Goaf filling space detection method under coal mine fully mechanized caving mining process condition

A technology of process conditions and space filling, which is applied in the direction of electrical/magnetic detection, electrical/magnetic exploration, and measuring devices for well logging records. It can solve the problems of high detection accuracy and inaccessibility, and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be further described in detail below in conjunction with specific embodiments, which are for explanation rather than limitation of the present invention.

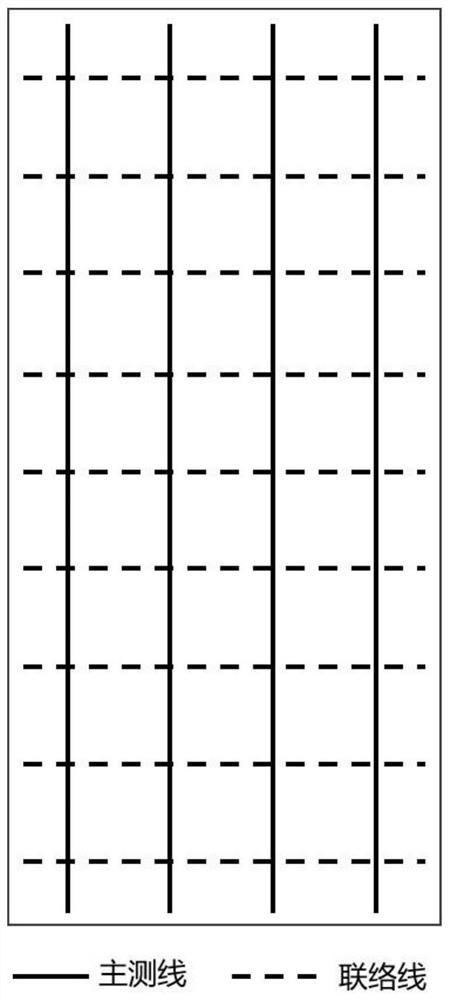

[0029]The basic principle of the detection method of the present invention is the geophysical electric magnetic exploration method, combined with the difference in the vertical detection depth between the high-density electric method and the transient electromagnetic method, and the combined apparent resistivity inversion method Vertical classification detection of the filling space reveals the size and distribution of the voids and cracks in the caving zone and the fracture zone of the goaf that can be used for the gangue particle-level filling, so as to solve the filling space of the goaf under the condition of fully mechanized coal caving technology Problems that are difficult to quantitatively estimate, improve detection accuracy. The detection method of the present invention takes into account t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com