Detection device for power line fault monitoring equipment

A fault monitoring and detection device technology, which is applied to cable installation devices, equipment for dismantling/armored cables, and cable installation, can solve problems such as occupying the ground and space, hindering traffic and viewing, and difficult stripping, etc., to achieve Fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

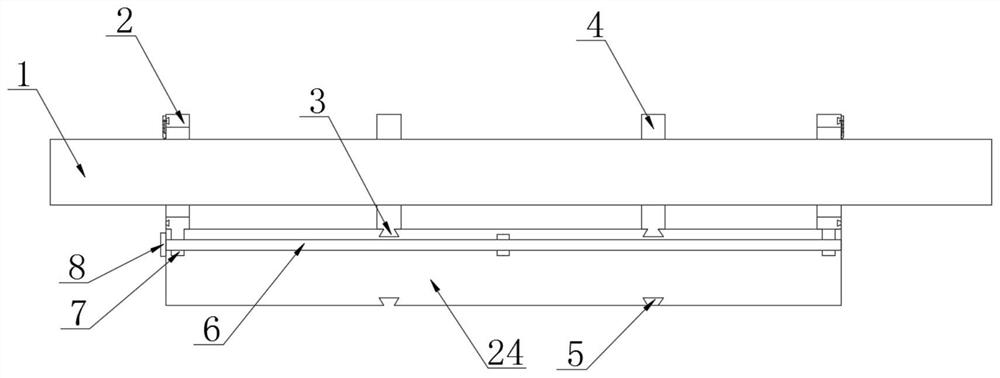

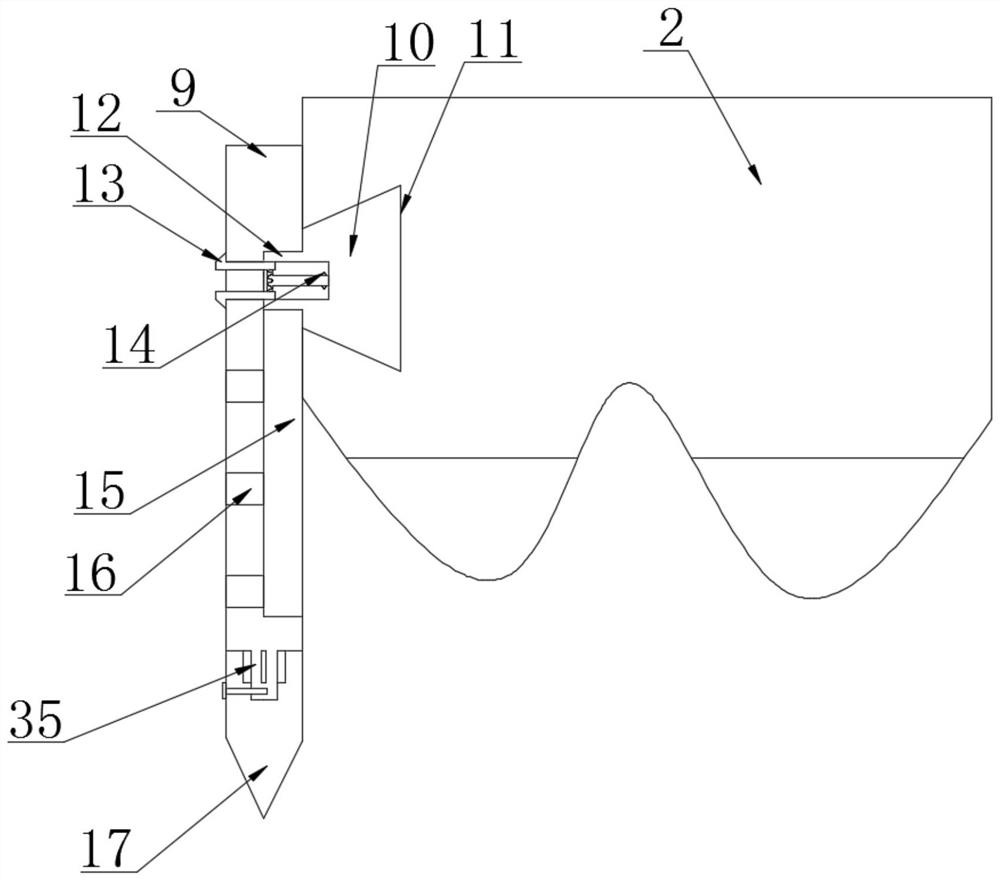

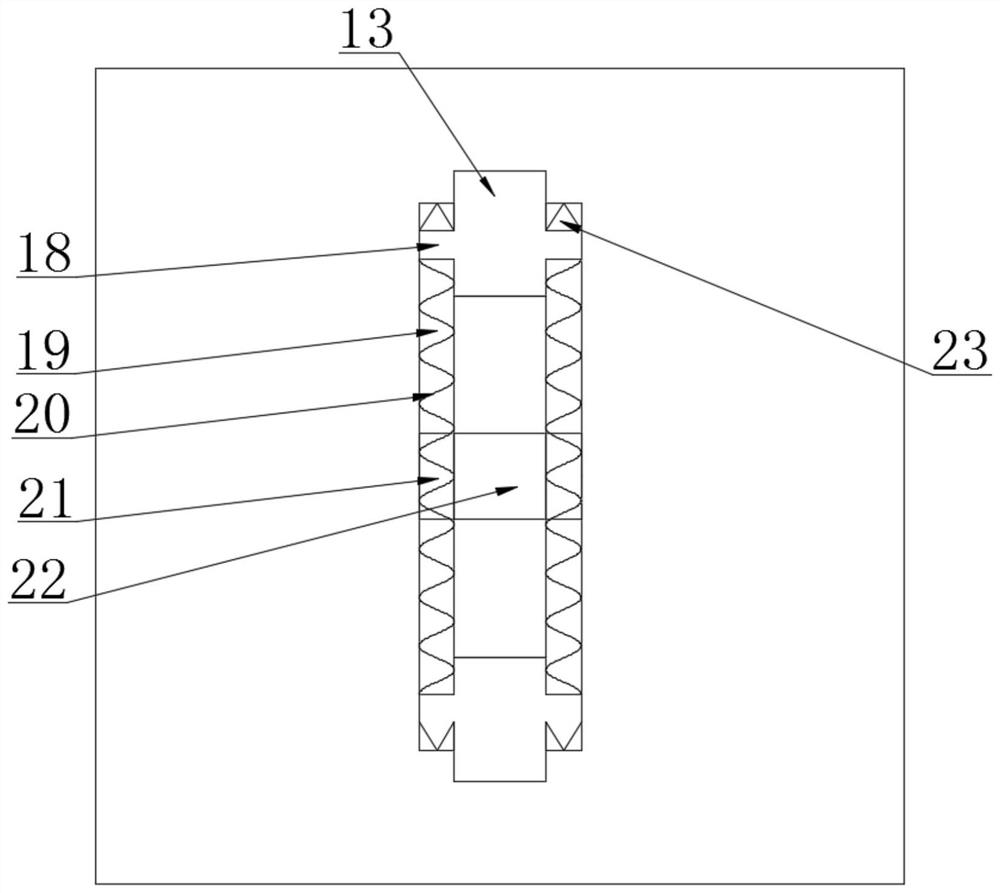

[0026] refer to Figure 1-9 , a detection device for power line fault monitoring equipment, including a cable 1, a connecting column 24 is installed on the bottom of the cable 1, a cutting ring 2 is installed on the surface of the connecting column 24, and the inside of the cutting ring 2 corresponds to the second moving block 10 The position of the second moving groove 11 is installed, the second moving block 10 matches the second moving groove 11, the second moving groove 11 and the cutting ring 2 are designed in one piece, and the cross-sectional shape of the second moving groove 11 is an arc shape, the axial cross-section shapes of the second moving block 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com