Rock mass internal fracture visualization three-dimensional similar model device

A technology similar to models and cracks, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve the problem that it is difficult to realize the evolution characteristics of cracks inside the rock mass, the front and rear width is less than 30cm, and it cannot accurately reflect the stope Problems such as the dynamic expansion of cracks in surrounding rocks, to achieve the effect of improving the accuracy of experimental results, improving accuracy, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

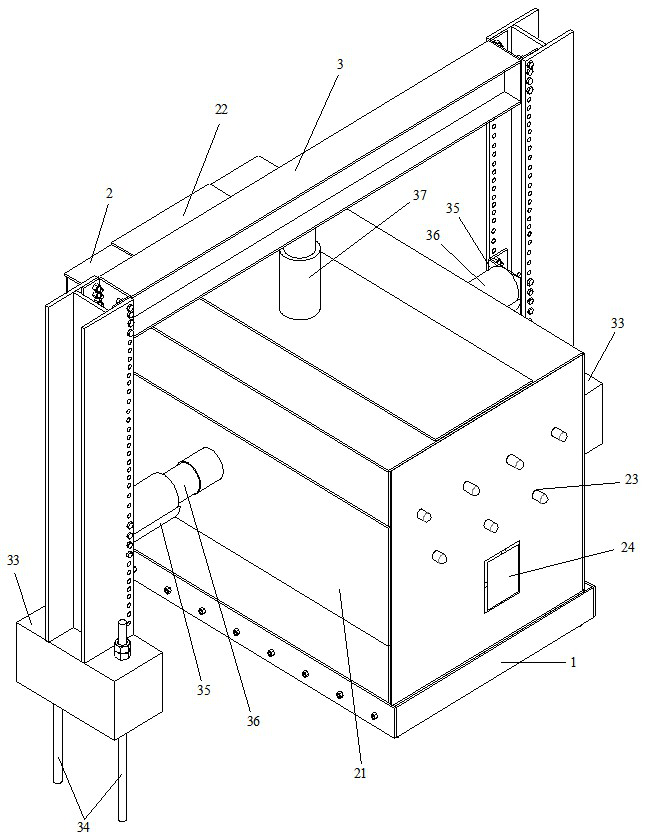

[0035] See figure 1 , a three-dimensional similar model device for visualizing internal cracks in rock mass, including a horizontally arranged rectangular base platform 1, a test box 2 and a loading portal 3, the test box 2 is arranged below the loading portal 3, and passes through the base platform 1 rolling arrangement on the experimental field;

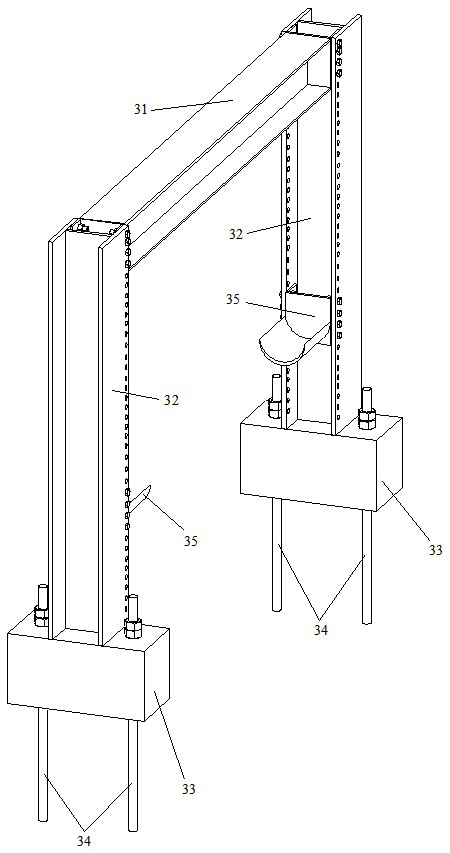

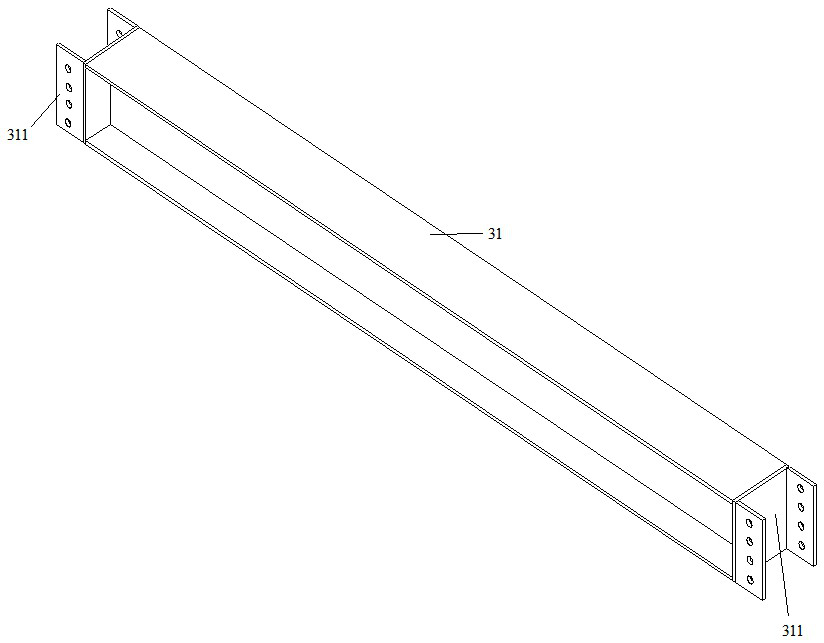

[0036] The loading mast 3 includes a horizontal top beam 31 and a pair of columns 32,

[0037] See figure 2 , each of the columns is an upright H-shaped steel, a pair of webs on a pair of H-shaped steels are arranged in parallel, the lower end of each column is fixed with a rectangular solid steel base 33, and each solid steel base 33 passes through a The high-strength screw mandrel 34 is fixedly installed on the experimental field;

[0038] A pair of groove seats 35 are correspondingly installed on the opposite sides of the pair of columns 32, and a pair of jacks 36 are correspondingly installed on the pair of groove seats 35,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com