Outdoor multi-core rubber-insulated wire optical cable structure

An optical cable and core sheath technology, applied in the field of outdoor multi-core sheathed optical cable structure, can solve problems such as low inspection efficiency and inaccuracy, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

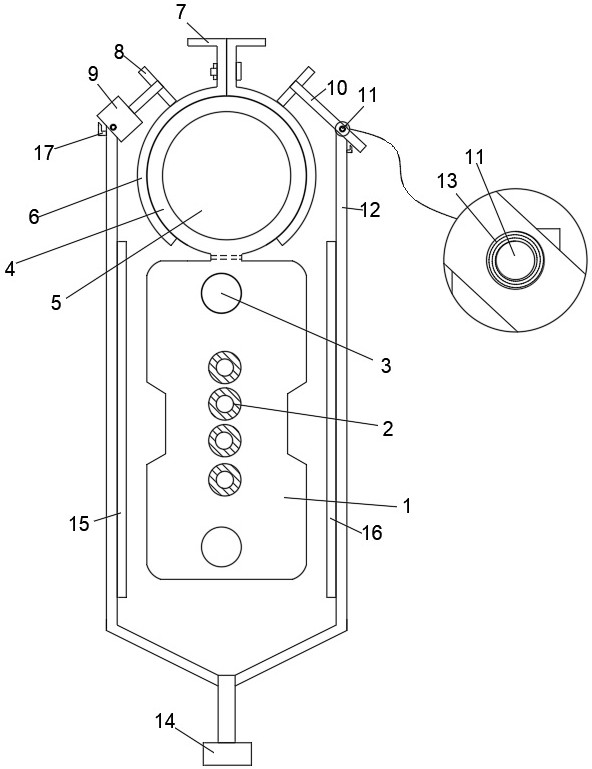

[0015] like figure 1 The outdoor multi-core leather cable structure shown includes a sheath 1, a number of optical cable core wires 2 are fixed inside the sheath 1, first reinforcing wires 3 are fixed on both sides of the optical cable core wire 2; the top of the sheath 1 is connected with Steel wire sleeve 4, reinforcing steel bar 5 is fixed inside the steel wire sleeve 4, two arc-shaped hoops 6 are installed outside the steel wire sleeve 4, angle steel 7 is fixed on the top of the hoop 6, and bolt 8 passes through two angle steels 7 to connect the two hoops. The hoop 6 is fixed together; the two sides of the upper part of the steel wire sleeve 4 are equipped with rollers 8, wherein one roller 8 is connected with a rotating device 9, the rotating device 9, and the other roller 8 is connected with a rotating shaft 10; the rotating device 9 and the rotating shaft 10 are respectively A U-shaped frame 12 is hingedly connected by a rotating shaft 11, and the rotating shaft 11 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com