Corrosive liquid reagent bottle sticker protective tape and manufacturing method thereof

A corrosive and reagent bottle technology, applied in the direction of adhesives, film/sheet adhesives, pressure-sensitive films/sheets, etc., can solve the problems of easy aging, yellowing, inconvenient operation, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

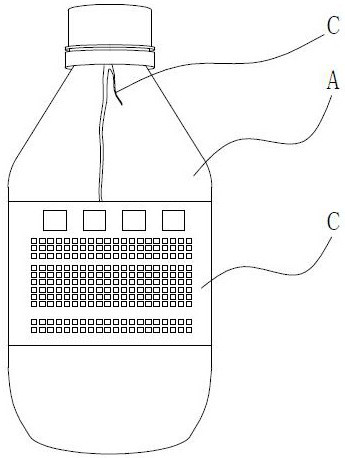

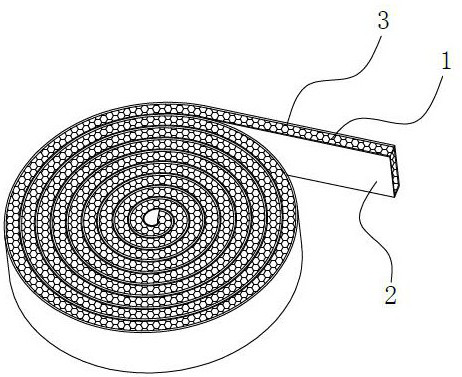

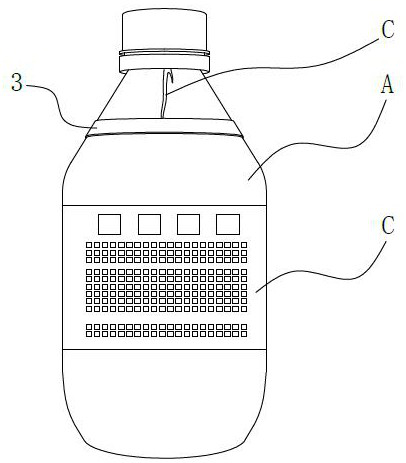

[0032] Figure 4 , 5 The frontal structure and cross-sectional structure of the protective tape on the corrosive liquid reagent bottle involved in this embodiment are respectively shown. It should be pointed out that the protective tape on the corrosive liquid reagent bottle can be curled at normal temperature, and can be made in the factory. to make figure 2 Rolled construction shown for easy portability, storage and use. As shown in the figure, the above-mentioned protective tape for corrosive liquid reagent bottle (hereinafter referred to as protective tape) includes an adsorption layer 1 having pores for absorbing corrosive liquid reagents, and an adhesive layer 2 is provided on the inner side of the adsorption layer 1. The outer side and bottom end of the adsorption layer 1 are provided with a leak-proof layer 3 for preventing the seepage of the corrosive liquid reagent, wherein the top surface of the adsorption layer 1 is exposed and used to contact the corrosive liqu...

Embodiment 2

[0043] The front structure of the protective tape in this embodiment is different from that in Embodiment 1. Like Embodiment 1, the protective tape in this embodiment can also be made as follows in actual production and application. figure 2 Rolled structure shown. The main difference between this embodiment and Embodiment 1 is that the cross-sectional structure is slightly different, see Image 6 As shown, in this embodiment, the inside of the adsorption layer 1 is also provided with a leak-proof layer 3 for preventing the seepage of corrosive liquid reagents, and the adhesive layer 2 is attached to the surface of the leak-proof layer 3 located inside the adsorption layer 1 . The advantage of this design is that the contact between the adhesive layer 2 and the corrosive liquid reagent adsorbed in the adsorption layer 1 can be avoided, thereby reducing the corrosion resistance requirements of the adhesive layer 2 and ensuring the adhesiveness of the adhesive layer 2 and the b...

Embodiment 3

[0050] The difference between this embodiment and Embodiments 1 and 2 is mainly that the top shape of the protective tape is different, Figure 7 The front structure of the protective tape involved in this embodiment is shown, such as Figure 7 As shown, the top surface of the protective tape involved in this embodiment is undulating in wavy shape, and the structure of other parts of the protective tape and the manufacturing method of the tape are the same as those in Embodiment 2, and will not be repeated here. After designing the top surface of the protective tape into a undulating wave shape, the contact area between the top of the adsorption layer 1 and the reagent can be increased, the absorption speed of the reagent liquid C can be improved, and the protective tape can be greatly reduced due to the large flow of the reagent liquid C. The problem that the reagent liquid C overflows through the protective tape and flows to the bottle sticker B due to the lack of time to ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com