Accurate flow control unit for tea production line

A flow control and production line technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of non-uniform discharge, coke flakes, non-equipment, etc., and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

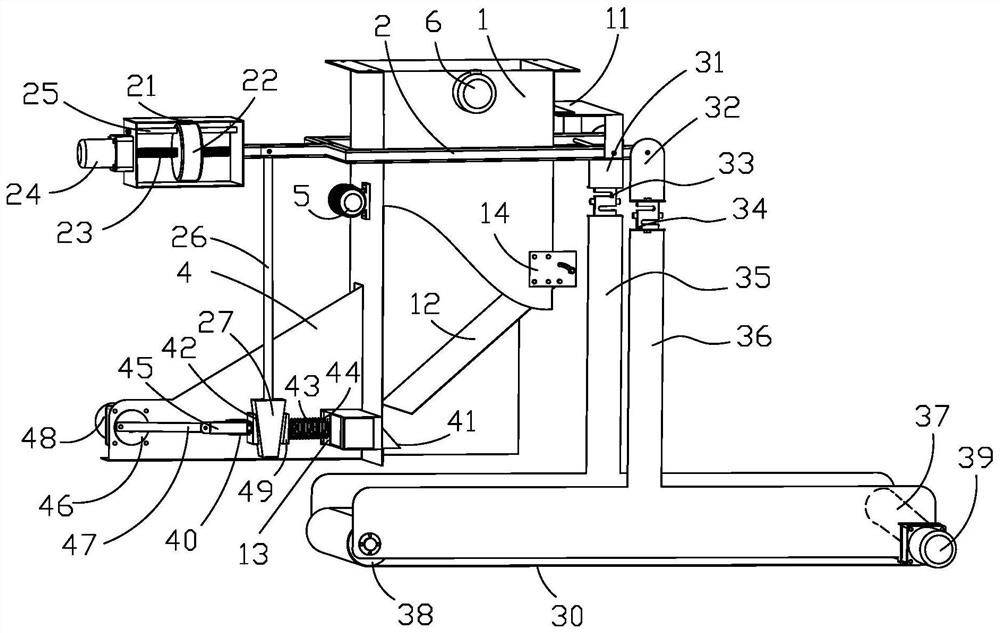

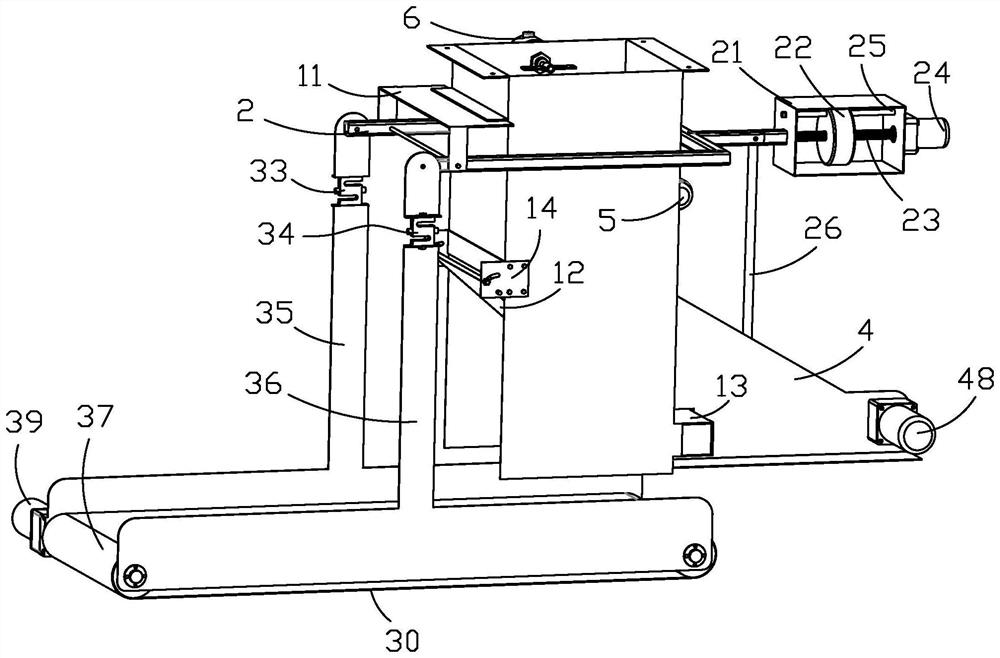

[0040] refer to figure 1 , figure 2 , a precise flow control unit for a tea production line proposed in this embodiment, comprising: a feed hopper (1), a power mechanism, an elastic push rod mechanism, a conveyor belt (30) and an adjustment mechanism.

[0041] The feeding hopper 1 is provided with a discharge port, and the conveyor belt 30 is arranged below the discharge port. The conveyor belt 30 is used to transport the tea leaves to a designated location.

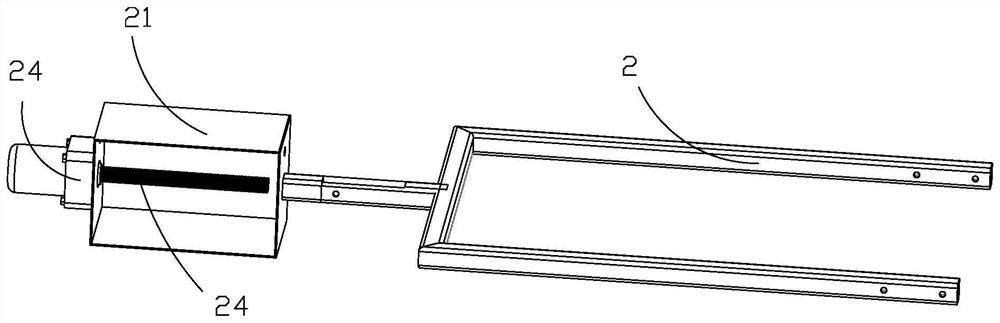

[0042] The adjustment end of the end of the elastic push rod mechanism is inserted into the discharge port, the push rod of the elastic push rod mechanism moves back and forth under the action of its own elastic force and the power mechanism, and the adjustment end moves back and forth following the push rod to adjust The opening of the outlet.

[0043] The adjustment mechanism is used to adjust the thrust of the power mechanism to the elastic push rod mechanism according to the load bearing of the conveyor belt (30)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com