Novel anti-windage heavy hammer sheet and anti-windage heavy hammer device

A technology of heavy hammers and hammers, which is applied in the field of new windproof eccentric hammers and windproof eccentric hammer devices, which can solve problems such as poor stability, inconvenient installation of suspension weights, and fatigue damage of line fittings, so as to achieve rapid absorption and prevent wind deflection flashover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

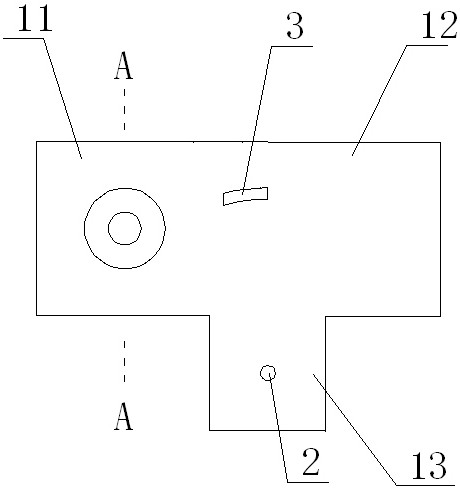

[0030] Such as Figure 1 to Figure 2 As shown, this embodiment discloses a new type of windproof eccentric hammer, which includes a T-shaped heavy hammer body, the heavy hammer body is divided into a horizontal part and a vertical part 13, and the horizontal part is divided into the second part with the vertical part Half 11 and second half 12, wherein the horizontal length of the first half 11 is greater than the second half 12, so that the center of gravity of the weight sheet is set against the first half 11; the center of gravity of the weight sheet during installation Stay away from the side of the tower.

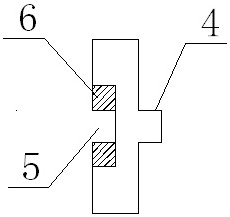

[0031] The hammer body is provided with a lower fixing hole 2 at the midline position of the vertical part, and an upper fixing hole 3 is arranged at a position corresponding to the lower fixing hole 2 on the horizontal part; wherein, the lower fixing hole 2 is a round hole, and the upper fixing hole 3 is The lower end fixing hole 2 is an arc-shaped long hole with the...

Embodiment 2

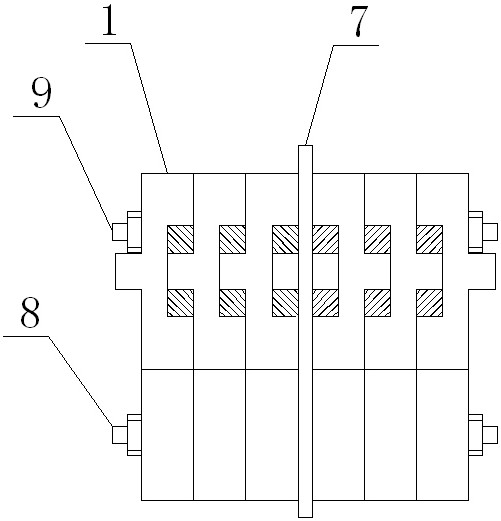

[0036] Such as image 3 As shown, this embodiment discloses a windproof eccentric weight hammer device, which includes the new windproof eccentric weight hammer 1 described in Embodiment 1, and also includes a connecting plate 7. The wires pass through the reserved holes around the connecting plate 7, and the connecting plate The two sides of 7 are symmetrically stacked with the new windproof eccentric hammer 1, and the lower connecting rod 8 passes through the lower fixing hole 2, and the upper connecting rod 9 and the lower connecting rod 8 pass through the upper fixing hole 3. And upper connecting rod 9 is kept on the connecting plate 7 by the novel windproof bias weight hammer plate 1 on both sides of the connecting plate 7.

[0037] The novel windproof eccentric hammer disclosed by the invention is different from the traditional heavy hammer, and adopts an eccentric design. The center of gravity is away from the side of the tower body, and a moment is applied to the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com