A crushing and screening integrated device and operation method for road and bridge construction

A crushing shaft and crushing knife technology, applied in chemical instruments and methods, roads, bridges, etc., can solve the problems of wasting time, wasting manpower, reducing the processing speed of materials, etc., achieve good separation effect, save time, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

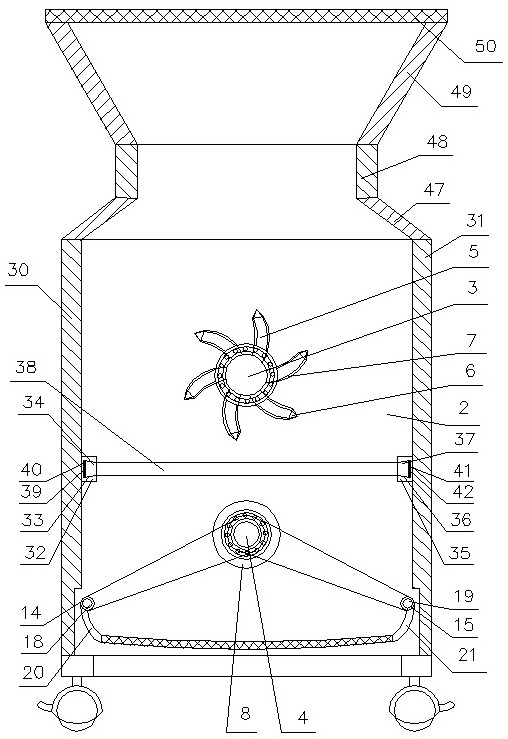

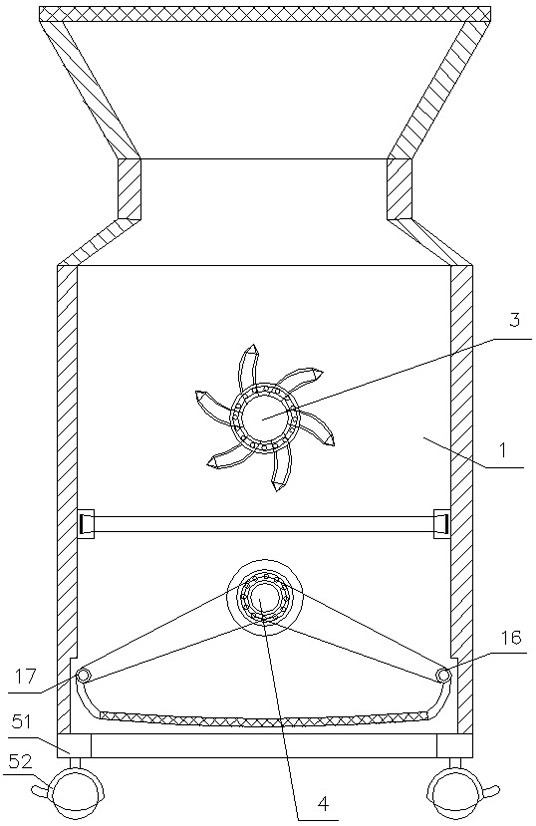

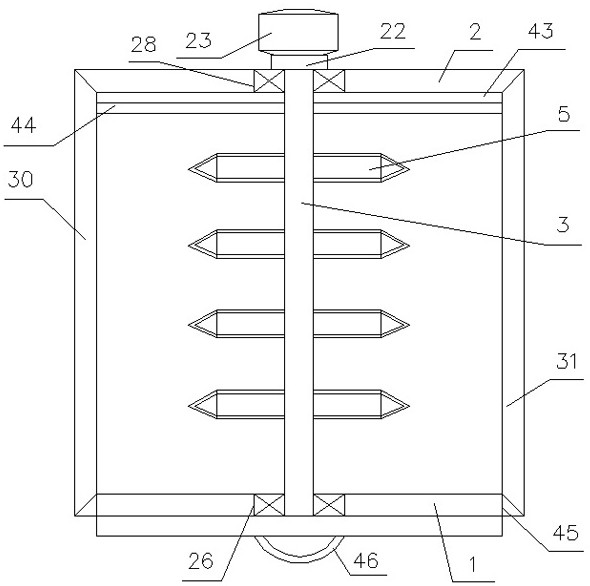

Embodiment 1

[0025] A crushing and screening integrated device for road and bridge construction, its composition comprises: outer box body, described outer box body has front box board 1 and rear box board 2, described front box board and described back box An upper crushing shaft 3 and a lower crushing shaft 4 are arranged between the plates. The upper crushing shaft is connected with a group of crushing knives 5 around the circumference. It is a triangle 6, and the top, bottom, and triangle of the crushing knife have cutting edges 7, the cutting edges are distributed comprehensively, and the effect of crushing is good, and the lower crushing shaft is connected to a set of crushing circular saw blades 8 arranged horizontally The crushing circular saw blade has a flat cutting edge, which can cut and crush raw materials. The lower crushing shaft is connected to the front left pulley 9, the front right pulley 10, the rear left pulley 11, and the rear right pulley 12. The front left pulley pas...

Embodiment 2

[0027] In the integrated crushing and screening device for road and bridge construction described in Embodiment 1, the upper crushing shaft is connected to an upper coupling 22, and the upper coupling is connected to a motor 23, and the motor can drive the upper crushing shaft to rotate , and then can drive the pulverizer to rotate, and the pulverized raw materials are uniform and thorough. The lower pulverization shaft is connected to the lower coupling 24, and the lower coupling is connected to the forward and reverse motor 25. The motor is connected to the positive and negative The rotating machines are all located outside the outer box.

Embodiment 3

[0029] A crushing and screening integrated device for road and bridge construction described in Example 1, the front box plate is provided with a front upper circular hole 25 and a front lower circular hole 26, and the rear box plate is provided with a rear upper circular hole hole 27 and the rear lower round hole 28, the front upper round hole is connected to the front end of the upper pulverizing shaft through a bearing 29, and the front lower round hole is connected to the front end of the lower pulverizing shaft through a bearing. The rear upper round hole is connected to the rear end of the upper crushing shaft through a bearing, and the rear lower round hole is connected to the rear end of the lower crushing shaft through a bearing.

[0030] The front upper round hole and the rear upper round hole not only have the function of supporting the upper crushing shaft but also have the function of positioning the upper crushing shaft; The role of the axis. The bearing makes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com