Drip irrigation corn width and narrow row no-tillage belt straw partition cleaning device group and cleaning method

A cleaning device and wide and narrow row technology, which is applied in the field of drip irrigation corn wide and narrow row no-tillage belt straw partition cleaning device, can solve the problems of poor fluidity of straw, affecting the passability of sowing machines and sowing quality, and small space between weeding wheels. Achieve the effects of fluidity avoidance, improvement of cleaning quality and machine passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

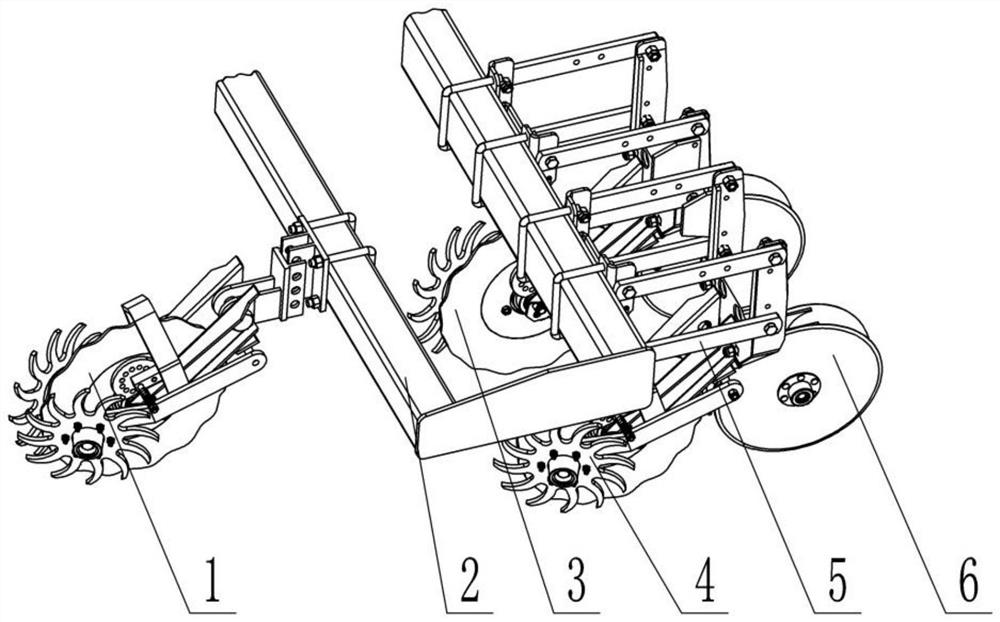

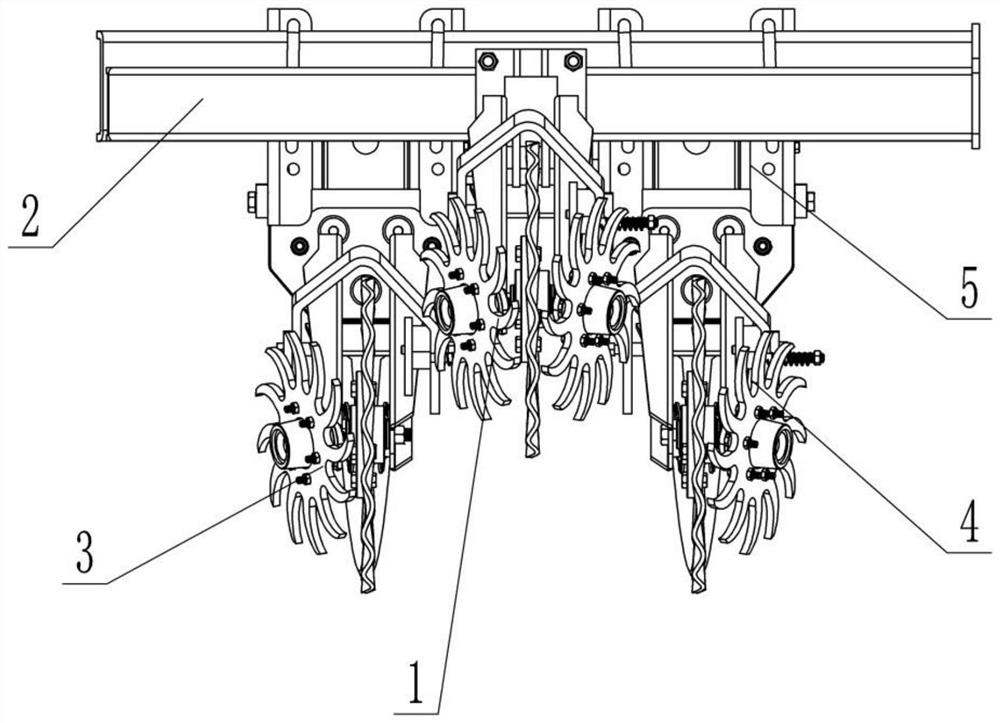

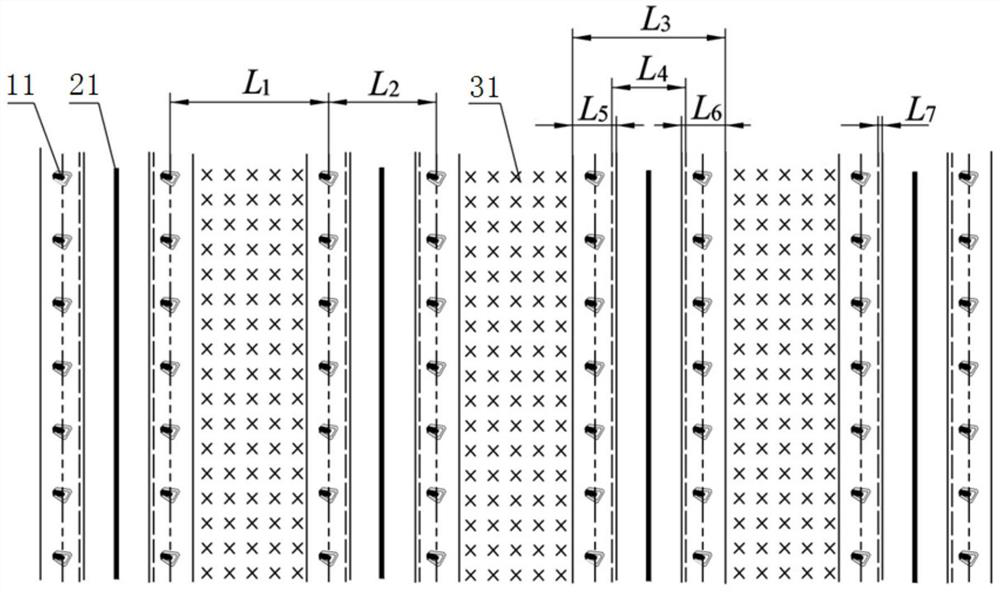

[0028] like figure 1 and figure 2 In the illustrated embodiment of the present invention, a group of cleaning devices includes: a double-sided weeding mechanism 1, a frame 2, a single right-side weeding mechanism 3, a single left-side weeding mechanism 4, a four-bar profiling mechanism 5 and a ditch. Device 6, wherein the double-sided weeding mechanism 1 is arranged in front of the frame 2, and the single right-side weeding mechanism 3 and the single left-side weeding mechanism 4 are both arranged at the rear of the frame 2 through a four-bar profiling mechanism 5, A trench opener 6 is provided behind the single right-side weeding mechanism 3 and the single left-side weeding mechanism 4, and the trencher 6 is also installed on the four-bar profiling mechanism 5;

[0029] The double-sided grass removal mechanism 1 includes a pair of claw wheels composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com