Meat protein production line for feed

A meat protein and production line technology, which is applied in the field of feed meat protein production line, can solve the problems of unsuitable production technology and achieve the effect of safe and high-quality feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

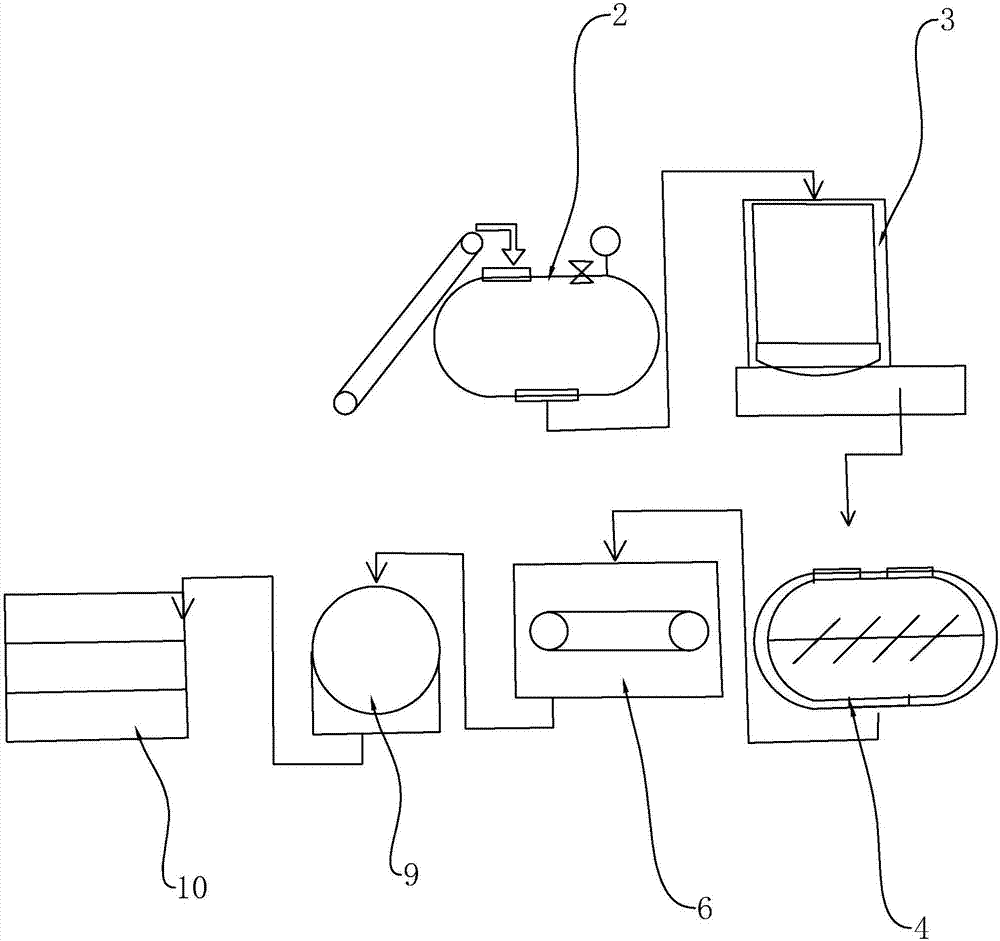

[0046] Such as figure 1 As shown, a meat protein production line for feed is characterized in that it includes a cooking tank 2, an oil press 3, a dryer, a cooler 6, a pulverizer 9 and a rotary screen 10 connected in sequence.

