Construction method for heat treatment of welded joints of dissimilar rails

A construction method and technology for welding joints, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., to achieve the effects of ensuring railway operation safety, improving wear and tear, and good joint toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

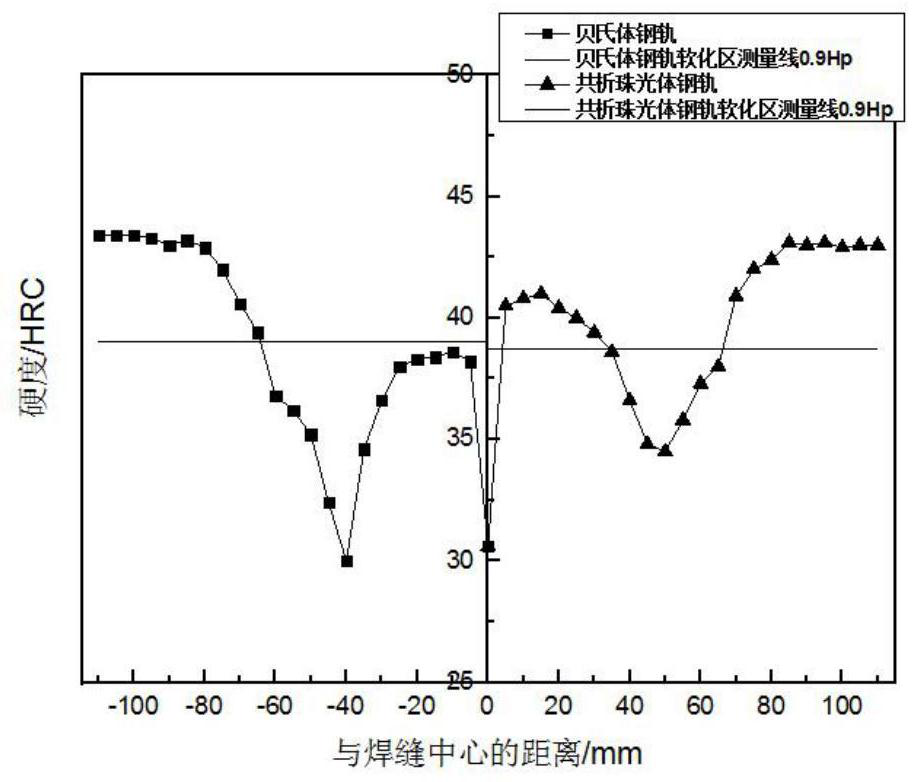

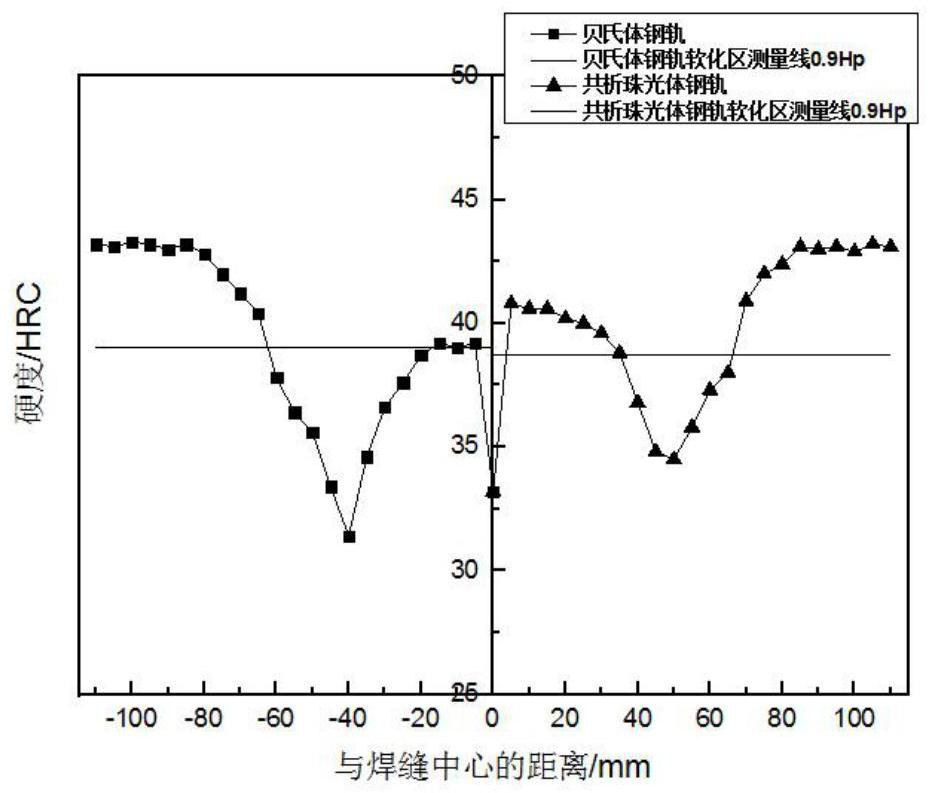

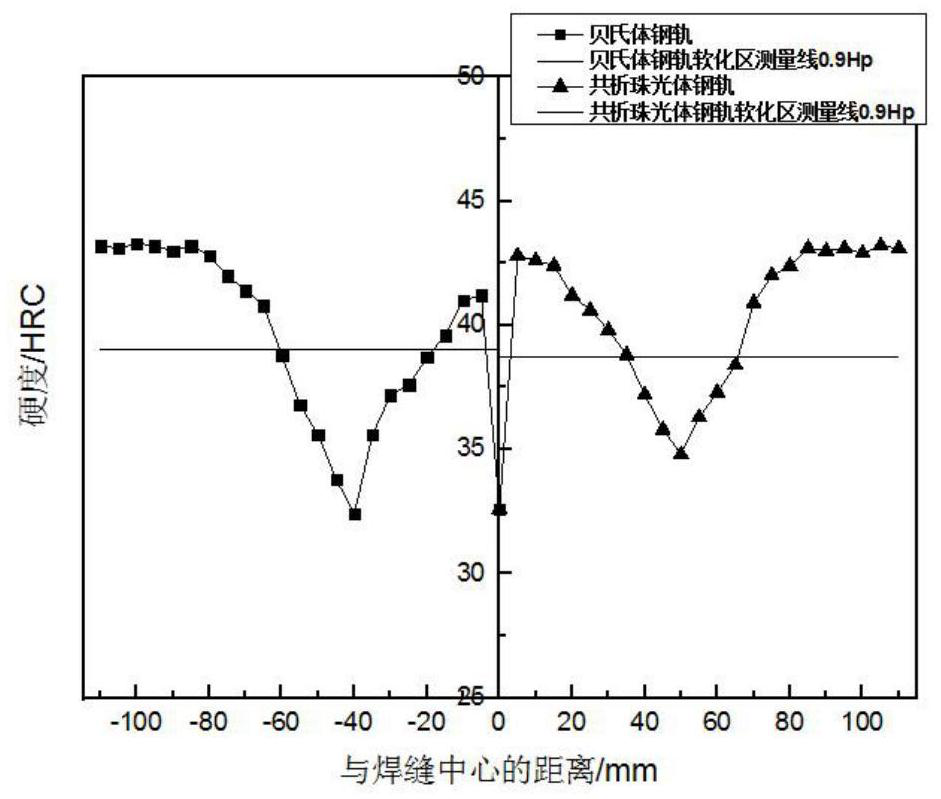

Image

Examples

Embodiment 1

[0056] After the dissimilar rails with a specification of 75kg / m are upset and pushed during the mobile flash welding process, the welded joints are subjected to post-weld heat treatment. Firstly, the dissimilar rail joints obtained by welding with a residual temperature of 1200 °C are placed in the air to cool naturally to reduce the surface temperature of the rail head of the rail joints to 200 °C; Heating the entire cross-section, and stop heating when the temperature of the rail tread reaches 950°C; then use compressed air as the cooling medium, and perform rapid cooling at a cooling rate of 3.0°C / s, and the final cooling temperature at this stage is 430°C; The third cooling rate of ℃ / s is used for the third-stage cooling to reduce the surface temperature of the rail head of the rail joint to 170 °C; then, use a split-type electric heating and tempering device to heat the welded joint of the rail with a surface temperature of 170 °C Tempering heat treatment at 350°C with a...

Embodiment 2

[0064] After the dissimilar rails with a specification of 68kg / m are upset and pushed during the mobile flash welding process, post-weld heat treatment is performed on the welded joints. Firstly, the dissimilar rail joints obtained by welding with a residual temperature of 1250 °C are placed in the air for natural cooling to reduce the surface temperature of the rail joint rail head to 150 °C; Heating the entire cross-section, and stop heating when the temperature of the rail tread reaches 930°C; then use compressed air as the cooling medium, and perform rapid cooling at a cooling rate of 2.5°C / s, and the final cooling temperature at this stage is 400°C; then, use 0.6°C The third cooling rate of ℃ / s is used for the third-stage cooling to reduce the surface temperature of the rail head of the rail joint to 160 °C; then, use a split-type electric heating and tempering device to heat the welded joint of the rail with a surface temperature of 170 °C Tempering heat treatment at 320...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com