A turning fixture for thin-walled parts

A thin-walled parts, turning technology, applied in the direction of metal processing machinery parts, clamping, manufacturing tools, etc., can solve the problem that it is impossible to avoid the deformation of the processed parts, it is impossible to achieve the processing accuracy, and it is not easy to ensure the perfect processing parts and positioning blocks Contact and other problems to achieve the effect of eliminating vibration and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

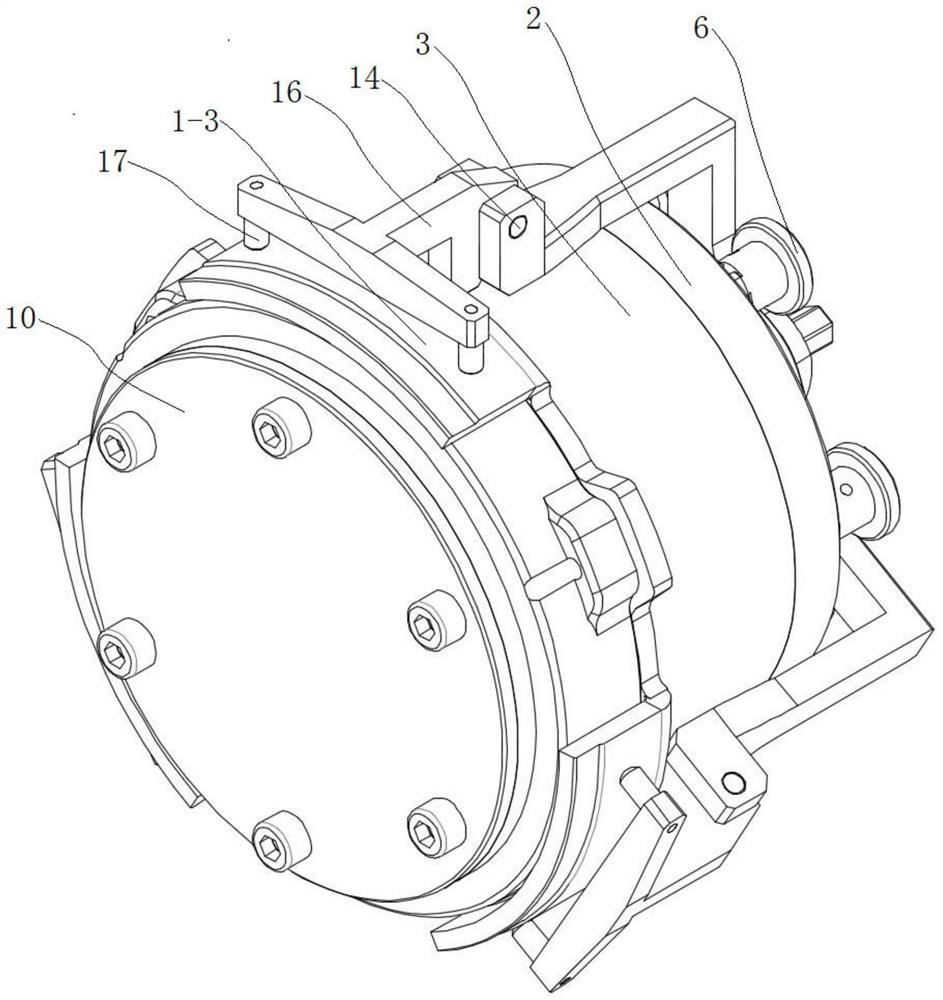

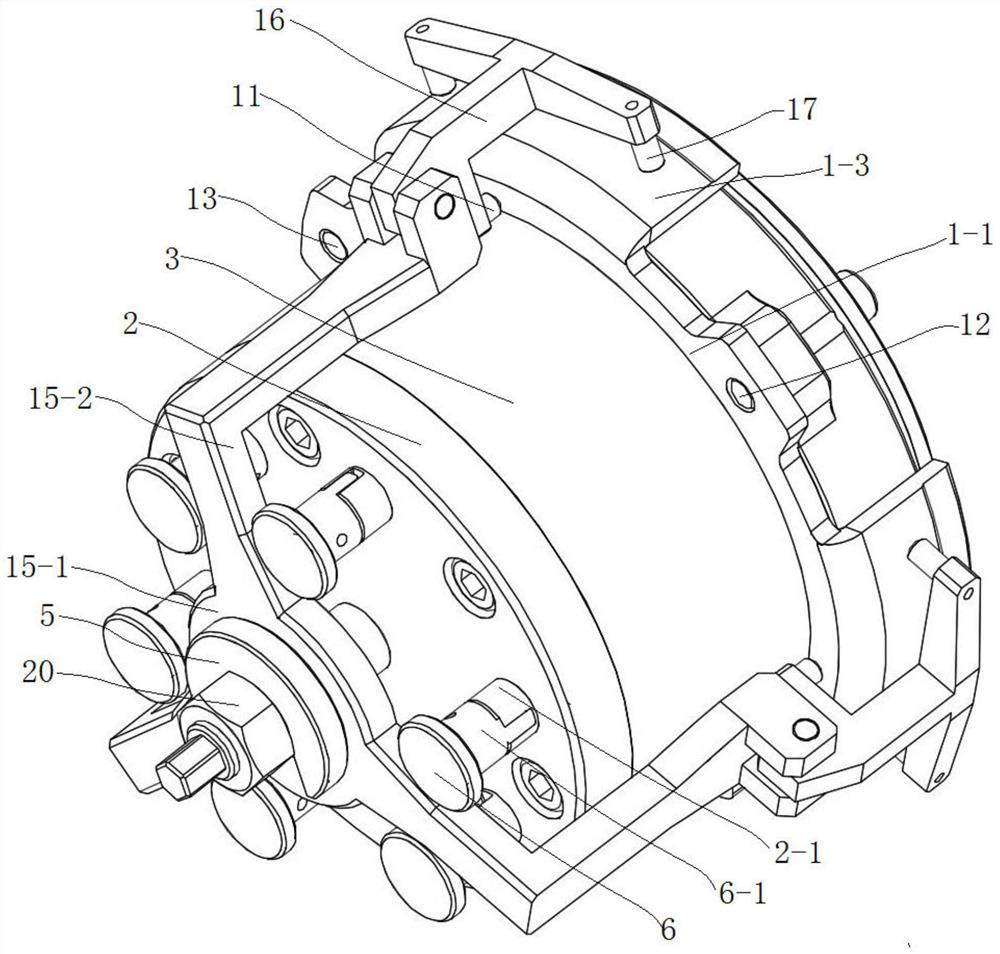

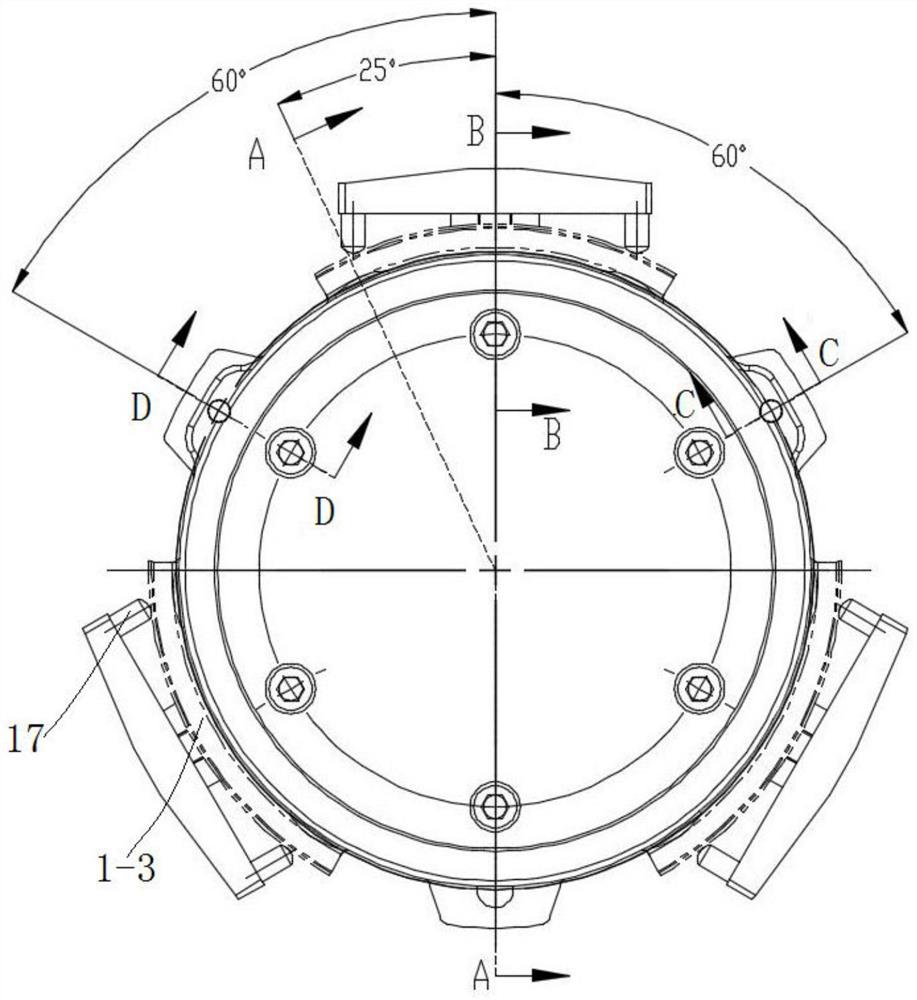

[0038] combine figure 1 , figure 2 and Figure 9, a kind of thin-walled part turning jig of the present embodiment comprises a cylindrical clamping body, and the clamping body includes a middle clamping body 3, a rear cover plate 2 fixed on the rear end surface of the middle clamping body 3, and a rear cover plate 2 fixed on the middle clamping body 3 The front cover plate 10 of the front end face, a step surface 3-1 is provided between the front outer peripheral surface of the intermediate folder body 3 and the rear outer peripheral surface of the intermediate folder body 3, and a cylindrical positioning cylinder is arranged on the stepped surface 3-1. Pin 13 and diamond-shaped positioning pin 12; after the front part of the middle clamp body 3 passes through the annular chassis 1-1 of the thin-walled part to be processed, the annular chassis 1-1 is matched with the stepped surface 3-1, and the stepped surface 3-1 Cylindrical locating pin 13 and rhombus locating pin 12 are...

Embodiment 2

[0050] The basic structure of a thin-walled part turning jig of this embodiment is the same as that of Embodiment 1, except that the angle between the first wedge surface and the axis of the cylindrical connecting portion is 8°.

Embodiment 3

[0052] The basic structure of a thin-walled part turning jig of this embodiment is the same as that of Embodiment 1, except that the angle between the first wedge surface and the axis of the cylindrical connecting portion is 10°.

[0053] The thin-walled part turning fixture of the present invention has simple structure, ingenious design, and convenient connection, and can well solve the positioning or clamping of the thin-walled part to be processed and the deformation during processing, thereby ensuring the accuracy of the thin-walled part to be processed Machining accuracy requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com