Large-mass weight automatic calibration device

A verification device and high-mass technology, applied in the field of weight calibration, can solve the problems of damage to the comparator, prone to errors, heavy weight of large-mass weights, etc., and achieve the effect of reducing the damage rate and reducing the impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

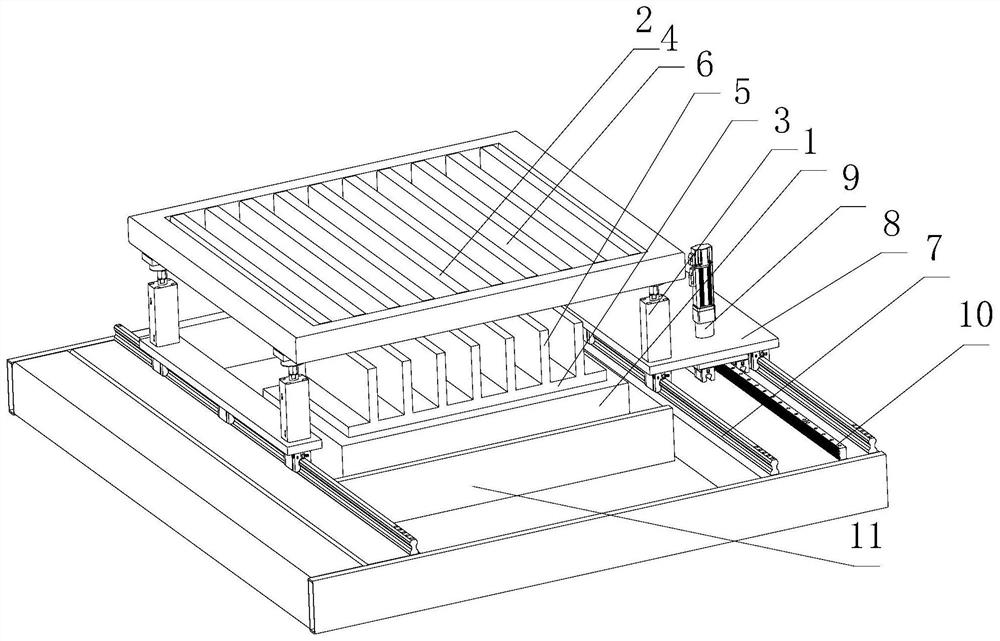

[0022] Such as figure 1 As shown, the present embodiment includes a comparator 1, a lifting platform 2, a lifting device 3, a guide rail 7, a placement platform 8 and a drive assembly, the placement platform 8 is slidingly connected to the guide rail 7, and the drive assembly can drive the placement platform 8 Slide on the guide rail 7, the lifting device 3 is arranged on the placement platform 8, the lifting platform 2 is connected with the output shaft of the lifting device 3, the lifting device 3 can drive the lifting platform 2 to move up and down, the upper part of the comparator 1 The end face is connected with a carrying platform 5 , and a through hole 4 is opened on the lifting platform 2 , and the upper end surface of the carrying platform 5 can pass through the through hole 4 and be located above the lifting platform 2 .

[0023] In this embodiment, the driving assembly includes a motor 9 and a rack 10, the rack 10 is arranged in parallel with the guide rail 7, the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap