A Triple Simultaneous Fault Analysis Method Based on Spectrum Data of Double Measuring Points x,y

A fault analysis method and spectrum data technology, which are applied in the field of triple concurrent fault analysis based on X, Y double measuring point spectrum data, can solve the problems of incomplete feature extraction, difficulty in feature extraction for friction fault diagnosis of large units, etc. The effect of predicting problems, comprehensive features, and rapid calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

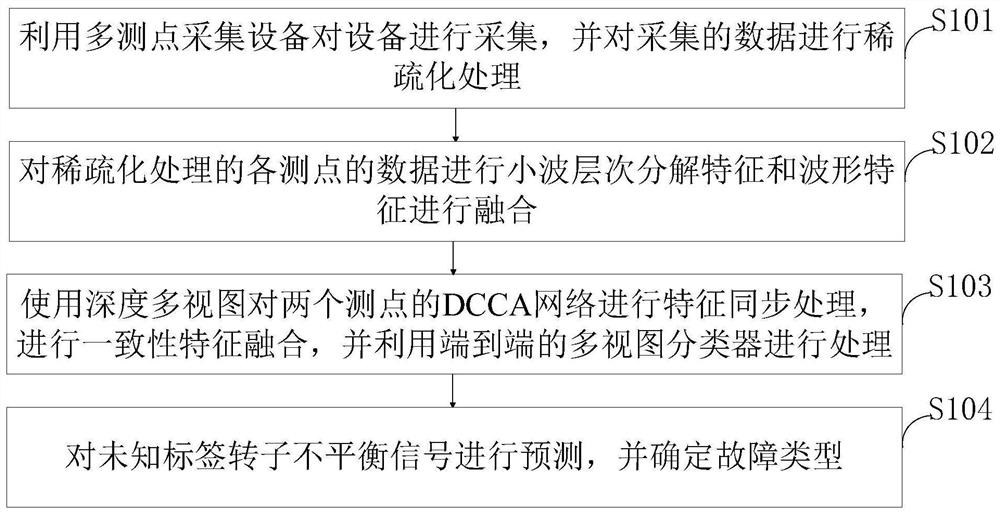

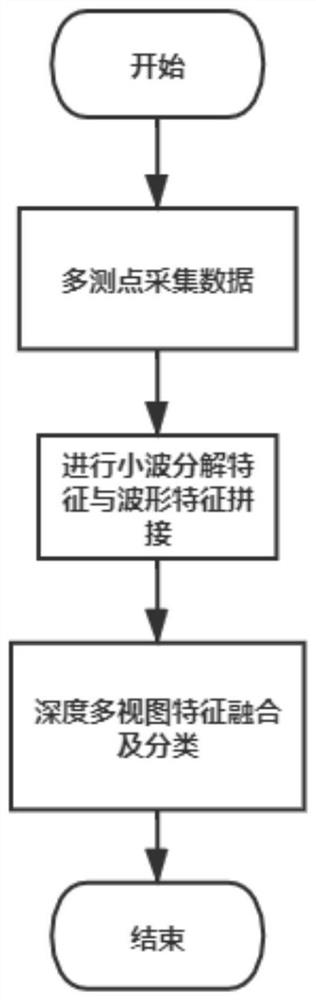

[0130] The implementation flow chart of the present invention is as figure 1 As shown, the specific implementation is as follows:

[0131] In step 1, use multi-measuring point collection equipment to collect the equipment and sparse the data, which specifically includes the following steps:

[0132] Step 1.1, install two probe points, and obtain the vibration dual-view signal of the large sliding unit through the two probe points. The data collection is 32 / rms, that is, 32 points are sampled for each revolution of the bearing, and the data of 32 revolutions is collected.

[0133] Step 1.2, after the probe collects data, discrete Fourier transform is performed on the two views respectively, the window size is 32*32=1024 points, and the adaptive threshold is set according to the signal condition to reduce the signal storage capacity and speed up the transmission. Its conversion formula is as follows:

[0134] Where n=0,...,N-1, N represents the data length.

[0135] Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com