Job-shop scheduling method with cache constraints based on improved genetic algorithm

An improved genetic algorithm and job shop technology, applied in the field of job shop scheduling with cache constraints, can solve problems such as little research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

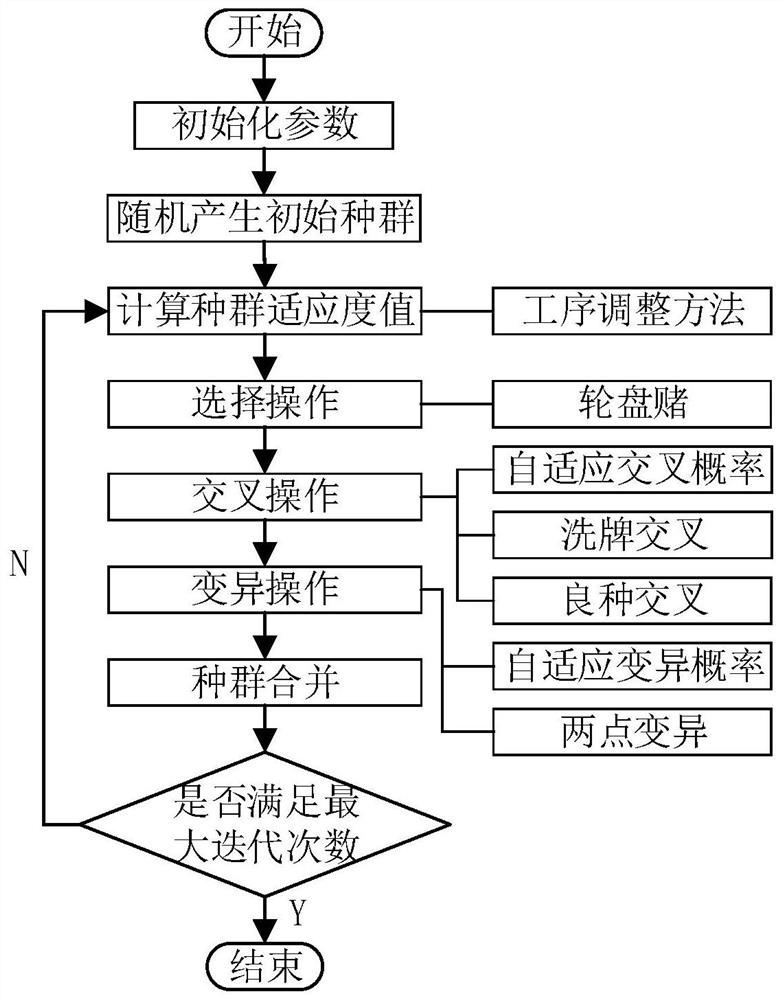

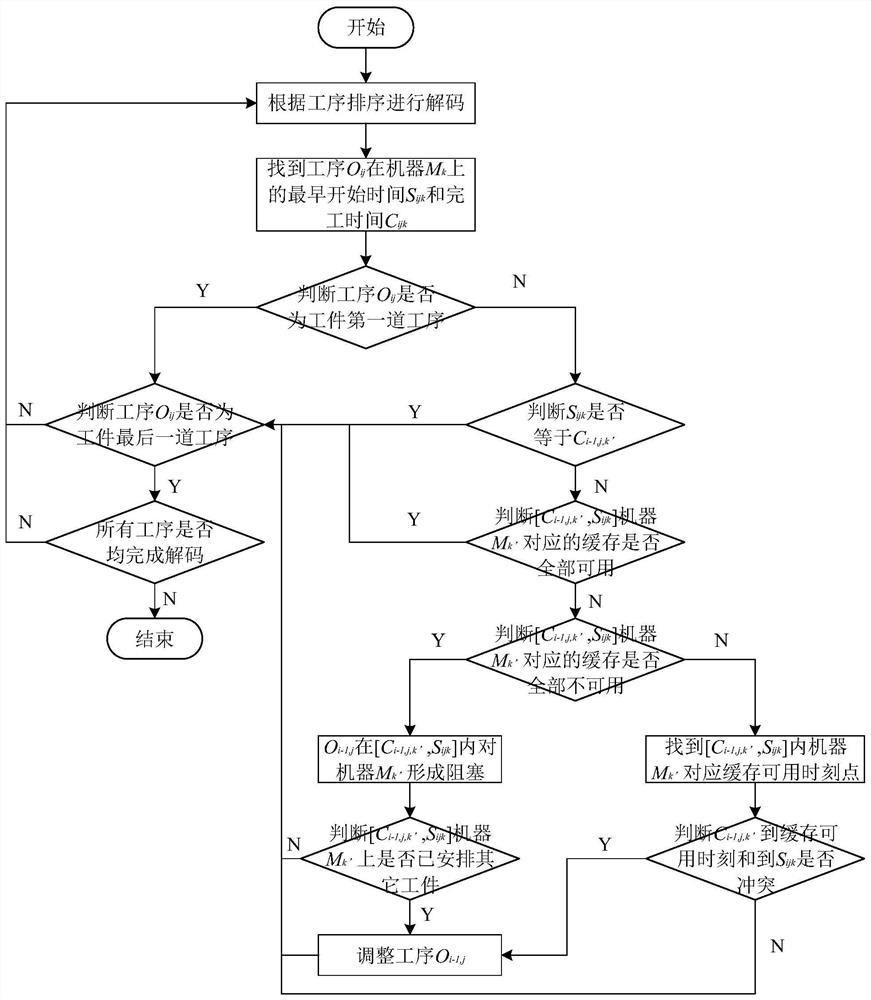

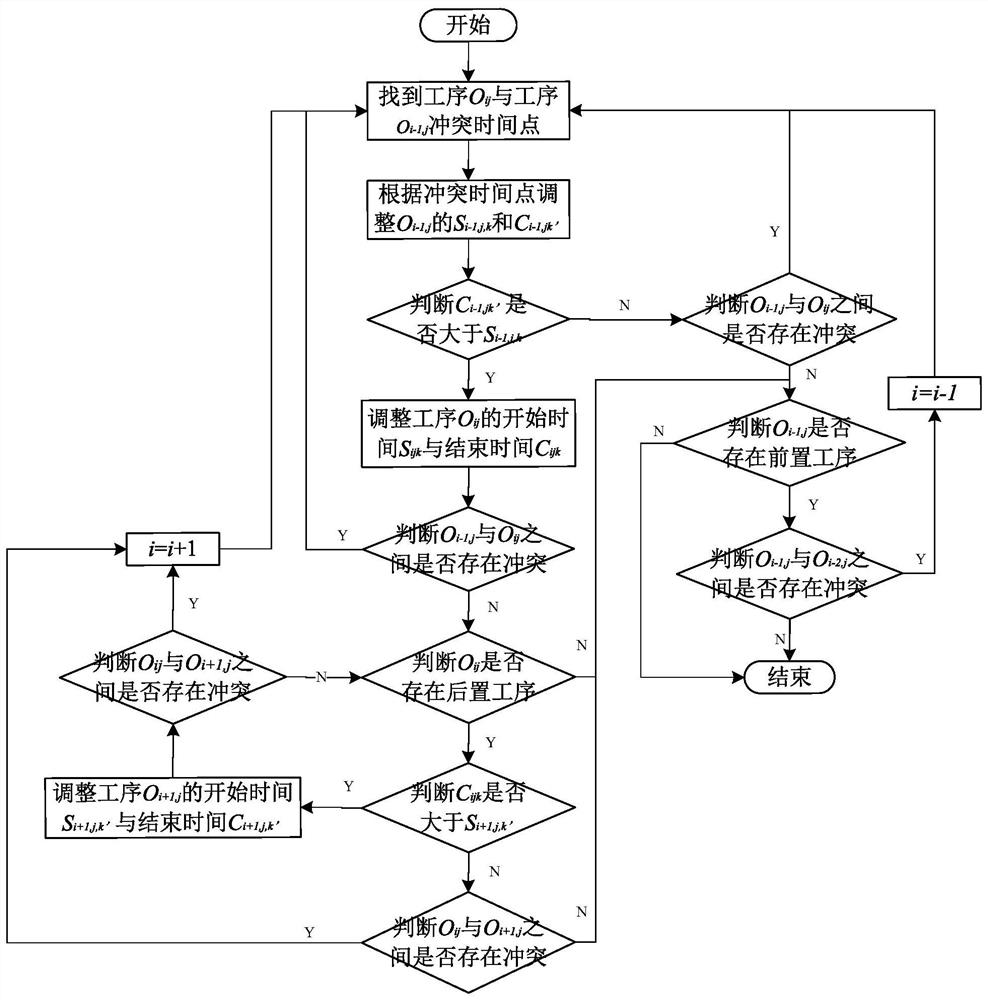

Method used

Image

Examples

Embodiment

[0117] The present invention selects a standard job shop benchmark example to test the performance of the algorithm. Based on the standard calculation examples La01~La20, the percentage of the machine cache capacity and the number of processed workpieces is constructed. For example, the scale of the calculation example La01 is 10x5, indicating that the number of workpieces is 10 and the number of machines is 5; the percentage of the machine cache capacity and the number of processed workpieces is 10 %, it means that the cache capacity of each machine is 1.

[0118] (1) Experimental parameter settings

[0119] The initial population size, cross-mutation probability, and number of iterations of the improved genetic algorithm will all affect the convergence of the algorithm. In this paper, the population size is set at 50-200, and the number of iterations is 50-200 for multiple experimental comparisons. When the population size PopSize=100 , The convergence of the algorithm is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com