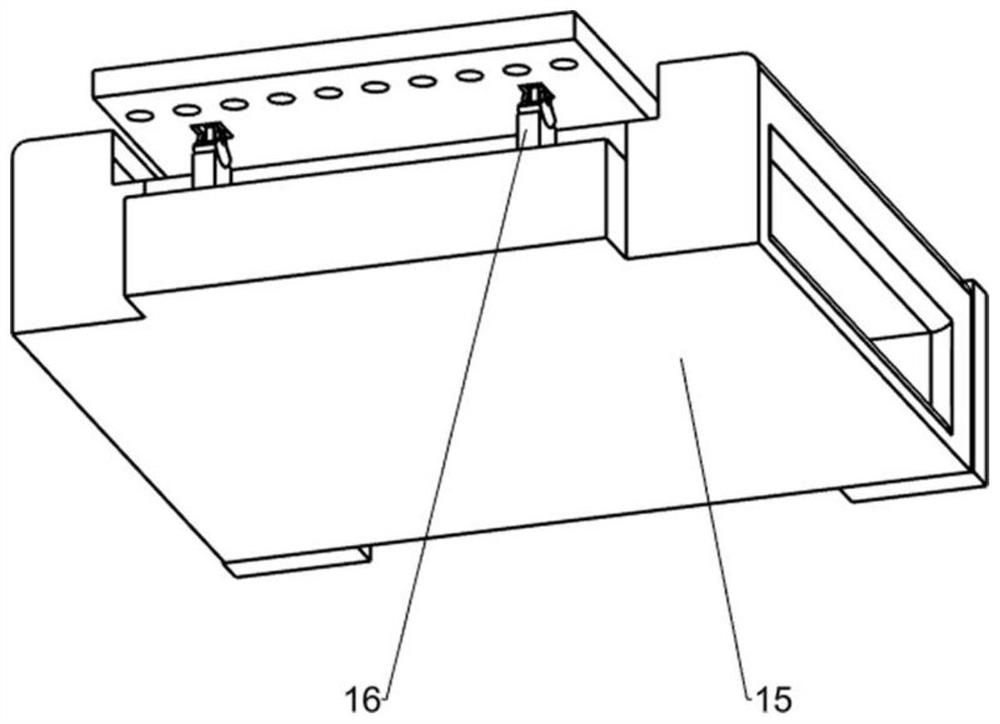

[0044] A curtain self-cutting open Roman hole device for fabric processing, such as Figure 1-16 As shown, it includes an equipment base 1, a stamped first support frame 2, a stamped second support frame 3, a reciprocating stamping mechanism, a first rectangular support seat 11, a second rectangular support seat 13, a blind hole plate 12, and a hollow support frame 15 , a cloth roll mechanism, a cloth pulling mechanism and a passable hinge, the upper side of the rear of the equipment base 1 is symmetrically fixedly connected with a stamped first support frame 2 and a stamped second support frame 3, and the upper side of the stamped first support frame 2 is provided There are rectangular holes, and a reciprocating stamping mechanism is arranged on the middle upper side of the stamped first support frame 2 and the stamped second support frame 3, and the upper side of the front part of the equipment base 1 is symmetrically fixedly connected with the first rectangular support seat ...

Embodiment 2

[0047] On the basis of embodiment 1, a kind of curtain self-cutting open Roman hole device for cloth processing, as Figure 5-8 As shown, the cloth roll mechanism includes a first cloth roll seat 20, a second cloth roll seat 25, a cloth roll mandrel 21, a first cloth roll splint 22, a second cloth roll splint 23, a ball head cylinder 24 and a cylindrical spring 26 , the first cloth reel seat 20 and the second cloth reel seat 25 are provided with an upward U-shaped through hole, and the left side of the first cloth reel seat 20 and the right side of the second cloth reel seat 25 also have a circular array of stepped holes. The first cloth reel seat 20 and the second cloth reel seat 25 are symmetrically fixedly connected to the upper side of the rear part of the equipment base 1, and the reel mandrel is detachably connected to the first cloth reel seat 20 and the second cloth reel seat 25 in a U-shaped pass. In the hole, there are hemispherical grooves in a circular array on the...

Embodiment 3

[0054] On the basis of embodiment 2, a kind of curtain self-cutting open Roman hole device for fabric processing, as Figure 13-16As shown, a cloth cutting mechanism is also included, and the cloth cutting mechanism includes a scissors connection horizontal plate 56, a scissors connection slant plate 57, a scissors connection vertical plate 58, a first scissors fixed shaft 59, a first scissors base 60, a second scissors base 61, cloth cutting scissors 62, the second scissors fixed shaft 63, the first scissors connecting rod 64, the second scissors connecting rod 66, the second connecting rod fixed shaft 67, runner shaft 68, spring runner 69, spring connector 71, Runner connection spring 70, cylinder connector 72, the first small wheel connecting rod 73, the second small wheel connecting rod 74, small wheel fixed shaft 75, rotating small wheel 76, scissors pull bar 77, scissors pull head 78, connecting rod side Groove 79, card point connecting plate 80, the first inclined block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com