Assembling method of special-shaped metal wall plate

A special-shaped metal and assembly method technology, which is applied to building components, walls, buildings, etc., can solve the problems of hoops and angle steel surface corrosion and damage, and the workload of fixing and orthopedic special-shaped panels is large, so as to reduce costs and quickly connect fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

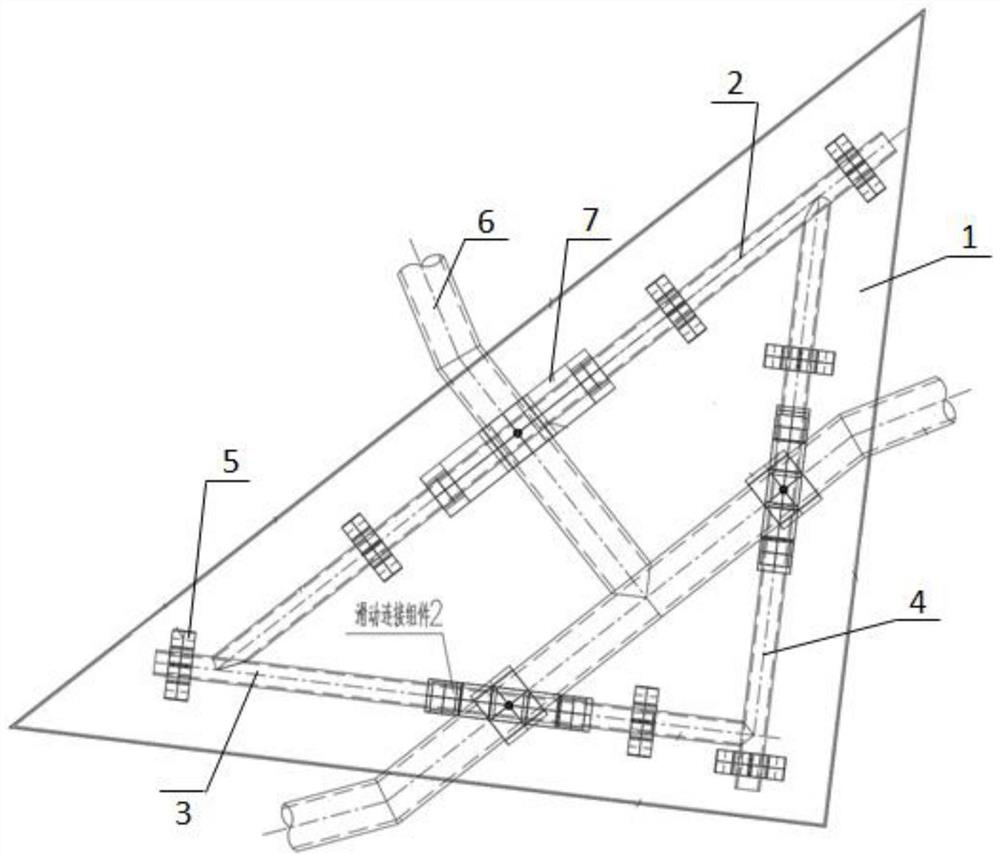

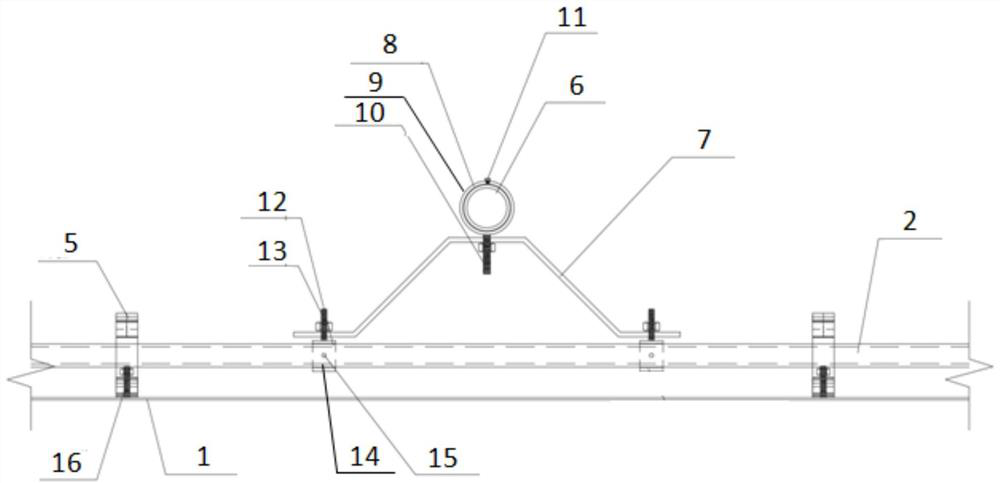

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] A method for assembling special-shaped metal wall panels of the present invention, the overall special-shaped metal adopts an assembled structure, and the special-shaped metal panel 1 is provided with stainless steel tubes I2, stainless steel tubes II3 and stainless steel tubes III4 connected end-to-end in sequence and arranged in a triangle; A steel keel 6 is arranged above the metal panel 1, and the three connecting ends of the steel keel 6 adopt the same connection structure to connect with the stainless steel pipe I2, stainless steel pipe II3, and stainless steel pipe III4 respectively, and the stainless steel pipe and the several-shaped connecting frame 7 pass through The sliding connection assembly II12 is connected and the zigzag connecting frame 7 and the steel keel 6 are connected through the sliding co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com