Condenser automatic cleaning equipment

An automatic cleaning and condenser technology, applied in the direction of cleaning heat transfer devices, lighting and heating equipment, flushing, etc., can solve problems such as waste of labor, safety accident quality, hidden dangers, etc., to ensure internal cleanliness, avoid cleanliness, The effect of high-quality work done

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

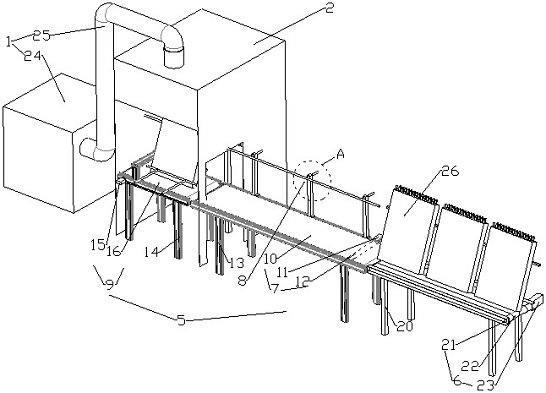

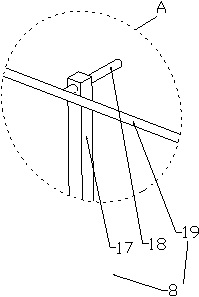

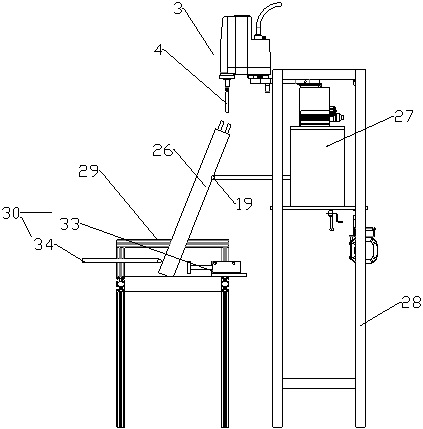

[0025]Such asfigure 1 The automatic condenser cleaning equipment shown includes: a separating and conveying device 5, which is used to separate and convey the condenser 26; a cleaning cover 2, the cleaning cover 2 has a cleaning cavity and the cleaning cover 2 is located in the separation Above the output end of the conveying device 5; cleaning head 4, which is movably connected to the cleaning cavity through the first drive mechanism 3, and is used to clean the oxide scale of the condenser 26; negative pressure recovery device 1, The negative pressure recovery device 1 is located at the side end of the cleaning cover 2 and can communicate with the cleaning cavity, and is used to recover the oxide scale that has been washed away.

[0026]In this embodiment, the solution can be used to automatically purify the air conditioner condenser oxide scale, and the manual operation can be completely replaced by the automatic device to ensure efficient and high-quality completion of the work; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com