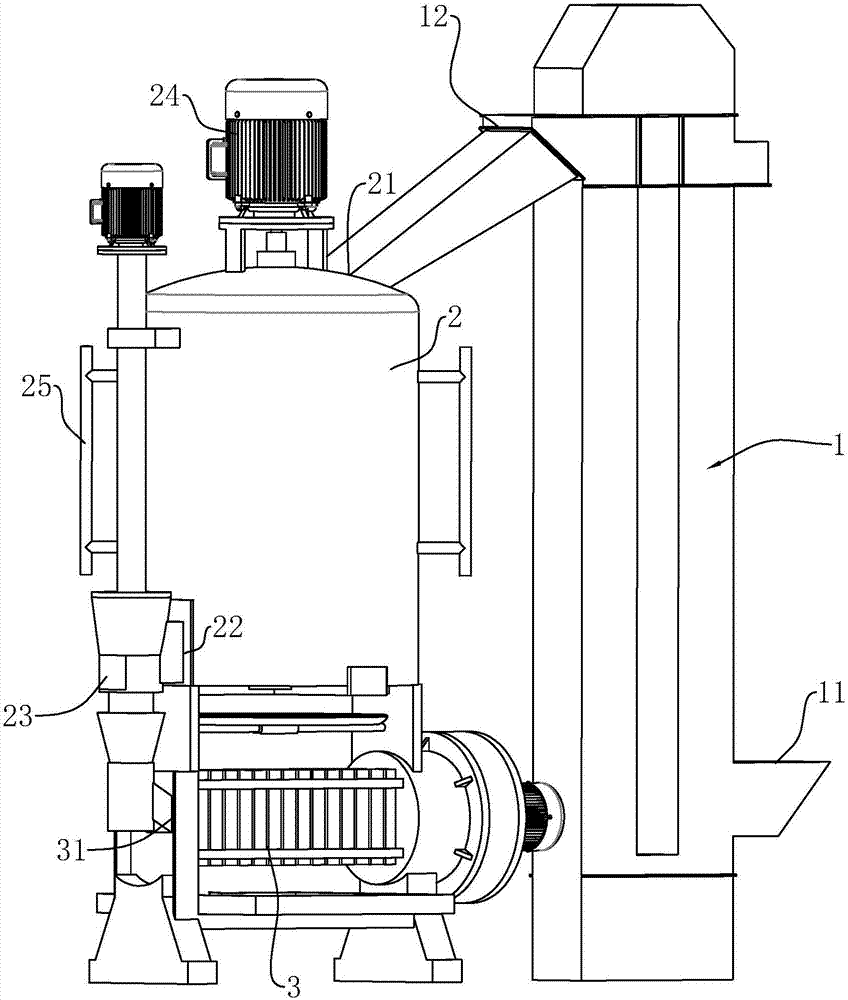

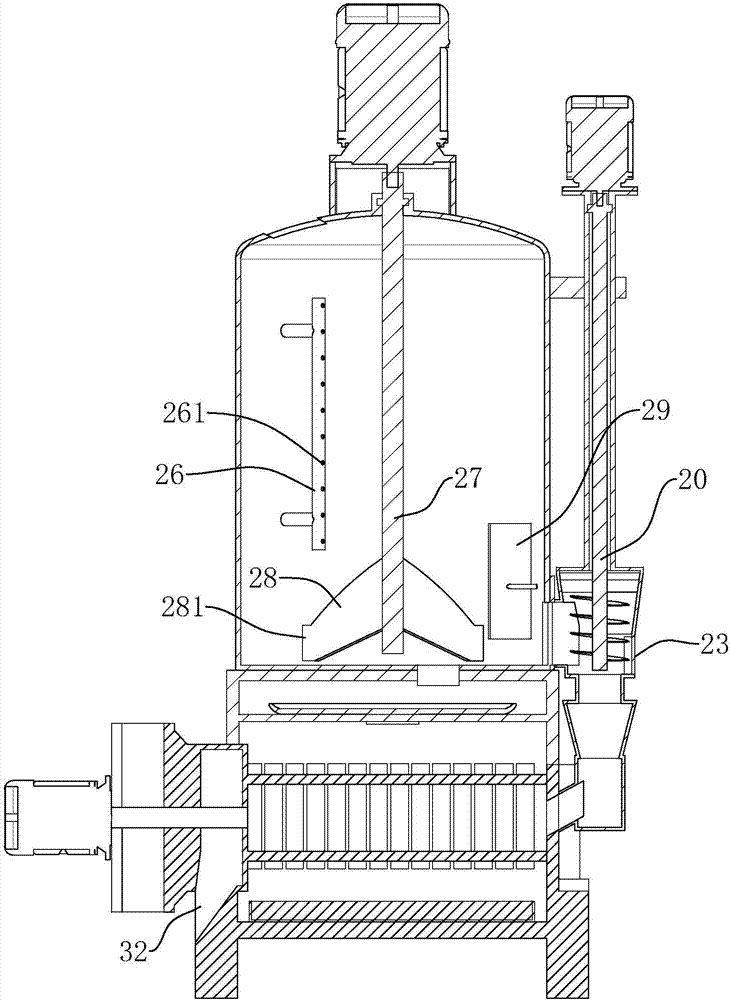

[0047] Such as figure 2 and 3 As shown, the side of the cooking tank 2 is provided with a hoist 74, the oil press 3 is located below the cooking tank 2, and the hoist 74, the cooking tank 2 and the oil press 3 are connected to each other.

[0048] Elevator 74 includes feeding inlet 11 and feeding outlet 12; cooking tank 2 includes raw material inlet 21 and raw material outlet 22; feeding inlet 11 of elevator 74 is connected with raw material inlet 21 of cooking tank 2, and oil press 3 includes a third feed Port 31 and the third discharge port 32, the raw material outlet 22 of the cooking tank 2 and the third feed of the oil press 3 are connected.

[0049] A steam pipe 26 is provided on the inner side wall of the cooking tank 2 , and a plurality of ...

Embodiment 2

[0078] Such as Figure 16 As shown, the difference from Embodiment 1 is that the helical blade 542 is divided into two sections, the left blade 5421 and the right blade 5422, which rotate in opposite directions. One end of the left blade 5421 and one end of the right blade 5422 are close to each other and both are located at the feed outlet 1063 below.

[0079] When the rotating shaft 109 rotates, the left blade 5421 and the right blade 5422 push the material away to the left and right sides respectively.

Embodiment 3

[0081] Such as Figure 17 As shown, the difference from the second embodiment is that a push pedal blade 543 is arranged between the left blade 5421 and the right blade 5422, and the push pedal blade 543 is also fixedly connected to the rotating shaft 109, and the push pedal blade 543 is in the shape of a plate. The section can be arc-shaped, and the bending direction of the push plate blade 543 is opposite to the rotation direction of the rotating shaft 109 . At the same time, a plurality of push plate blades 543 can be arranged on the rotating shaft 109 , and the plurality of push plate blades 543 are evenly distributed along the circumference of the rotating shaft 109 .

[0082] Of course, the end of the left blade 5421 away from the feed outlet 1063 and the end of the right blade 5422 away from the feed outlet 1063 may also be respectively provided with push plate blades 543 .

[0083] When the rotating shaft 109 rotates, a part of the material can be directly pushed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com