A Rotating Machinery Fault Prediction Method Based on Scattering Transform

A technology of scattering transformation and fault prediction, which is applied to computer parts, instruments, calculations, etc., can solve the problems of unreliable threshold value, discretization of rough set method, unsuitable for continuous numerical change, etc., and improve translation invariance and elasticity Deformation stability, solving the fault prediction problem, and increasing the effect of information redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

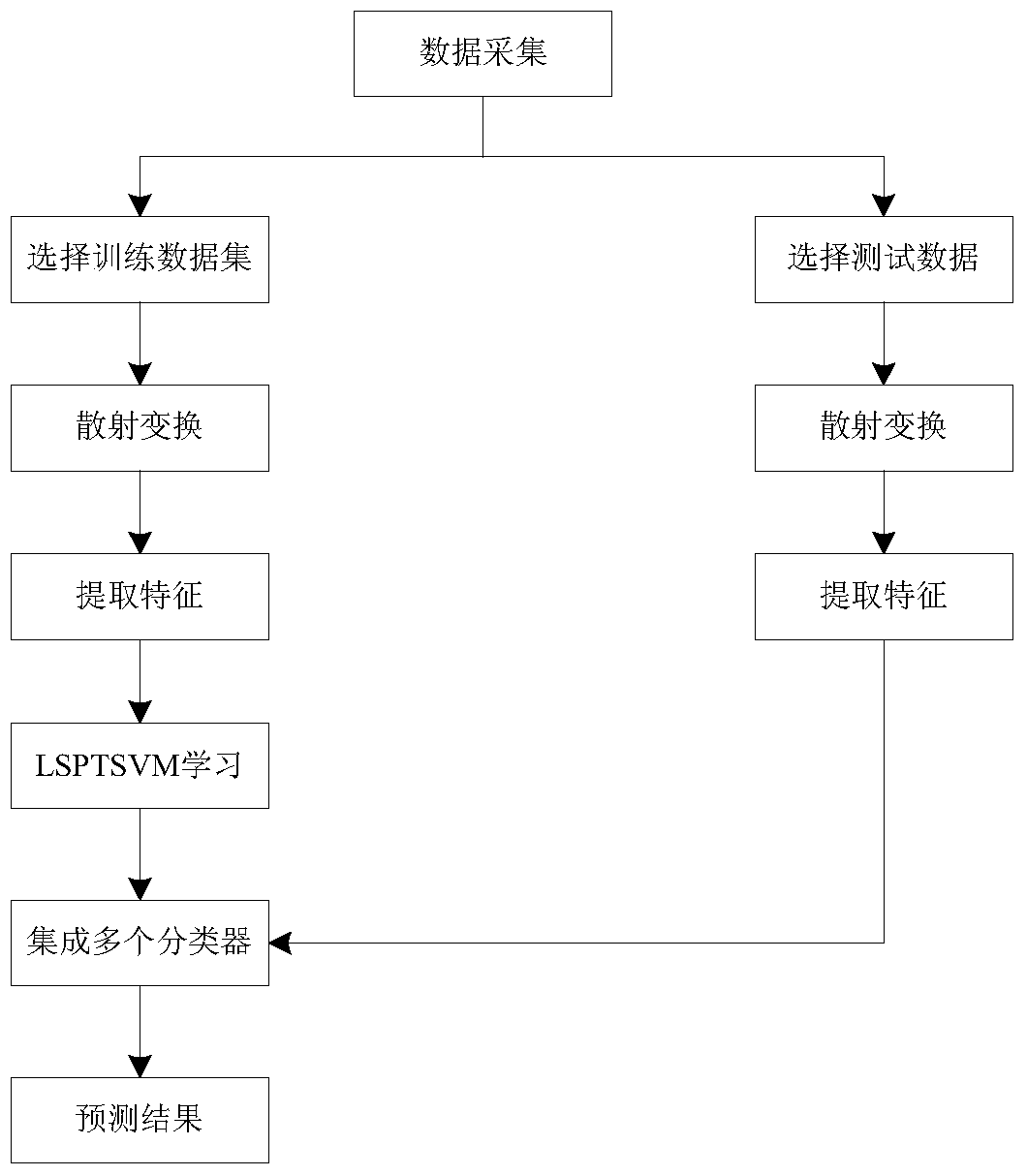

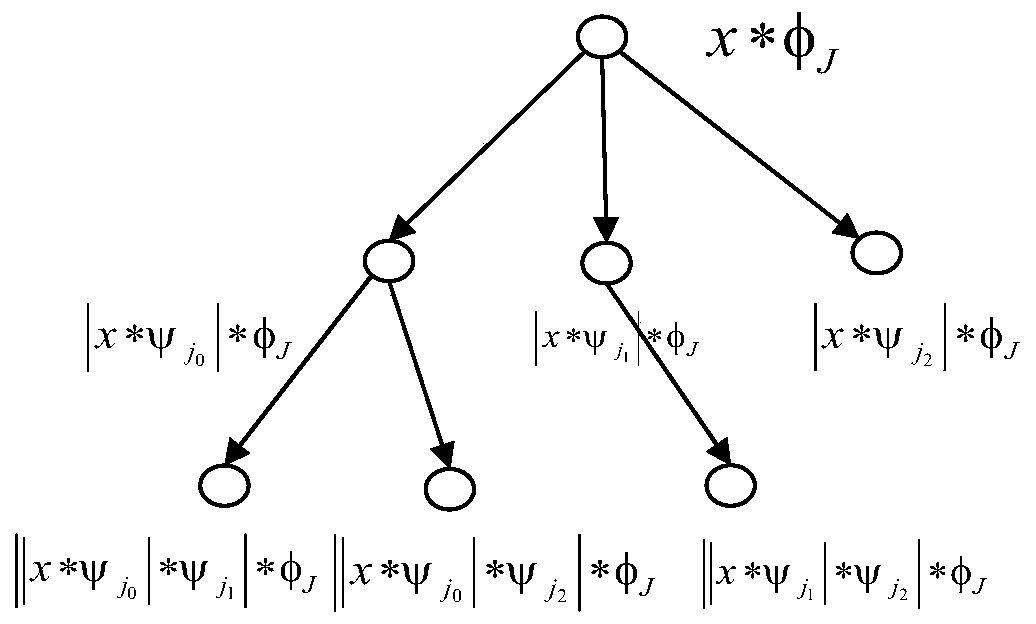

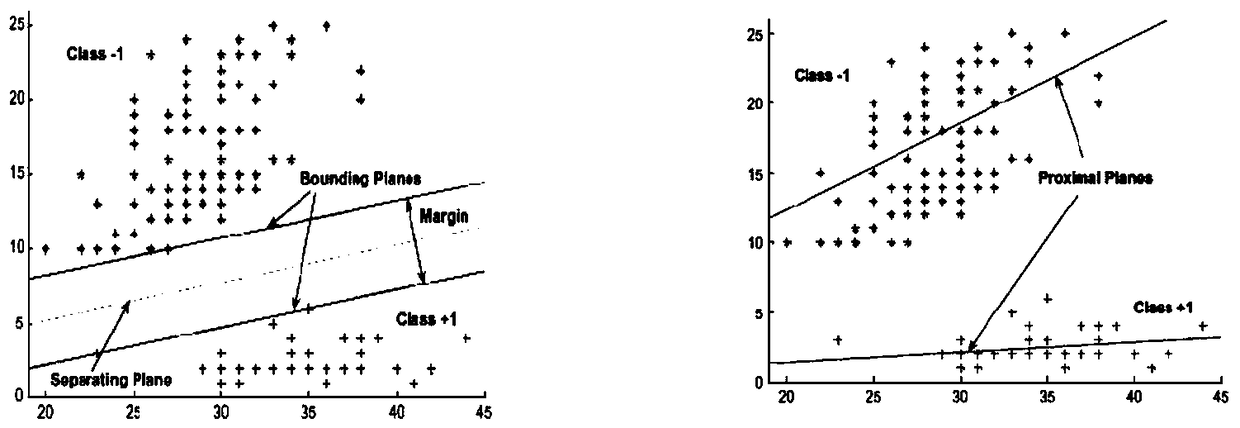

[0035] A fault prediction method for rotating machinery based on scattering transform, by using the non-subsampled dual-tree complex wavelet scattering transform, its translation invariance and elastic deformation stability are improved, information redundancy is increased, and it is beneficial to extract The feature has a better representation ability, and it can better solve the problem of fault prediction of rotating machinery signals. This method is mainly based on the scattering transformation and consists of three parts: 1. Signal acquisition; 2. Feature transformation and fault feature extraction, the scattering transformation is performed on the original signal to obtain the scattering transformation coefficient, and then the scattering transformation of each subband The energy value of the coefficient is calculated as the character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com