Upper sleeping berth assembly of commercial truck

A truck and commercial technology, applied in the field of vehicle interiors, can solve problems such as insufficient rest width, and achieve the effect of improving rest comfort and reducing sleeper width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings. The embodiments of the present invention are exemplary and should not be construed as limitations on the present invention. Those skilled in the art may make changes, modifications, substitutions and modifications to the above embodiments within the scope of the present invention.

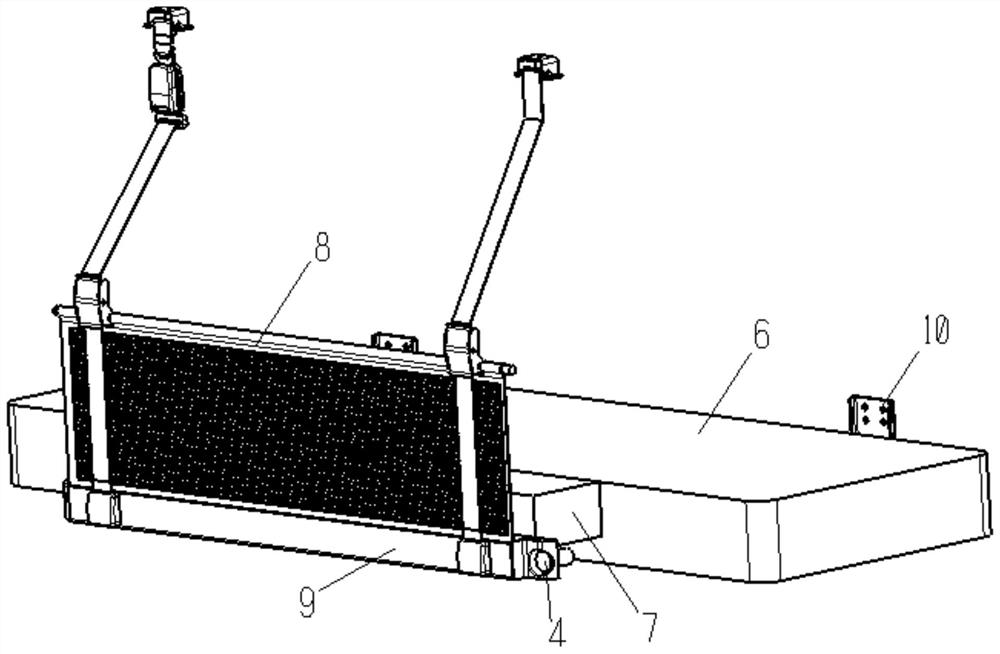

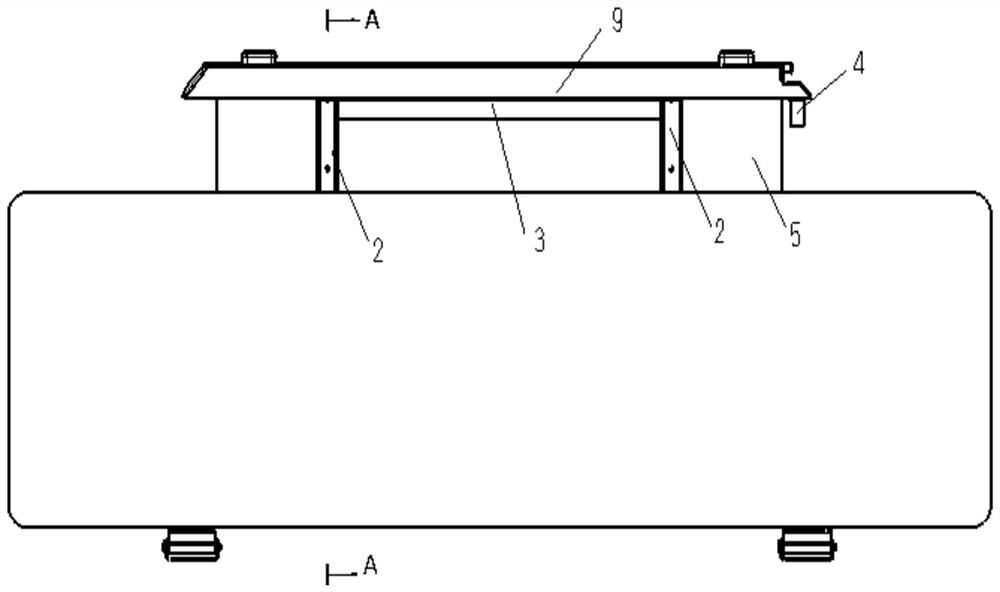

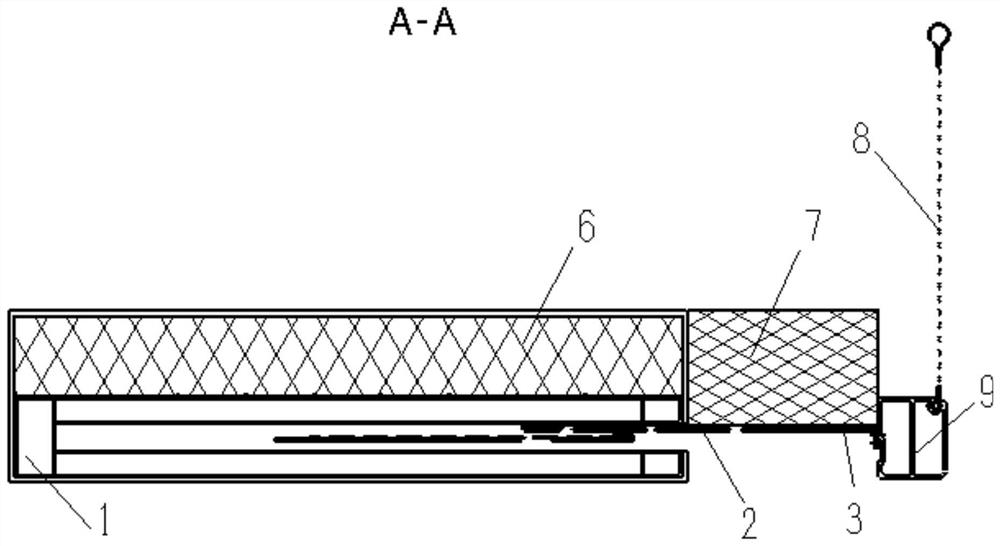

[0020] Such as Figure 1-3 As shown, the present invention provides a sleeper assembly on a commercial truck, comprising a hollow bearing frame 1, more than two adjustment slide rails 2, slide rail connecting plates 3, soft connection structures 5, main bedding 6, protection mechanisms 8, The front aluminum alloy rod 9 and the rear hinge 10; the adjustment slide rail 2 is fixed on the upper inner surface of the bearing frame 1, and the two adjacent adjustment slide rails 2 are connected by the slide rail connecting plate 3 , the end of the slide rail connecting plate 3 away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com