Zoom system

A magnification ring and magnification technology, which is applied in the field of magnification system, can solve problems such as wear, deformation, and magnification errors detected by components, and achieve the effects of improving measurement accuracy, eliminating errors, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

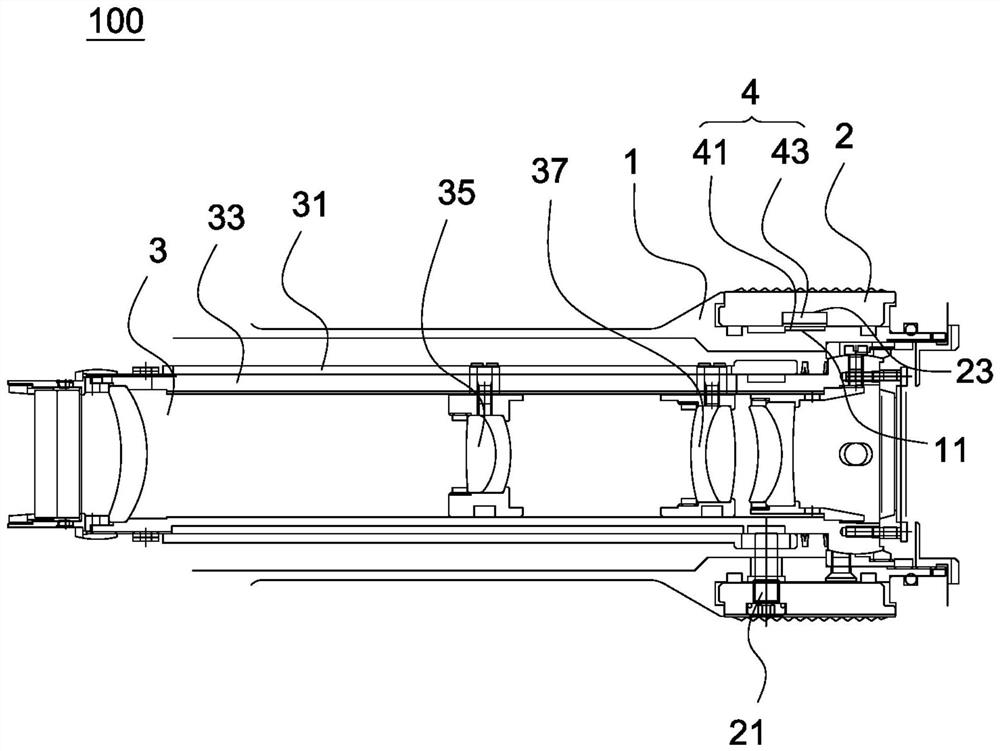

[0018] see figure 1 One embodiment of the zoom system 100 of the present invention includes a main body 1 , a zoom ring 2 , an optical lens group 3 , a conversion unit 4 and a processing unit (not shown). Among them, the zoom ring 2 rotates relative to the main body 1 to control the optical lens group 3, thereby adjusting the magnification of the zoom system 100, and the conversion unit 4 is used to convert the rotation information (such as the rotation angle or the number of rotations) of the zoom ring 2 An electrical signal corresponding to the magnification of the zoom system 100 is generated, and the processing unit can calculate the magnification of the zoom system 100 according to the electrical signal. The assembly of these components is detailed below:

[0019] It is worth noting that the zoom system 100 is suitable for devices requiring optical zoom, such as sighting devices, telescopes, distance measuring devices, and camera barrels. Wherein, the aiming device is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com