Post-weld heat treatment method for rail

A technology for post-weld heat treatment and steel rails, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of complex operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

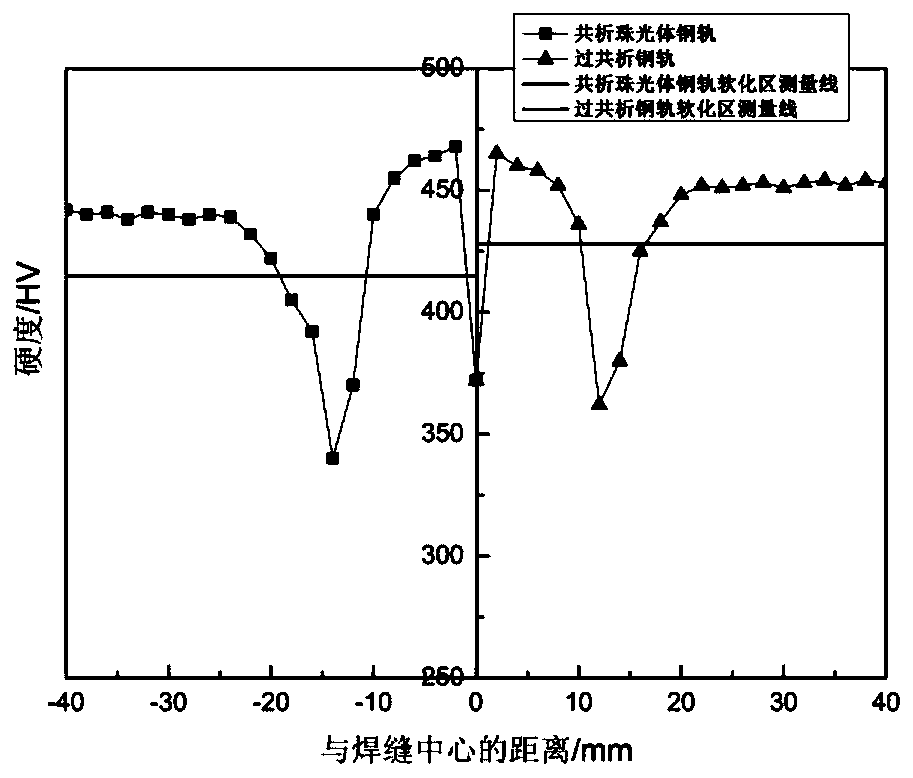

[0041] After the hypereutectoid steel rail and eutectoid pearlitic steel rail with a specification of 75kg / m are upset and pushed during the moving flash welding process, post-weld heat treatment is performed on the welded joint. Firstly, the rail joint with residual temperature of 1100 °C obtained by welding is cooled in the first stage at the first cooling rate of 4.9 °C / s to reduce the surface temperature of the rail head of the rail joint to 630 °C, and then the rail joint is cooled at 2.0 °C The second cooling rate of / s is used for the second-stage cooling to reduce the surface temperature of the rail head of the rail joint to 220°C, and finally the rail joint is subjected to the third-stage cooling at a third cooling rate of 0.4°C / s to reduce the temperature of the rail joint The temperature of the surface layer of the rail head is lowered to the room temperature of 25° C., thereby obtaining the welded joint of the rail with post-weld heat treatment of the present invent...

Embodiment 2

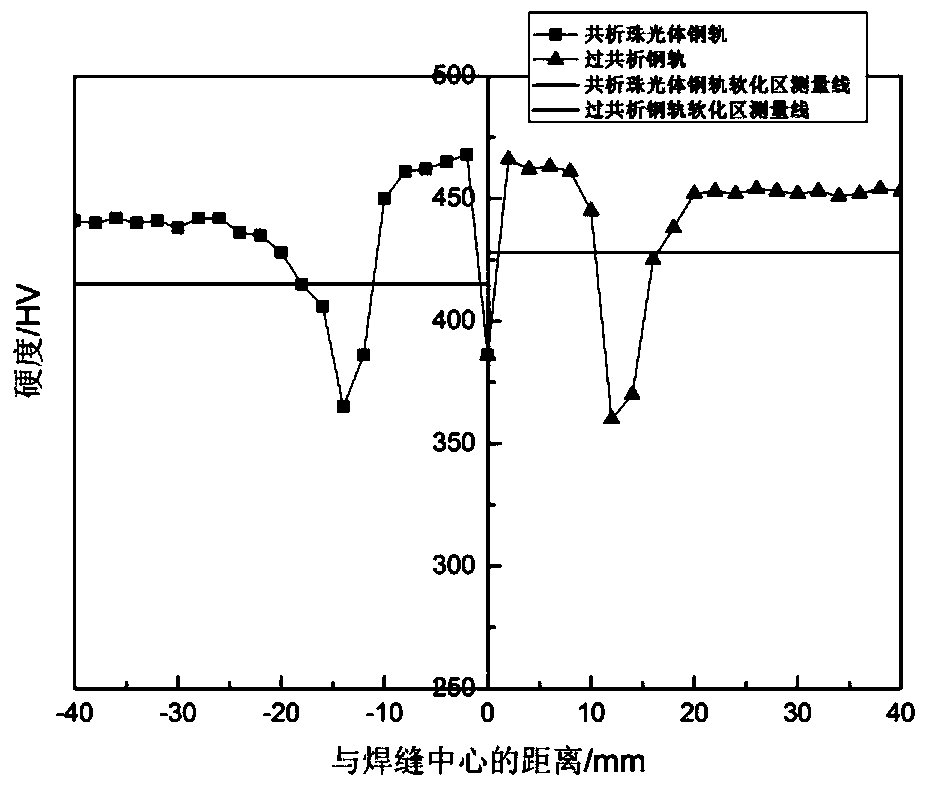

[0049] After the hypereutectoid steel rail and eutectoid pearlitic steel rail with a specification of 60kg / m are upset and pushed during the moving flash welding process, post-weld heat treatment is performed on the welded joint. Firstly, the rail joint with residual temperature of 1000 °C obtained by welding is cooled in the first stage at the first cooling rate of 4.2 °C / s to reduce the surface temperature of the rail head of the rail joint to 620 °C, and then the rail joint is cooled at 2.3 °C The second cooling rate of / s is used for the second-stage cooling to reduce the surface temperature of the rail head of the rail joint to 185°C, and finally the rail joint is subjected to the third-stage cooling at a third cooling rate of 0.10°C / s to reduce the temperature of the rail joint The temperature of the surface layer of the rail head is lowered to room temperature of 25° C., thereby obtaining the post-weld heat-treated rail welded joint of dissimilar materials of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com