Construction method of a prefabricated floor slab

A construction method and prefabricated technology, applied to floors, manufacturing tools, building components, etc., can solve problems such as increased construction costs and construction procedures, inability to play the role of tensioned steel bars, and easy cracking of concrete, so as to achieve simple structure and low cost. Engineering cost, the effect of ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

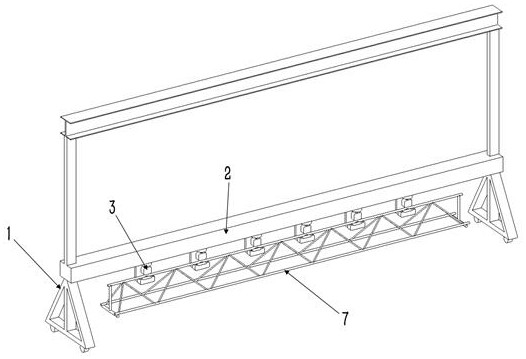

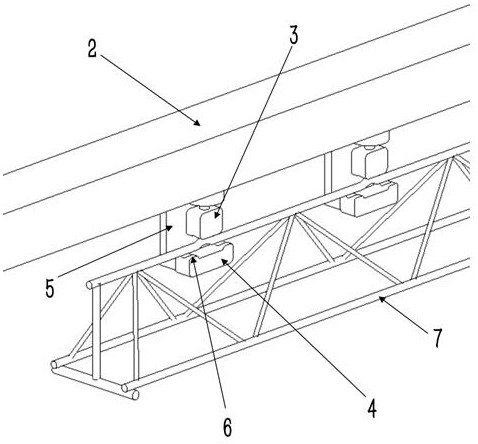

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] 1. A construction method for a prefabricated floor, comprising the following steps:

[0027] 1) Process corrugated steel bars: process several steel bars that bend in the same direction and protrude to form arc-shaped arches;

[0028] 2) Process the corrugated steel truss: use the corrugated steel bar prepared in step 1) as the upper chord steel bar, and weld it together with the web bar and the lower chord steel bar to form the corrugated steel truss 7; wherein, the arc-shaped arch faces The upper side of the corrugated steel truss;

[0029] 3) The lower chord reinforcement of the corrugated steel truss is prefabricated and connected with the bottom plate to form a reinforced truss floor deck;

[0030] 4) Use a straightening device to straighten the arc-shaped arch on the upper chord steel bar of the corrugated steel truss, so that the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com