Method for controlling and in particular monitoring an actuator, in particular of a winch, a hoist or a crane, and system for carrying out such a method

A technology for actuators and elevators, applied in cranes, monitoring, reversing, transportation and packaging, etc., can solve the problem of unreliable calculation of expected value of frequency converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

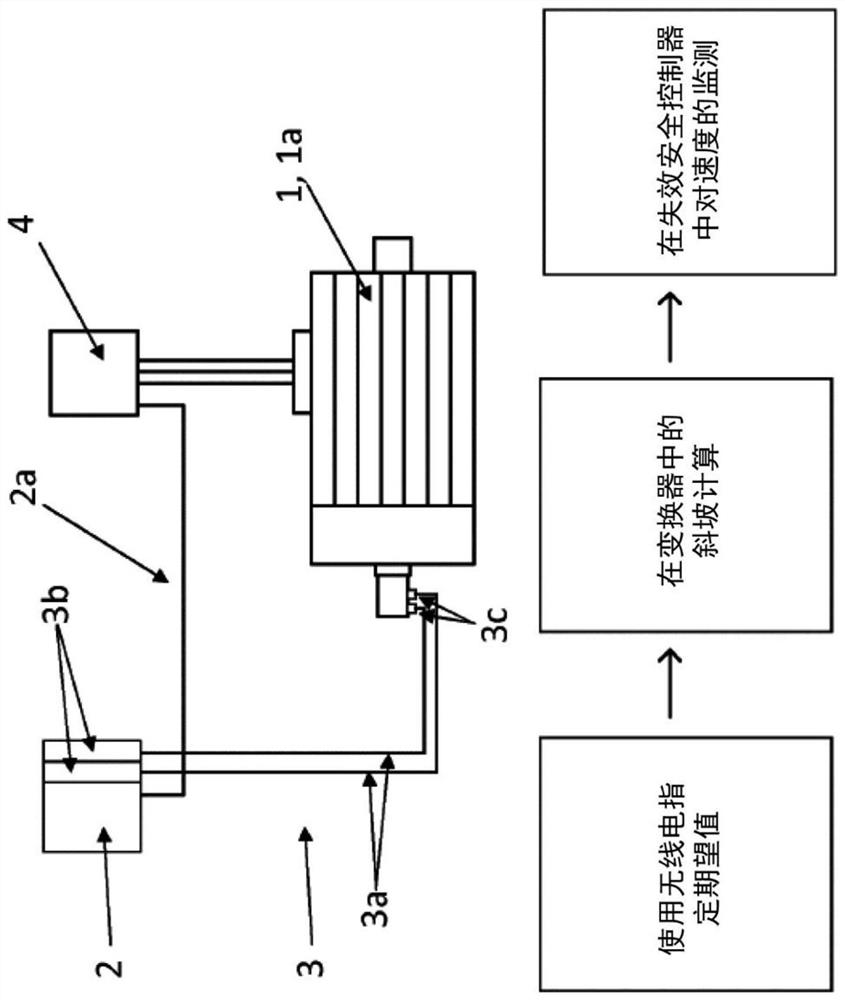

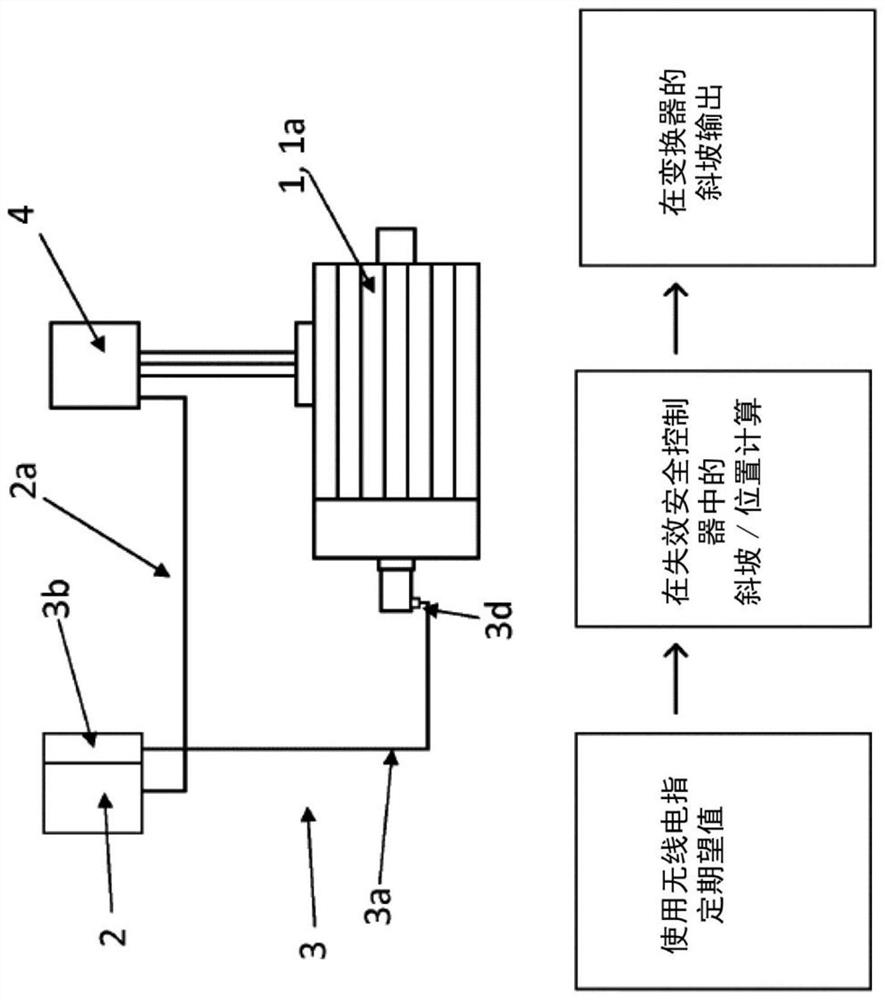

[0032] figure 1 A system for controlling and monitoring a drive actuator 1 according to the prior art already described in the introduction is shown. In this case, the actuator 1 is part of an electric motor 1a, which is designed by way of example as a frequency converter-controlled electric motor and can be a drive motor of a winch, a hoist or a crane. An operating part (not shown), which is also defined as a control point and can be, for example, a radio remote control or a radio controller, can be used to control the actuator 1, because, by actuating the operating elements of the operating part, the control commands Can be specified for actuator 1. A control command can eg be "move at maximum speed in forward direction" or "move at speed 1 m / min in backward direction". Starting from the operating part, signals corresponding to the respective control commands are transmitted from the fail-safe control unit 2 via the control line 2 a to the converter 4 designed as a frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com