Operation platform for medical equipment maintenance

A technology for operating platforms and medical equipment, applied to workbenches, manufacturing tools, etc., can solve the problems of inconvenient disassembly and low fixation efficiency of medical equipment, and achieve the effects of saving time for loading and unloading medical equipment, increasing the amount of maintenance, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

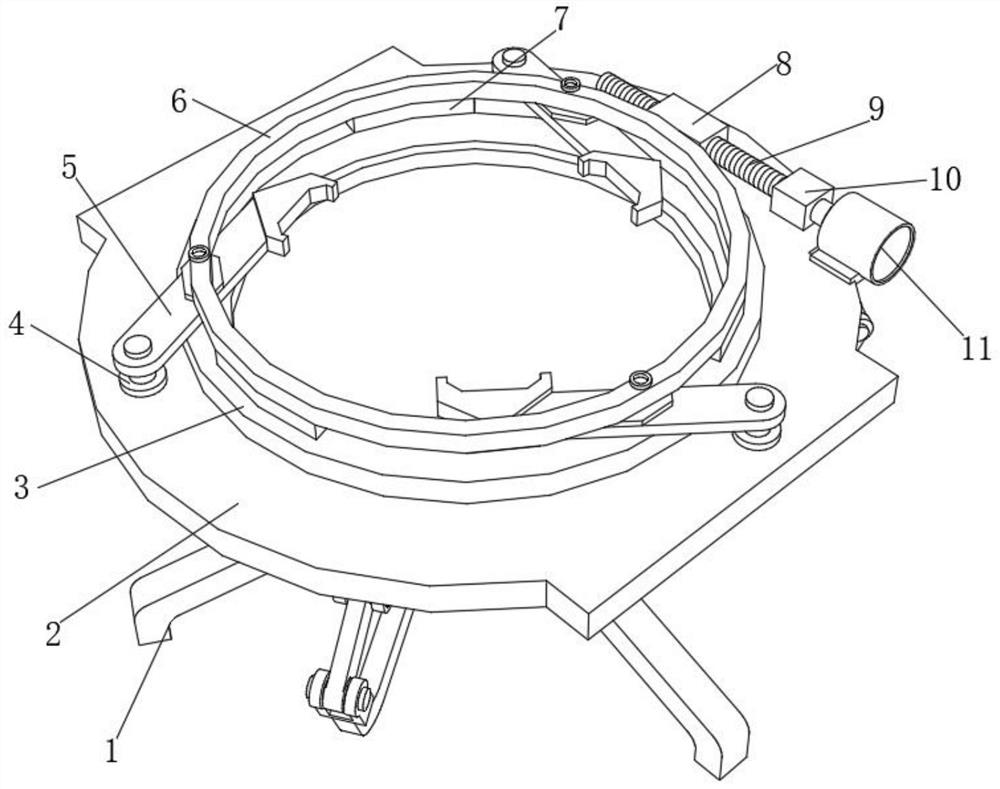

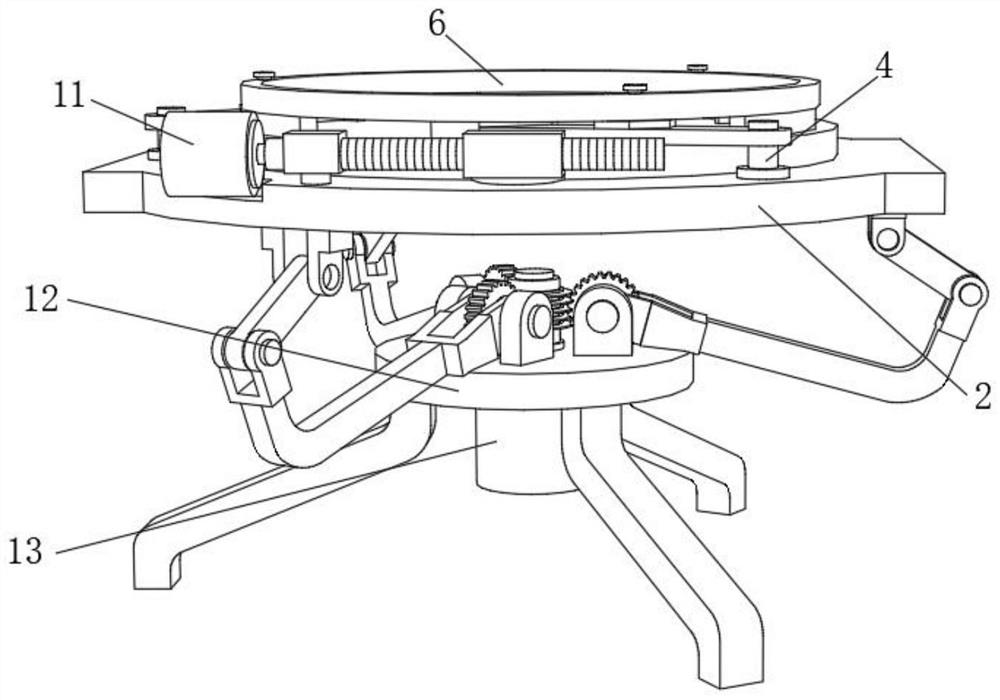

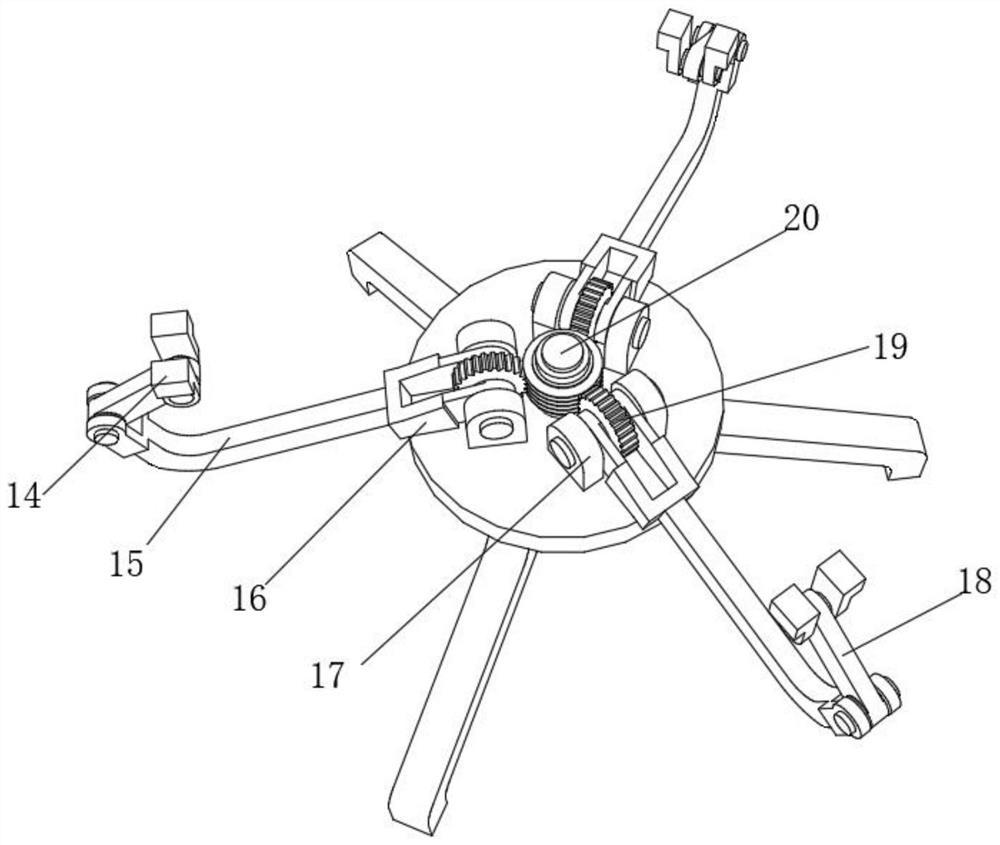

[0031] An operating platform for medical equipment maintenance, such as Figure 1-5 As shown, a top plate 2 is included, the bottom outer wall of the top plate 2 is provided with a lifting mechanism, and one side outer wall of the lifting mechanism is provided with three supporting legs 1, and the top side outer wall of the top plate 2 is fixed with a motor 11 through a support plate, and the motor The output end of 11 is threadedly connected with screw rod 9, and the peripheral outer wall of screw rod 9 near the side of motor 11 is sleeved with rotating block 10, and the bottom outer wall rotating shaft of rotating block 10 is connected with the top of top plate 2, and the peripheral outer wall of screw rod 9 covers A fixed block 8 is connected, the top outer wall of the top plate 2 is provided with a rotating groove, and the inner wall of the rotating groove is rotatably connected with a rotating bottom ring 3, one side of the fixed block 8 is welded to one side of the rotati...

Embodiment 2

[0035] An operating platform for medical equipment maintenance, such as Figure 5 As shown, in order to ensure the fixing effect of the medical equipment; this embodiment makes the following improvements on the basis of Embodiment 1: one end of the guide plate 5 is fixed with a U-shaped fixing block 25 by bolts, and the two sides of the U-shaped fixing block 25 The inner side is fixed with a circular fixed ring 26 by fastening bolts 27, and one side of the circular fixed ring 26 is provided with a plane structure; through the replacement of the circular fixed ring 26 to the triangular limit plate 21, the circular fixed ring can be effectively adjusted The angle of 26 makes its planar structure clamp the outer surface of medical equipment, which effectively meets the clamping requirements of irregular equipment, and also strengthens the fixing effect of medical equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com