transport vehicle

A transport vehicle and bearing platform technology, applied in the field of transport vehicles, can solve the problems of anti-plate-to-anti-plate damage and anti-plate confusion, and achieve the effects of improving transportation efficiency, avoiding wear and solving mutual wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

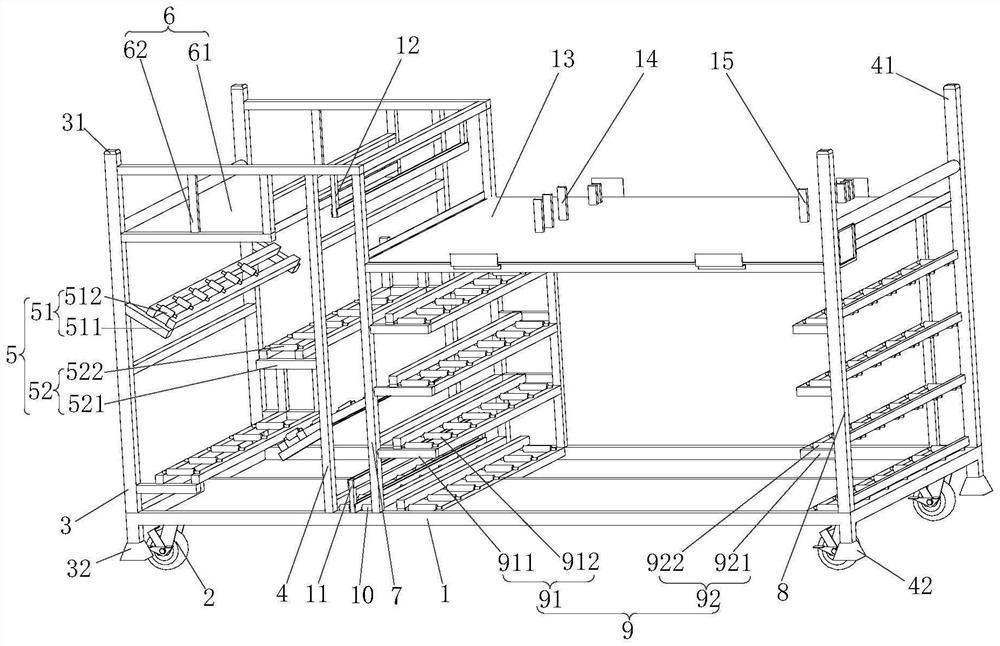

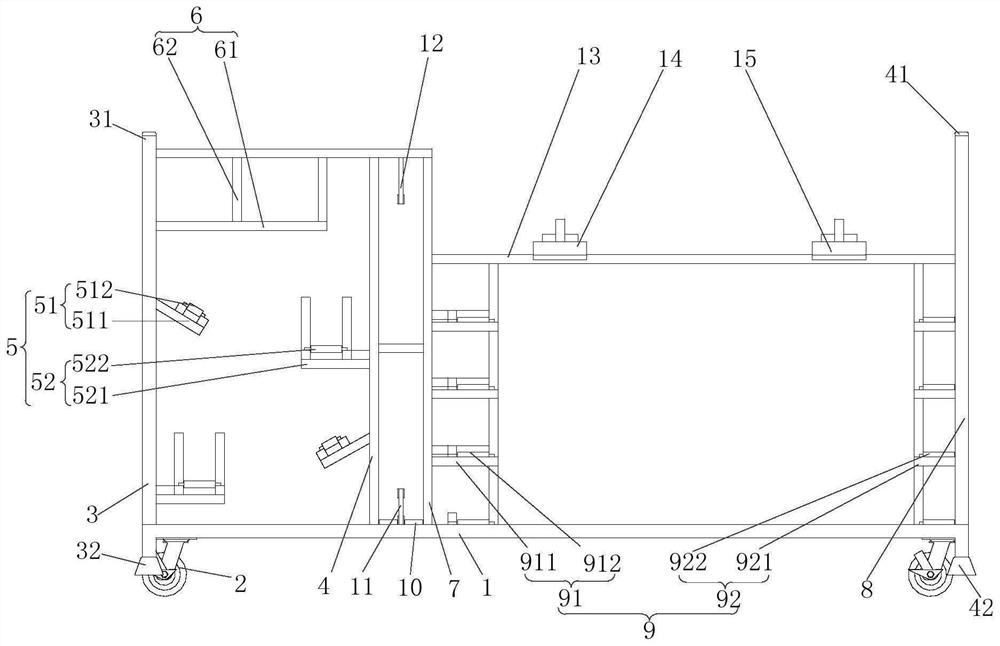

[0046] like Figure 1-2As shown, a transport vehicle proposed in Embodiment 1 of the present invention includes: a first support 3 and a second support 4 of a base 1, and a plurality of first bearing frames 5; the lower surface of the base 1 is provided with rollers 2 , the first bracket 3 and the second bracket 4 are oppositely arranged on the upper surface of the base 1, and there is a first preset distance between the first bracket 3 and the second bracket 4; The first carrier 5 is vertically spaced between the first bracket 3 and the second bracket 4, and the first carrier 5 includes a The connected first sliding platform 51 and the second sliding platform 52 have a preset angle between the first sliding platform 51 and the second sliding platform 52 .

[0047] Specifically, the base 1 is the main carrier of the transport vehicle provided in the embodiment of the present invention, which can be a plate-shaped seat, such as a rectangular plate-shaped seat, or a frame-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com