Building cross beam assembly structure with prefabricated assembly type foundation

A technology of prefabricated assembly and assembly structures, which is applied in basic structure engineering, building construction, construction, etc. It can solve the problems of increased beam weight, external force buffering, and inconvenient assembly, so as to improve assembly efficiency, good external force buffering, and increase stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

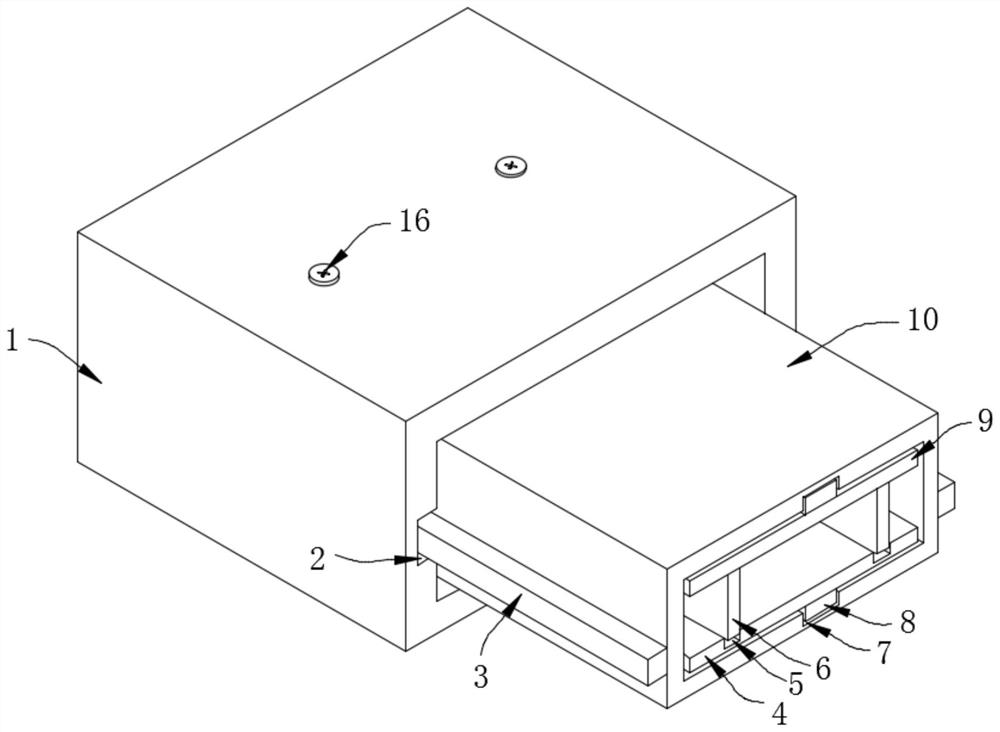

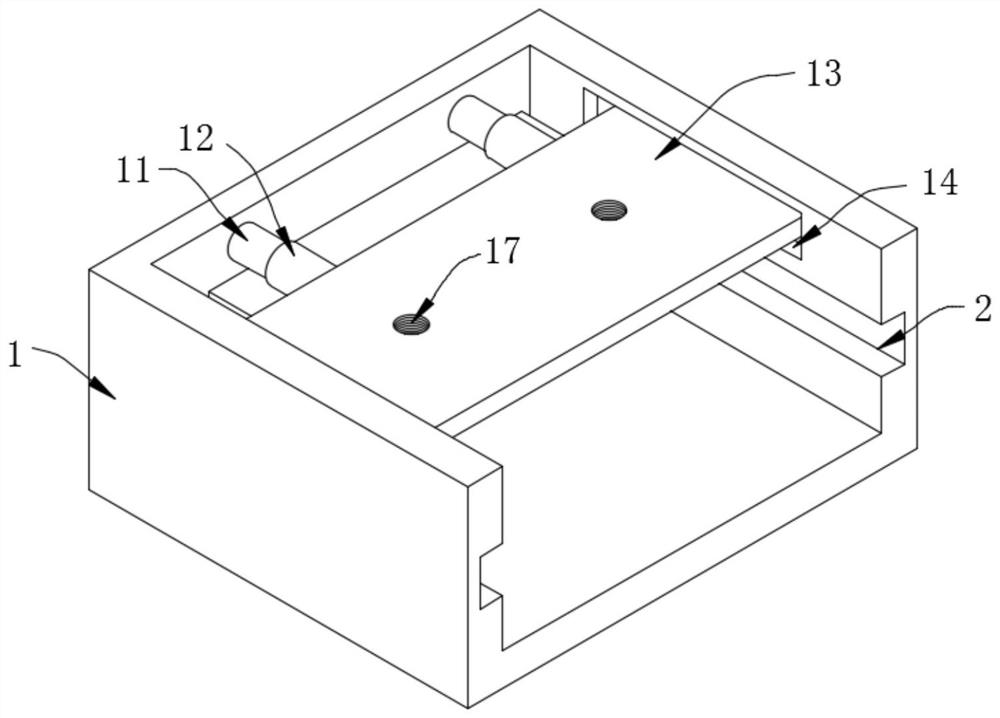

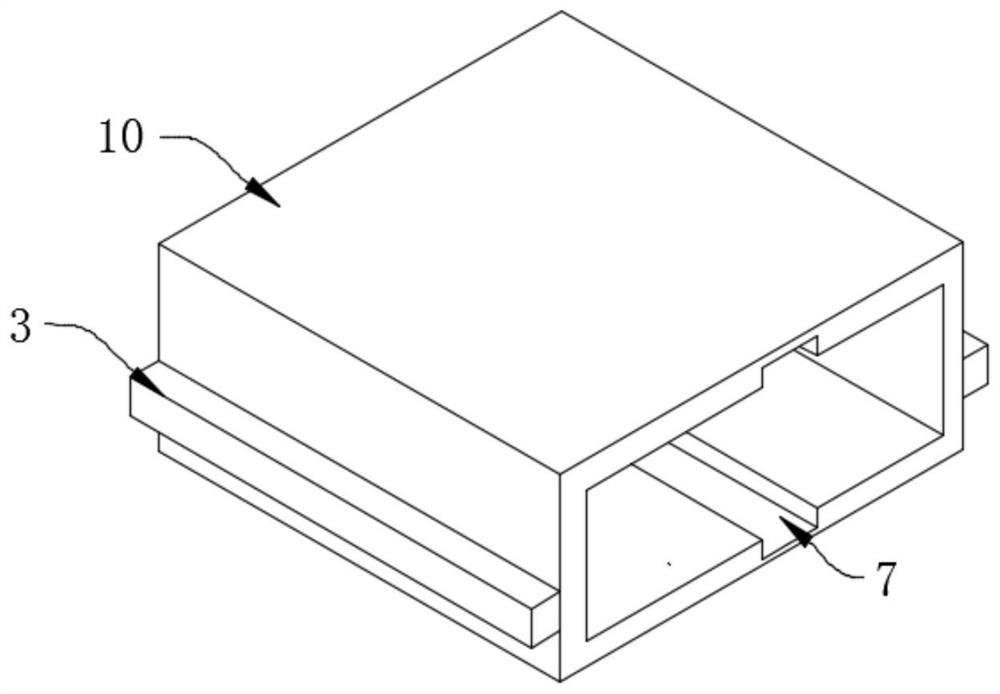

[0026] see Figure 1-6 , the present invention provides a technical solution: a building beam assembly structure with a prefabricated assembly type foundation, including a fixed shell 1, the inside of the fixed shell 1 is slidably connected with a support shell 10, and the inner top wall of the support shell 10 The third support plate 9 is slidably connected, the inner bottom wall of the support housing 10 is slidably connected with the first support plate 4, the lower surface of the third support plate 9 is provided with a fourth chute 23, and the inside of the fourth chute 23 is symmetrical. Two second sliders 22 are slidably connected, the lower surfaces of the two second sliders 22 are hinged with a hinged plate 24, the lower surface of the hinged plate 24 is hinged with a first slider 20, and the upper surface of the first support plate 4 is hinged. Two fifth sliding grooves 26 are symmetrically opened, and the first sliding block 20 is slidably connected to the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com