Agricultural rapeseed rapid stripping device

A stripping device, rapeseed technology, applied in agriculture, agricultural machinery and implements, applications, etc., can solve the problems of inability to simultaneously achieve rapeseed screening, low efficiency, etc., to speed up the sweeping speed, improve work efficiency, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

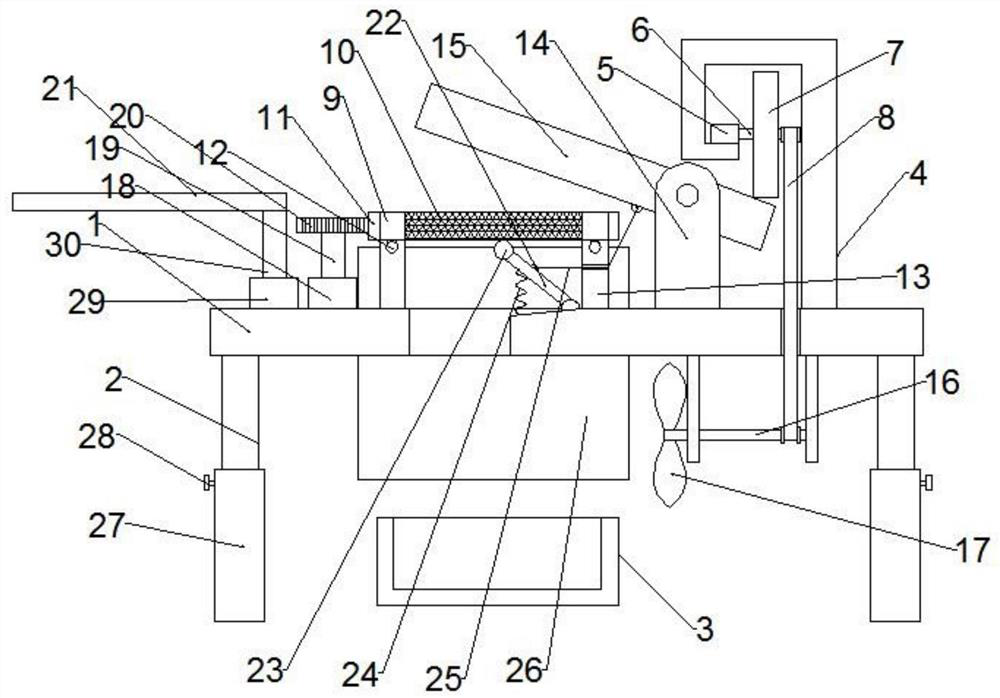

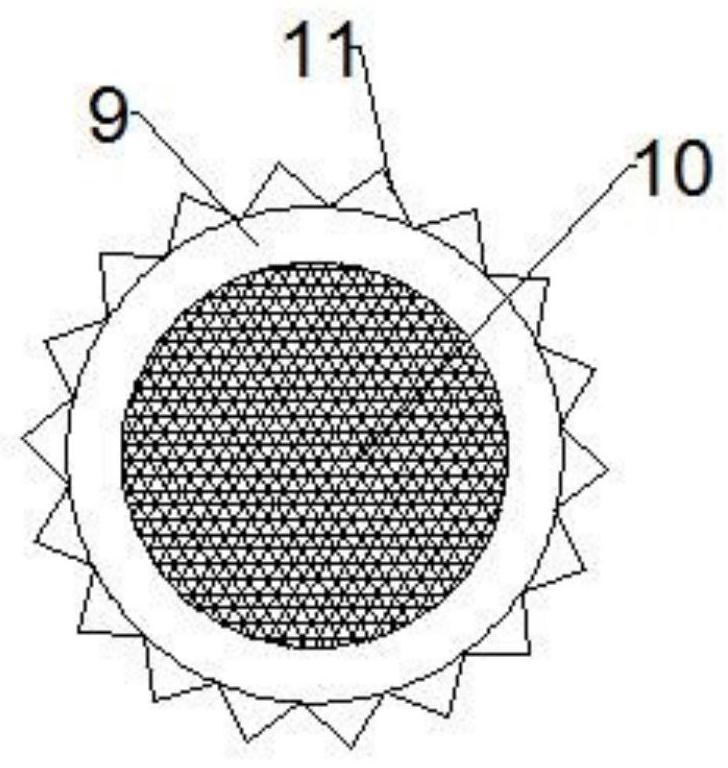

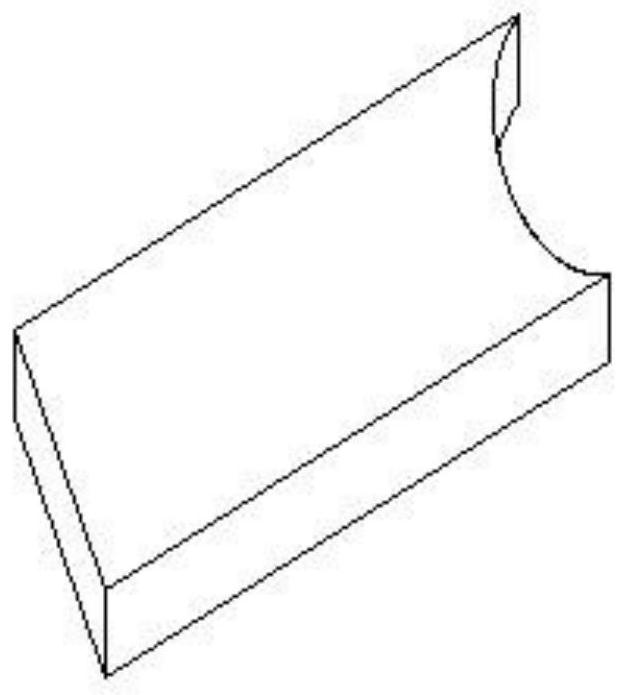

[0019] see Figure 1-3 , an agricultural rapeseed quick peeling device, comprising a base plate 1, a support rod 2 and a collection tank 3, the four corners of the bottom end of the base plate 1 are respectively fixed with support rods 2, and the collection tank 3 is located on the base plate 1 Below, the upper right side of the bottom plate 1 is fixed with a support frame 4, the support frame 4 is fixed with a first motor 5, and the output end of the first motor 5 is fixedly connected with a first rotating shaft 6, so The left fixed sleeve of the first rotating shaft 6 is provided with a cam 7, and the bottom of the cam 7 is pressed with a beating plate 15, and the beating plate 15 is rotated by the fixing seat 14 and is arranged above the support ring plate 9. The inner side of the ring plate 9 is fixed with a filter plate 10, and the bottom end of the support ring plate 9 is fixed with four sliders 12, which form a square between the sliders 12, and the sliders 12 are slida...

Embodiment 2

[0028] see Figure 1-3, this embodiment is further optimized on the basis of Embodiment 1. Specifically, a third motor 18 is fixedly installed on the left side of the upper end of the bottom plate 1, and the output end of the third motor 18 is fixedly connected to a first Four rotating shafts 19, a gear 20 is fixedly sleeved on the fourth rotating shaft 19, a gear ring 11 is fixed on the outside of the support ring plate 9, and the gear ring 11 meshes with the gear 20; the third motor 18 can drive the gear 20 to rotate through the fourth rotating shaft 19, and the gear 20 can further drive the support ring plate 9 to rotate through the gear ring 11, so that the rapeseed on the filter plate 10 can be evenly and fully Beating makes the rapeseed fully peel off, and at the same time makes the rotation direction of the filter plate 10 opposite to the rotation direction of the cleaning plate 21, which can speed up the cleaning speed of the straw at the upper end of the filter plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com