Triple concurrent fault analysis method, system, large unit equipment and storage medium

A fault analysis method and technology of fault analysis, applied in the testing of computer components, mechanical components, machine/structural components, etc., can solve problems such as inaccurate prediction accuracy, difficult feature extraction, incomplete feature extraction, etc., to achieve The effect of solving the fault prediction problem, comprehensive features, and rapid calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

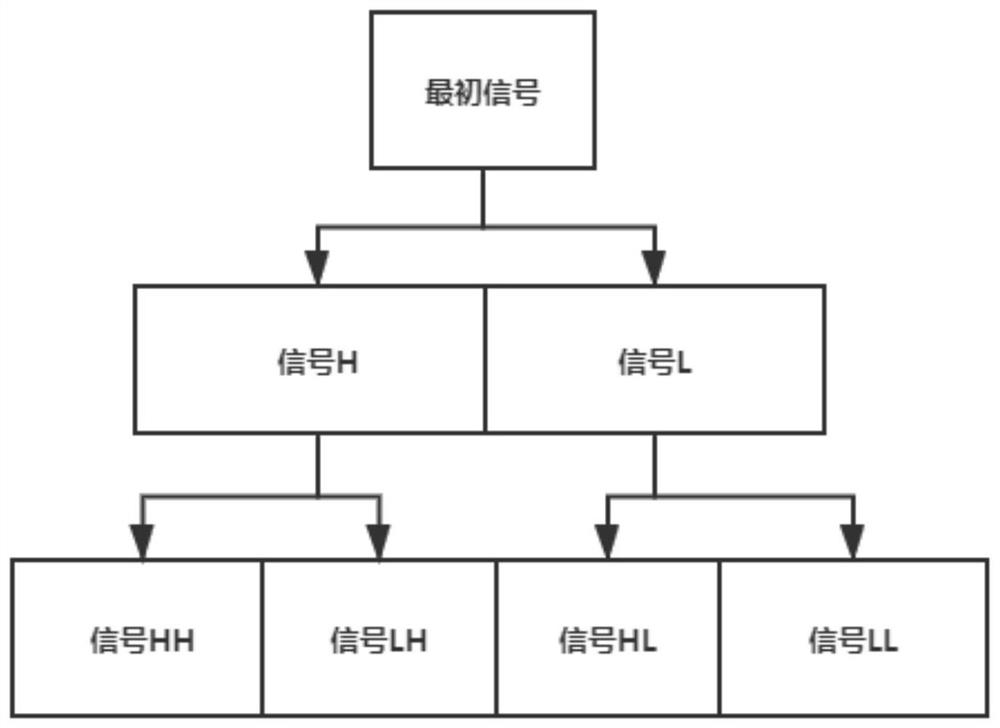

[0072] Aiming at the problems existing in the prior art, the present invention provides a triple concurrent fault analysis method based on dimensionless and wavelet decomposition feature learning and gradient enhanced trees. The present invention will be described in detail below in conjunction with the accompanying drawings.

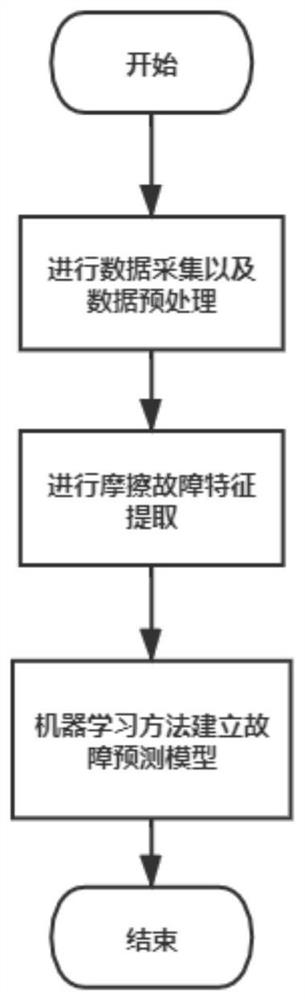

[0073] The triple concurrent fault analysis method based on dimensionless and wavelet decomposition feature learning and gradient enhanced tree provided by the embodiment of the present invention is as follows: figure 1 As shown, the specific implementation is as follows:

[0074] Step 1, data coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com