Inclined shaft feeding and discharging and single transverse channel combined highway tunnel ventilation system and method

A technology for highway tunnels and ventilation systems, which is used in mine/tunnel ventilation, earth-moving drilling, mining equipment, etc., can solve the problems of insignificant reduction in energy consumption, large investment in ventilation and civil engineering, and large configuration of mechanical and electrical equipment. The effect of improving ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

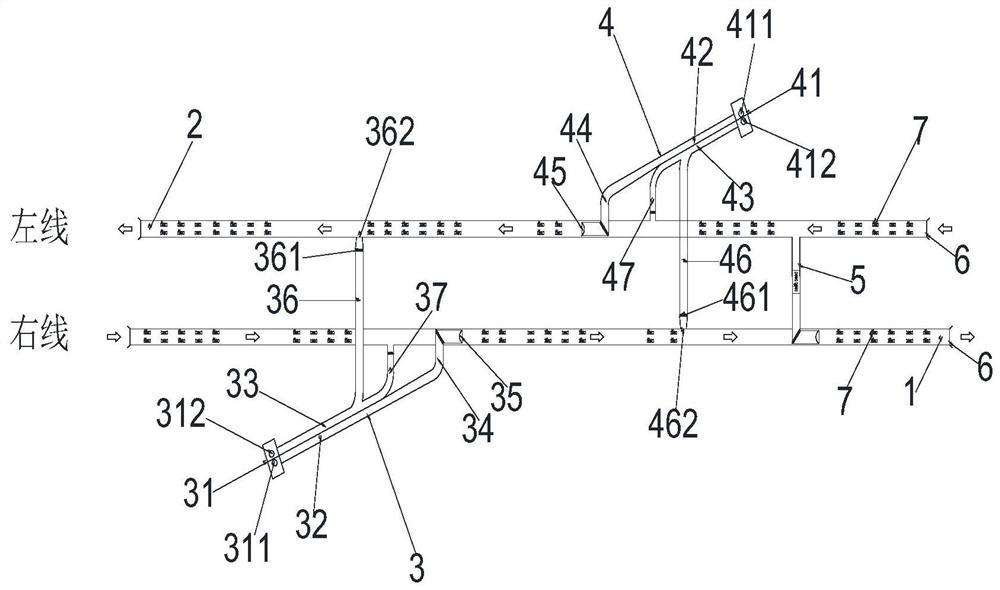

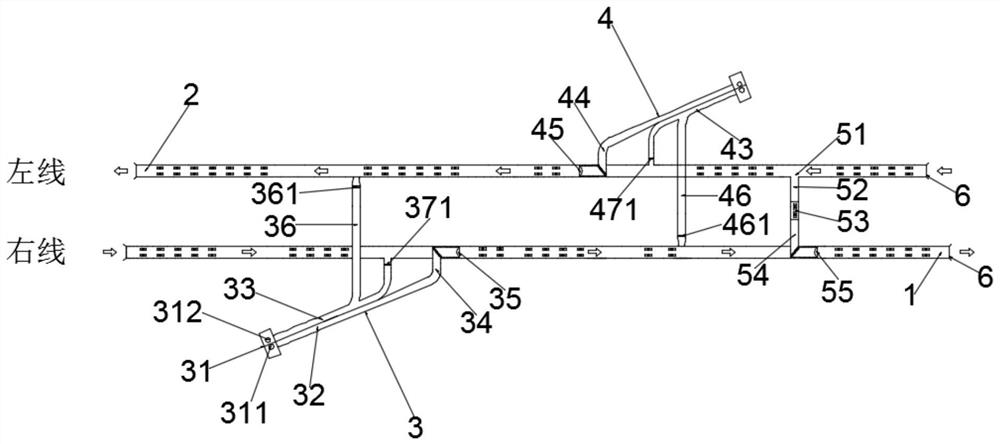

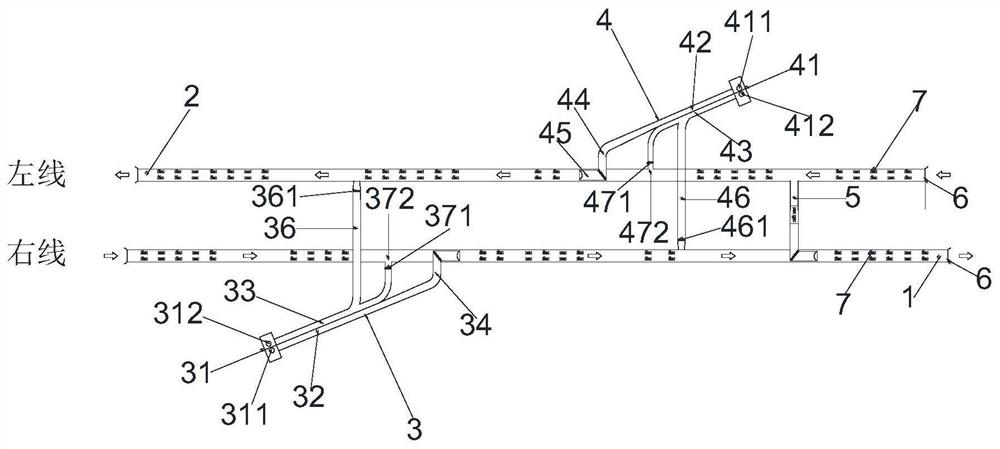

[0072] Such as figure 1 , figure 2 and image 3As shown, the present invention is a highway tunnel ventilation system combined with inclined shaft delivery and single transverse channel, including right line tunnel 1, left line tunnel 2, right line ventilation inclined shaft 3 and left line ventilation inclined shaft 4, right line ventilation The inclined shaft 3 is installed in the right-line tunnel 1, the left-line ventilation inclined shaft 4 is installed in the left-line tunnel 2, the right-line ventilation inclined shaft 3 is set opposite to the left-line ventilation inclined shaft 4; the right-line ventilation inclined shaft 3 includes the right-line inclined shaft Fan room 31, main air duct on the right line, air supply duct 34 at the bottom of the right line, exhaust duct 37 at the bottom of the right line, and flue exhaust duct 36 on the right line. The other end is respectively connected to the air supply duct 34 at the bottom of the right line, the exhaust duct 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com