Method for controlling appearance quality of New Jersey barrier after construction of slip form paver

A technology of slip form paver and control method, which is applied in the direction of road, road repair, road safety device, etc. It can solve the problems of poor line shape, rough surface, etc., and achieve the effect of easy operation, sharp edges and corners, and consistent color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

[0024] The specific construction process of the M5 highway project in Pakistan will be described below.

[0025] The New Jersey guardrail of this project is constructed with high-performance multifunctional cement slip-form paver. The concrete strength used is A1 (3000psi, about 20Mpa), which is high plasticity and low slump concrete.

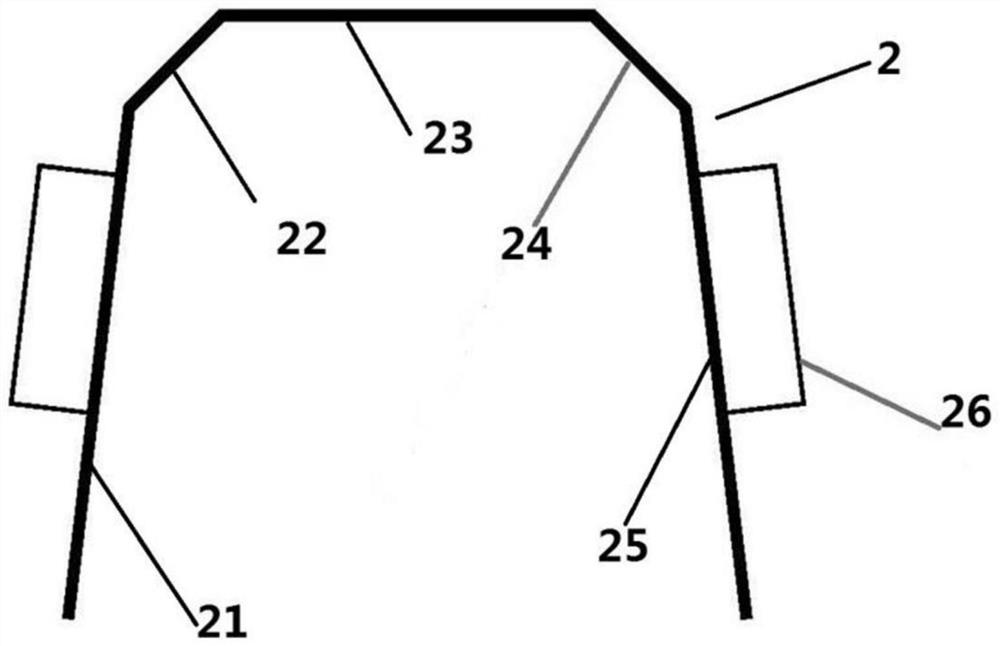

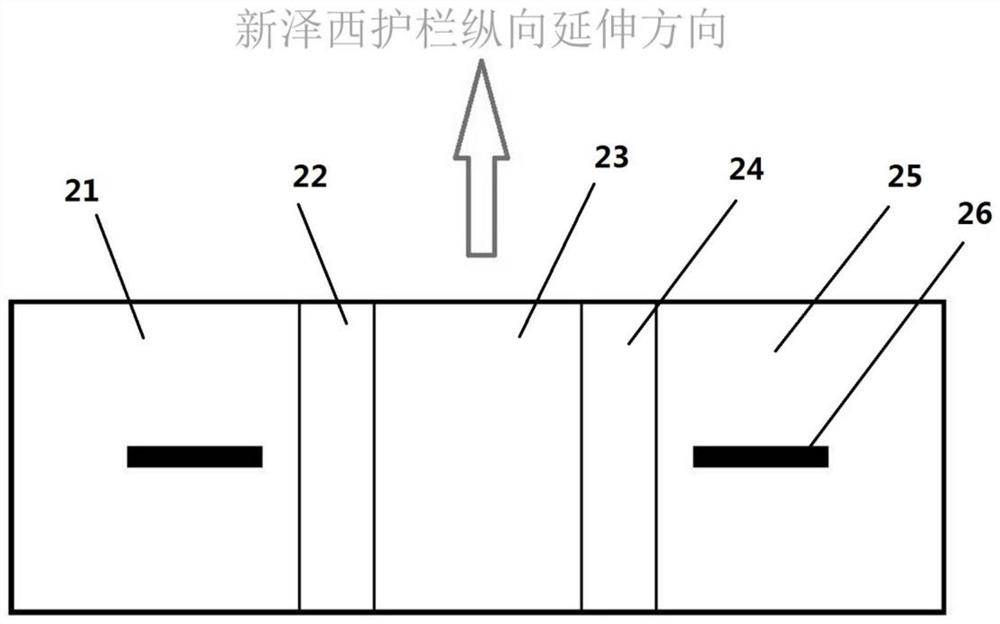

[0026] see Figure 1-4 A method for controlling the appearance quality of the guardrail in New Jersey after the slipform paver construction is shown, including the following steps:

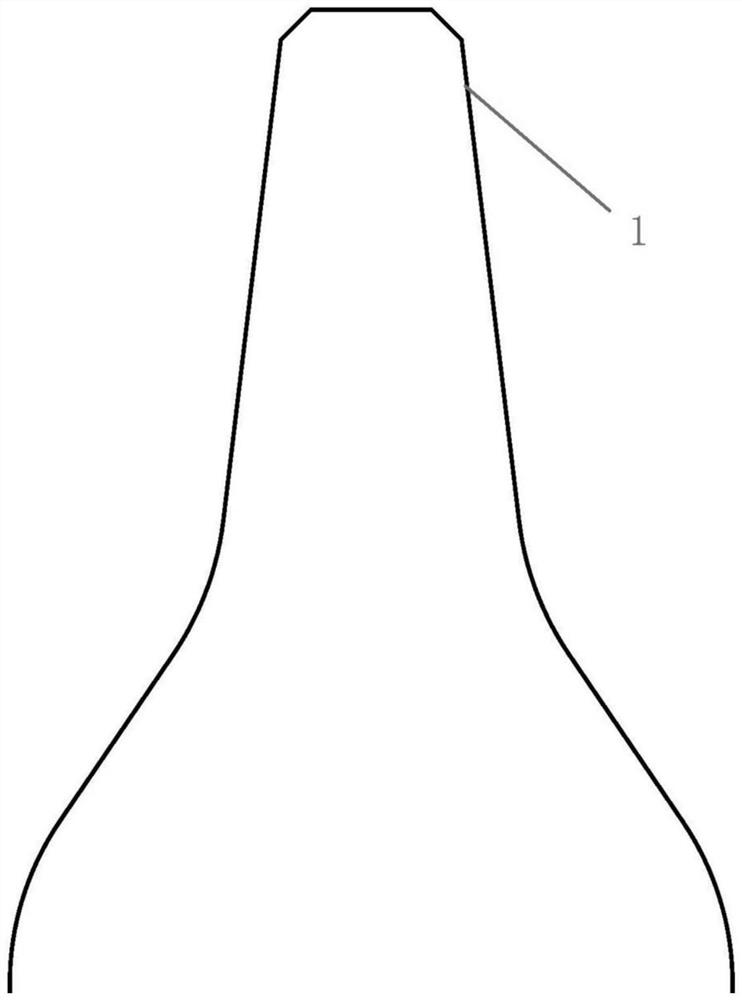

[0027] Step 1: Flattening and compacting: After the concrete is preliminarily formed by the slipform paver template, the small pits on the surface of the New Jersey guardrail 1 and the small cracks on the top surface shall be flattened immediately, and the mortar or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com